Flexible printed wiring board for chip-on-film

A flexible printing, chip-on-film technology, applied in printed circuits, printed circuits, printed circuit manufacturing, etc., can solve the problems of reduced peeling strength of conductive circuits, unclear quality management of the adhesion surface of electrolytic copper foil, etc. Excellent dynamic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

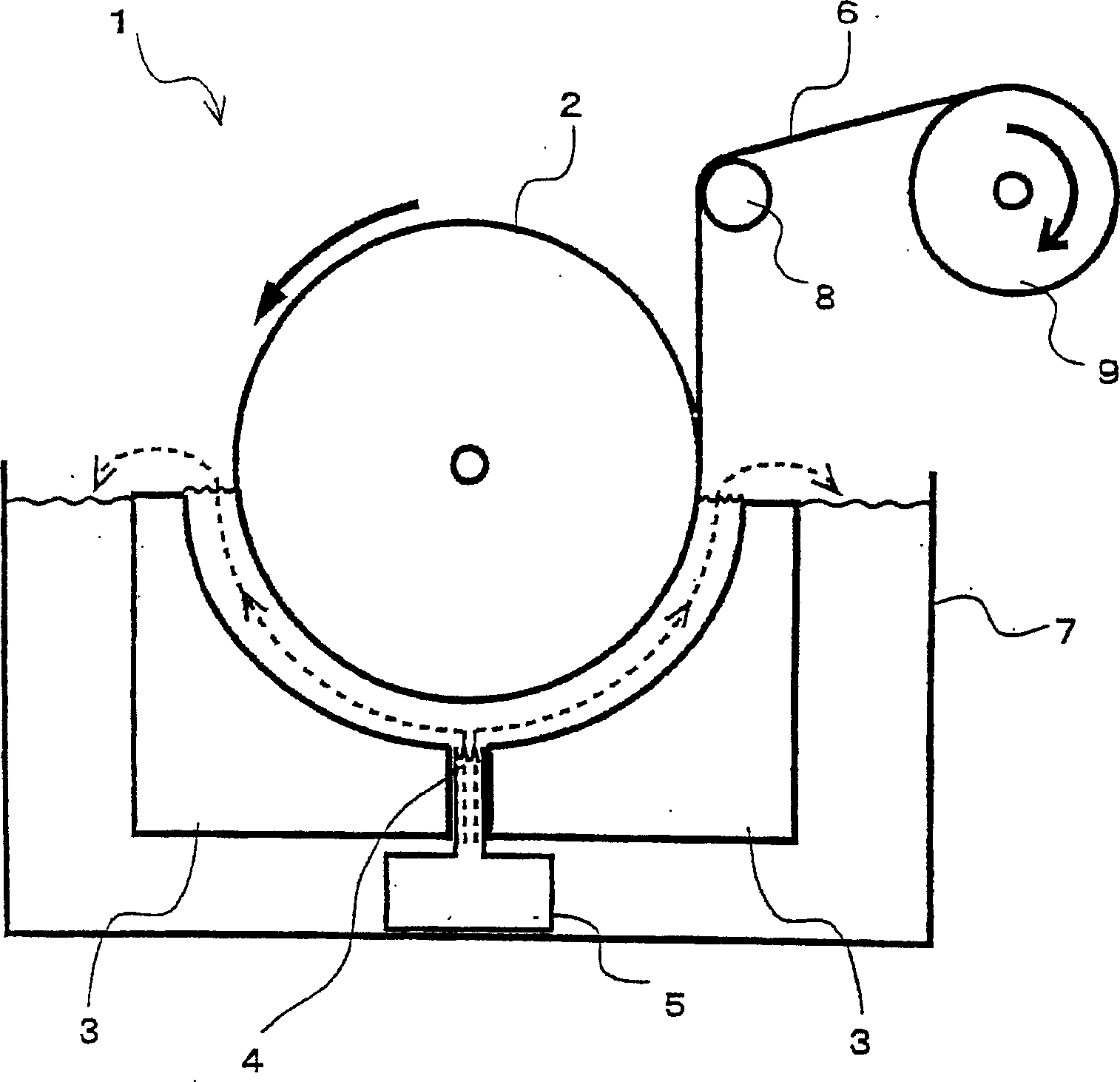

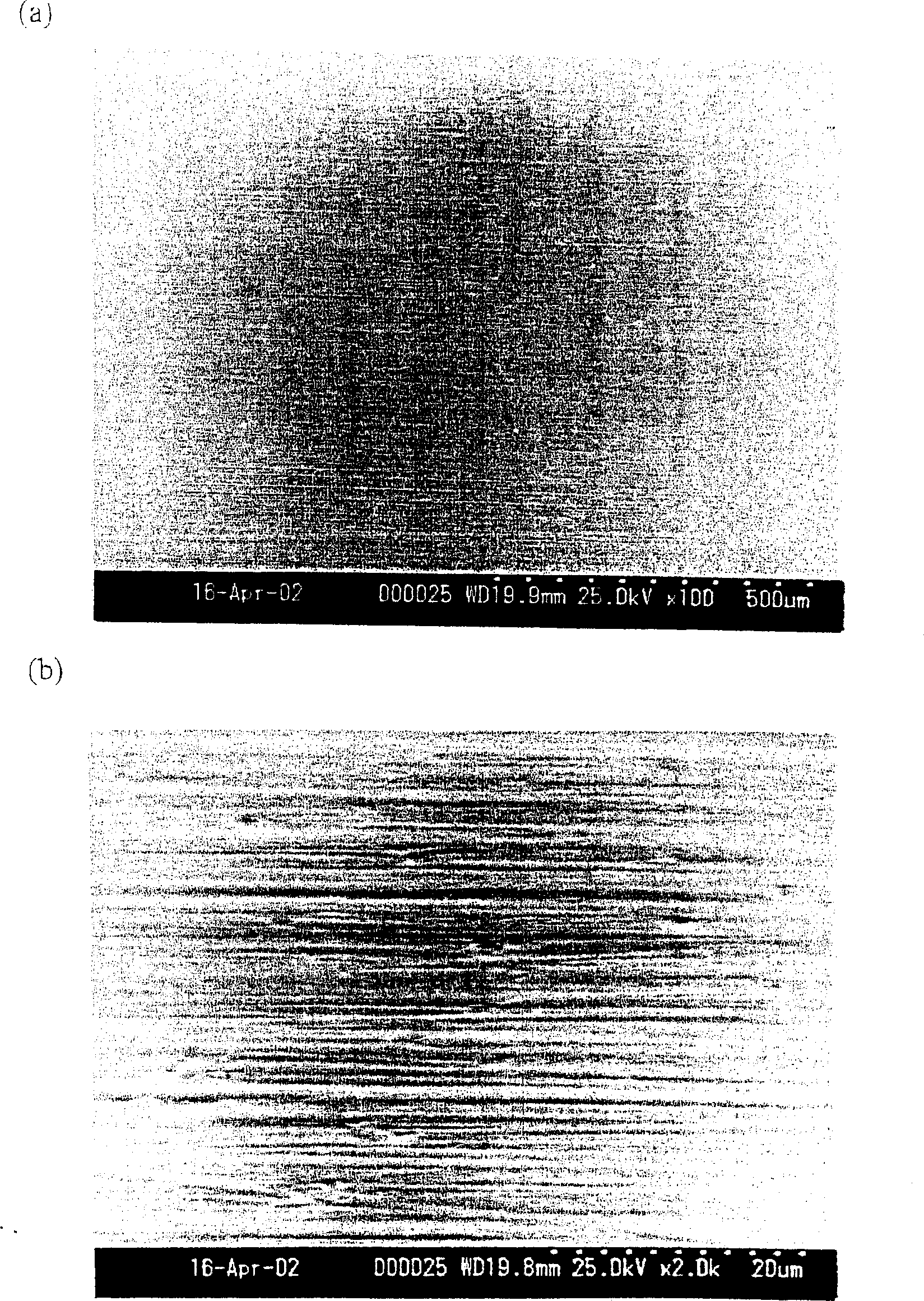

[0034] First, in this embodiment, the description starts from the manufacture of the electrolytic copper foil used for the flexible printed wiring board of the present invention. For the production of electrolytic copper foil, a conventionally known electrolytic copper foil production device using a cylindrical rotating cathode is used, figure 1 A schematic diagram of its cross-section is shown. The electrolytic copper foil manufacturing device 1 is equipped with a titanium cylindrical rotating cathode 2 (3m in diameter and 1.35m in width) for electrodepositing copper, and an insoluble material called DSA is arranged on the opposite side of the rotating cathode 2 along the shape of its peripheral surface. Anode 3. The connection of the rotating cathode 2, the anode 3 and the power supply device is not shown in the figure. Almost half of the cylindrical rotating cathode 2 is immersed in the electrolyte solution, the anode 3 is divided into two, and the electrolyte solution pr...

Embodiment approach 2

[0050] In this embodiment, the results of examining the specular glossiness and light transmittance of the adhesion surface of copper foil according to the type of electrodeposited copper foil and its surface treatment, especially the presence or absence of nodule treatment, will be described. The measurement results of specular gloss and light transmittance of various electrolytic copper foils and copper foils are shown in Table 5.

[0051] Adhesive surface

Specular Gloss

Transmittance%

conductive layer

Coarsening

roughness

Rzμm

Incidence angle 60°

MD

TD

comparative example

A-1

usual foil

rough surface

Have

4.5

1.3

1.1

1.1

comparative example

A-2

low roughness

Foil Rough Side

Have

3.5

1.0

1.0

0.8

comparative example

A-3

low roughness

foil glossy side

Have

2.6

...

Embodiment approach 3

[0070] Finally, with regard to the antirust treatment performed on the adhered surface of the electrolytic copper foil, the results of investigations on the adhesion and anti-flutter properties when forming a flexible printed wiring board will be described.

[0071] The investigation of the adhesiveness of Embodiment 3 used the same electrodeposited copper foil as in Example 3 in Embodiment 1 described above, which were subjected to the respective antirust treatments shown in Table 6. FIG.

[0072] Surface treatment of the adhesive surface

evaluate

Anti-rust treatment

A silane coupling agent

Peel strength

(kgf / cm)

turn black

Transmittance

(%)

type

Adhesion

mg / m 2

type

concentration

normal

state

heating

rear

comparative example

B-1

Zn

36.3

a

5

0.38

0.27

good

73.1

comparative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com