Energy absorption type automatically quantitative loading device

A loading device and automatic technology, applied in transportation and packaging, lifting equipment in mines, etc., can solve the problems of old-fashioned mines, complex structure, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

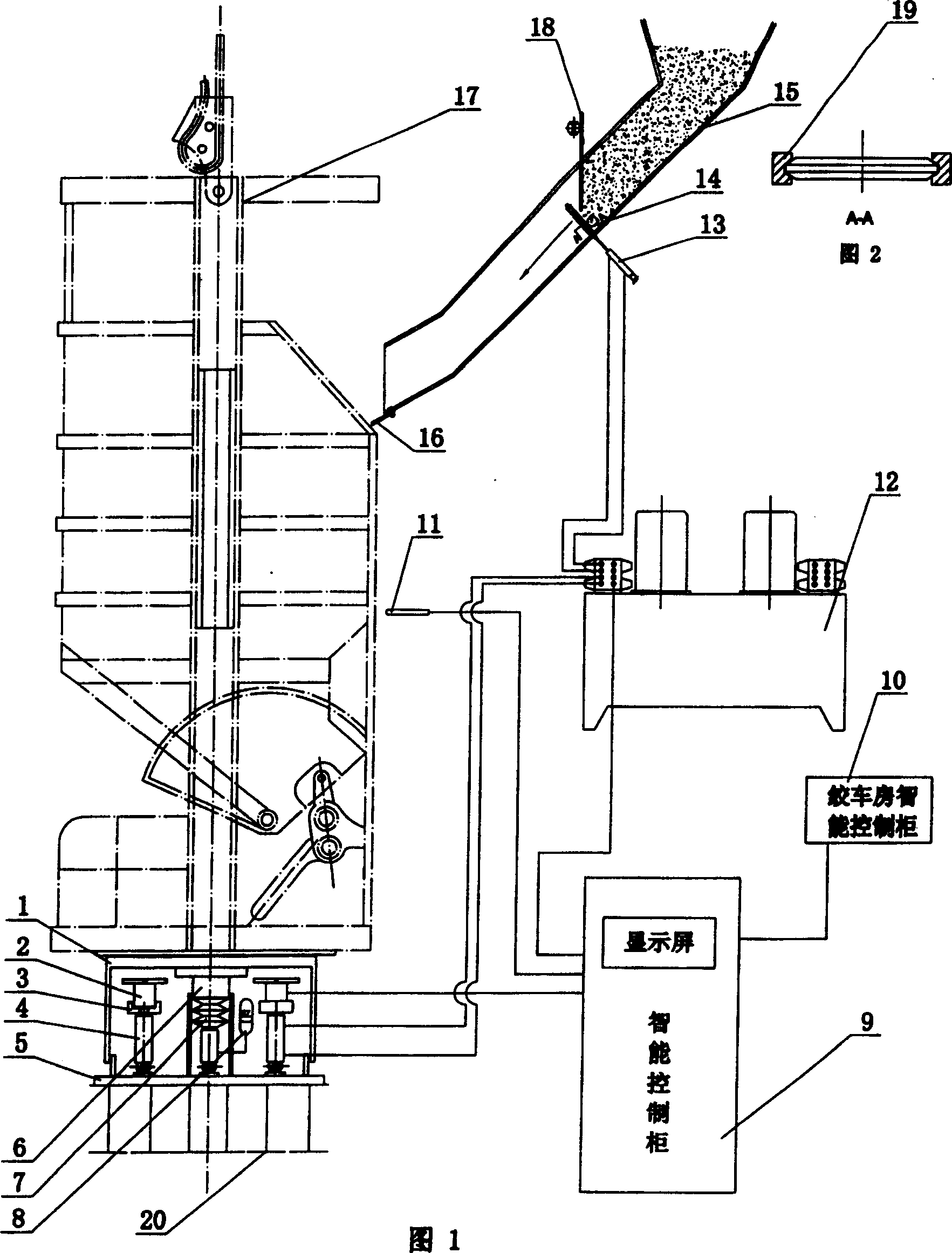

[0012] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0013] The energy-absorbing automatic fixed-weight loading device of the present invention mainly consists of an energy-absorbing fixed-weight device, a coal cutting device, a position sensor 11, a hydraulic station 12, an intelligent control cabinet 9 and an intelligent control cabinet 10 for a winch house. The energy-absorbing fixed weight device is directly installed on the tank support beam 20, and is just in time at the bottom of the skip bucket 17 when the skip bucket 17 falls. The energy-absorbing fixed weight device is composed of an elastic buffer assembly arranged on the base 5 and weighing assemblies arranged on both sides of the elastic assembly. 7 and a hydraulic accumulator 8; the weighing assembly is composed of a load cell 2, a base 3 installed below the load cell 2 and a weighing hydraulic cylinder 4 in sequence. When the skip 17 is in pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com