Electric magnetic suspension conductive board track

A conductive plate and magnetic levitation technology, which is applied in the direction of electric vehicles, track devices, electric traction, etc., can solve the problems of increasing system running resistance and energy loss, so as to increase the ratio of buoyant resistance, reduce electromagnetic resistance, and weaken harmful eddy currents. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

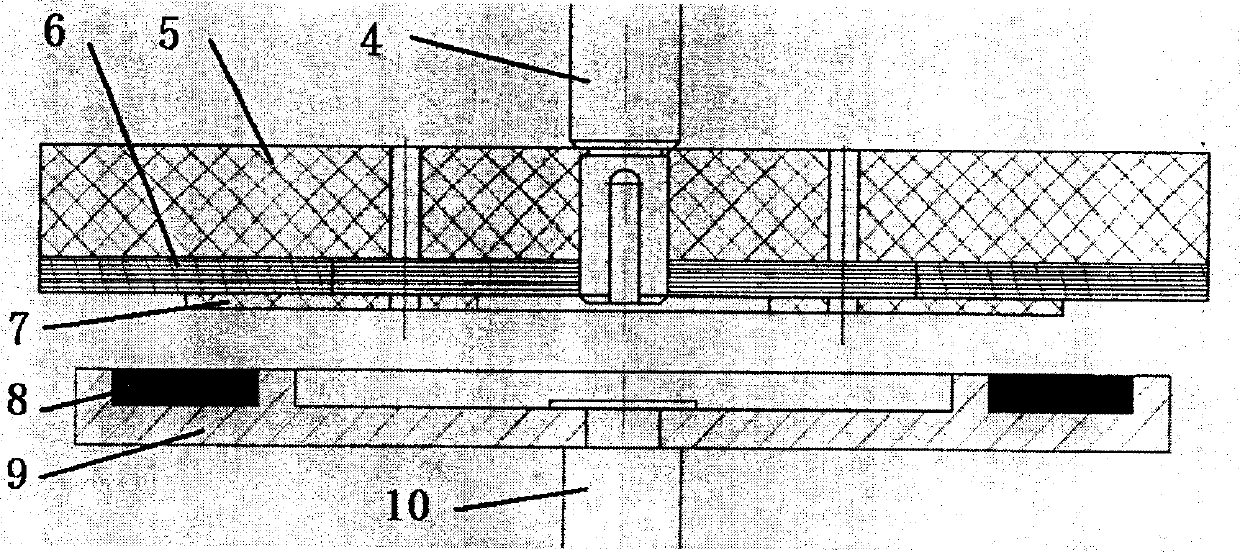

[0011] The present invention will be further described below in conjunction with accompanying drawing.

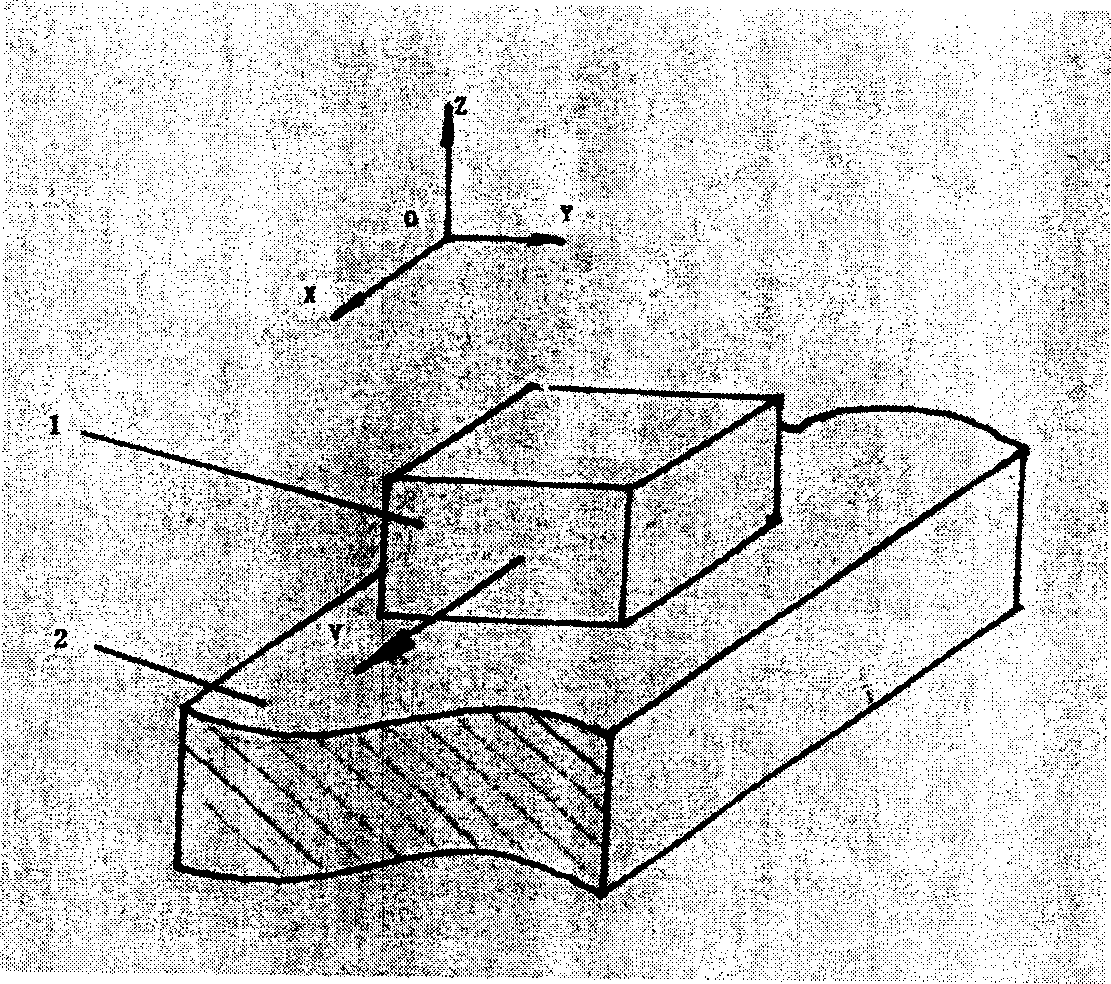

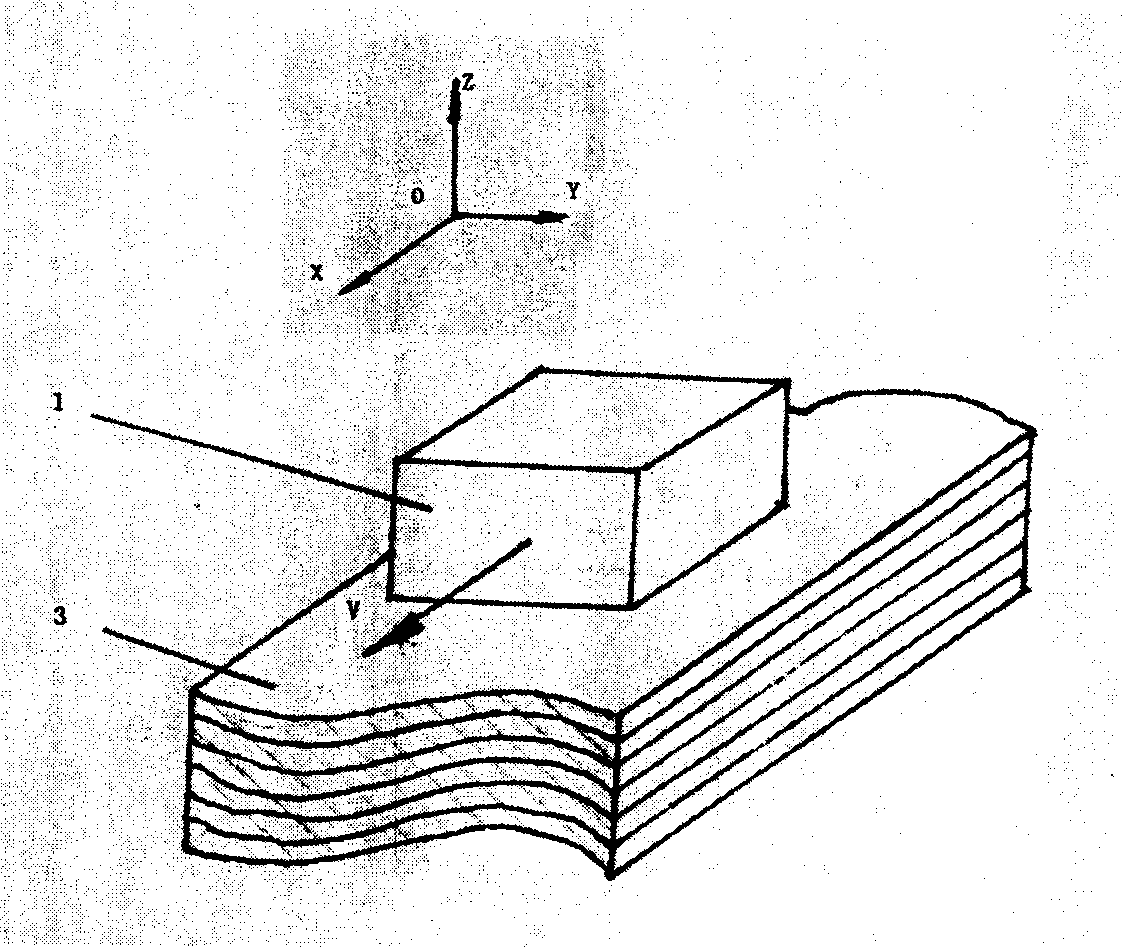

[0012] Such as figure 1 As shown, when the magnet 1 moves relative to the conductive plate 2, the spatial magnetic field B changes, and according to the law of electromagnetic induction, a spatial electric field E is generated, and

[0013] ▿ × E = - ∂ B ∂ t . . . ( 2 )

[0014] where t is time. The inner circuit of the conductor forms an eddy current J, and there is a Lorentz force J×B between it and the magnetic field B of the magnet. According to Lenz's law, the magnetic flux of the induced current resists the change of the original magnetic flux. It can be seen that when the magnet moves, the magnetic flux changes in the XY plane to genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com