Electric incandescent lamp

An incandescent lamp, incandescent body technology, applied in the field of incandescent lamps, can solve the problems of high early failure rate, lamp leakage, short life, etc., and achieve the effect of avoiding strain and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

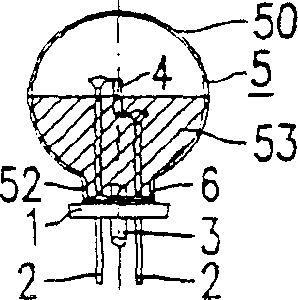

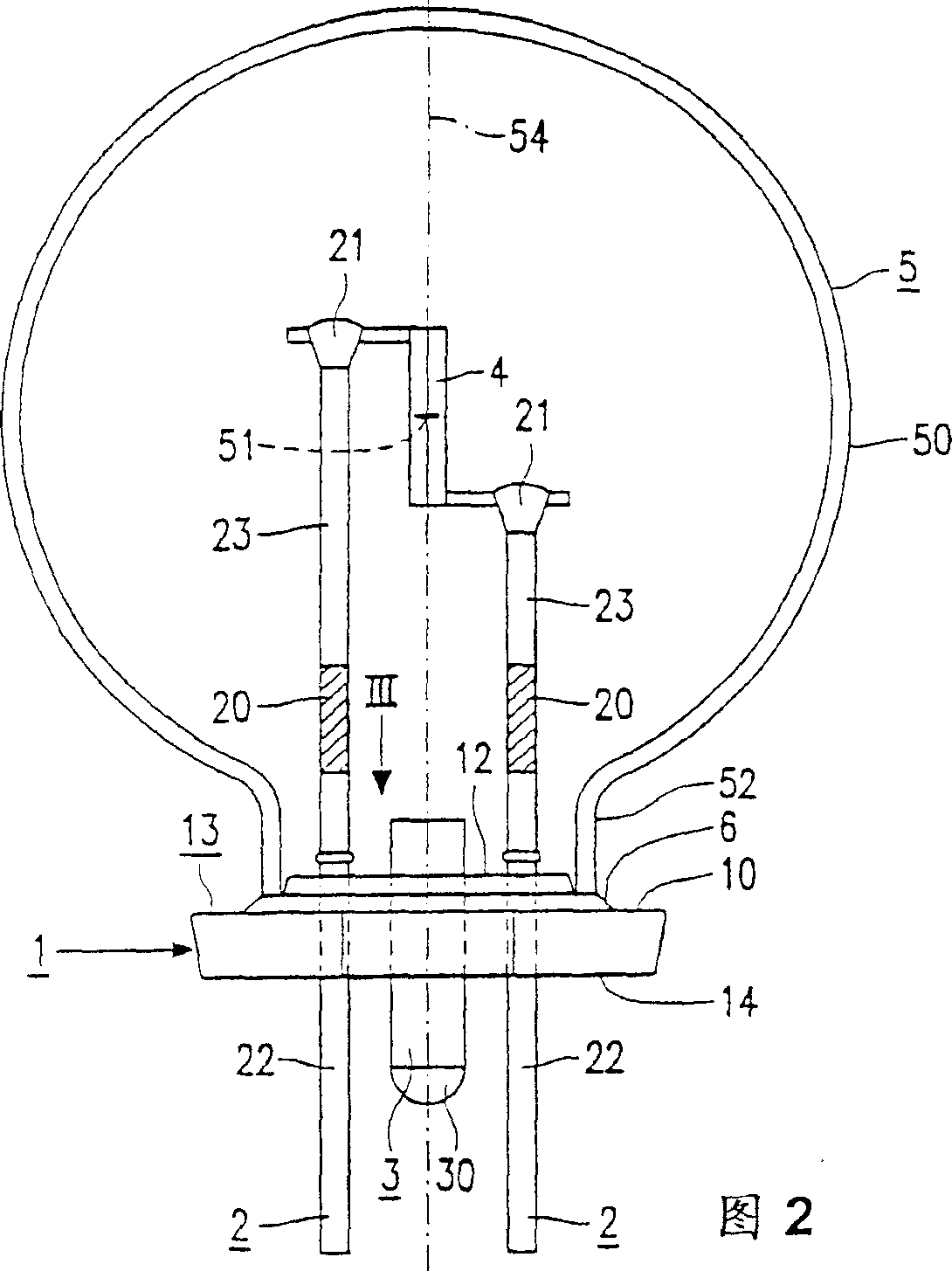

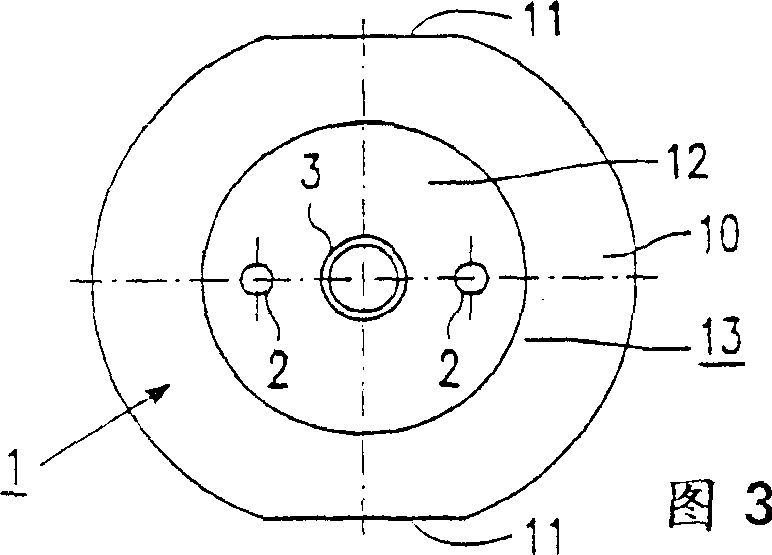

[0033] exist figure 1and 2, the incandescent lamp has a molded glass plate 1 connected in a gas-tight manner to a current conductor 2 and a metal tube 3 passing through said glass plate. The incandescent body 4 is connected to the current conductor 4 and occupies a predetermined position relative to the molded plate 1 . A glass bulb 5 is placed above the incandescent body 4 and is connected to the molded plate 1 in an airtight manner by means of enamel 6 . In the bulb 5 there is a filling gas at a pressure of at least 1 bar. The metal tube 3 has a gas-tight seal 30 outside the bulb 5 .

[0034] The glass pane 1 is a sintered body whose composition corresponds to that of the glass of the bulb 5 . In the accompanying drawings, the composition of the glass is roughly (by weight): SiO 2 , 67.59%; Al 2 o 3 , 3.56%; Li 2 O, 1.27%; Na 2 O, 7.38%; K 2 O, 4.88%; MgO, 1.24%; CaO, 1.89%; SrO, 3.04%; BaO, 8.81%; CeO 2 , 0.12%; SO 3 , 0.17%; the rest 0.05%. Both the glass of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com