Non-bearing construction mould net

A non-load-bearing, molded net technology, applied in the direction of buildings, building components, building reinforcements, etc., can solve uneconomical problems, achieve simple and fast construction, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

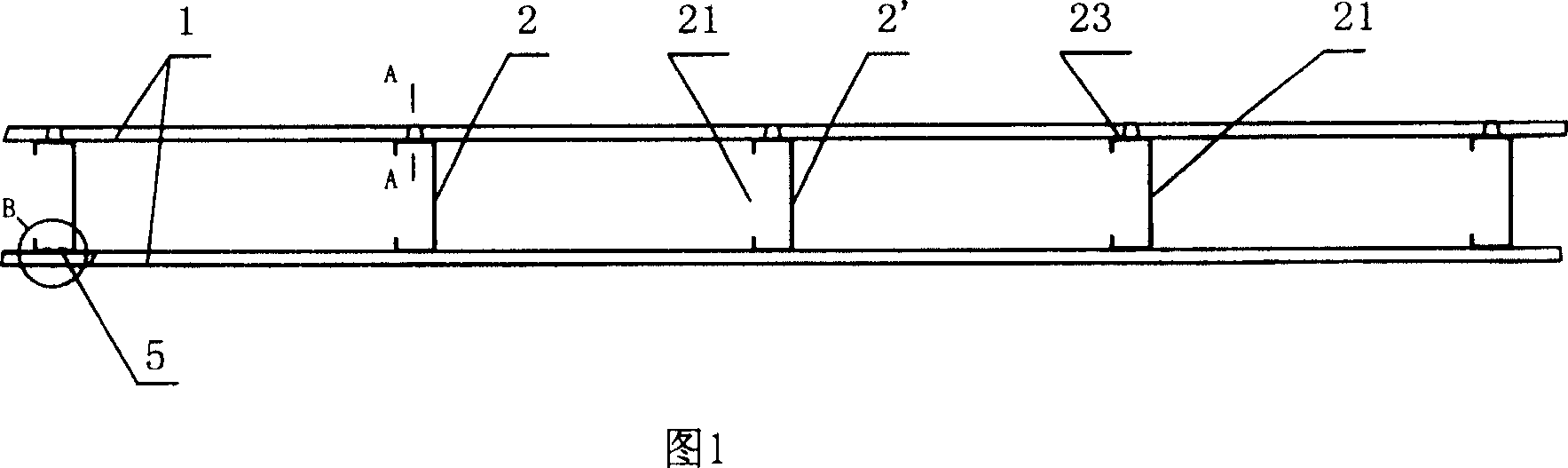

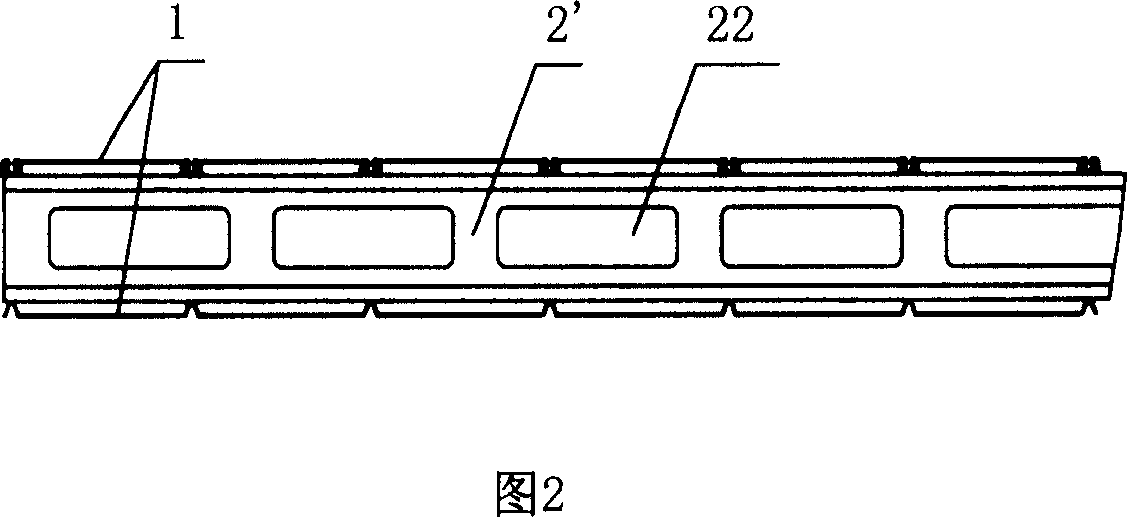

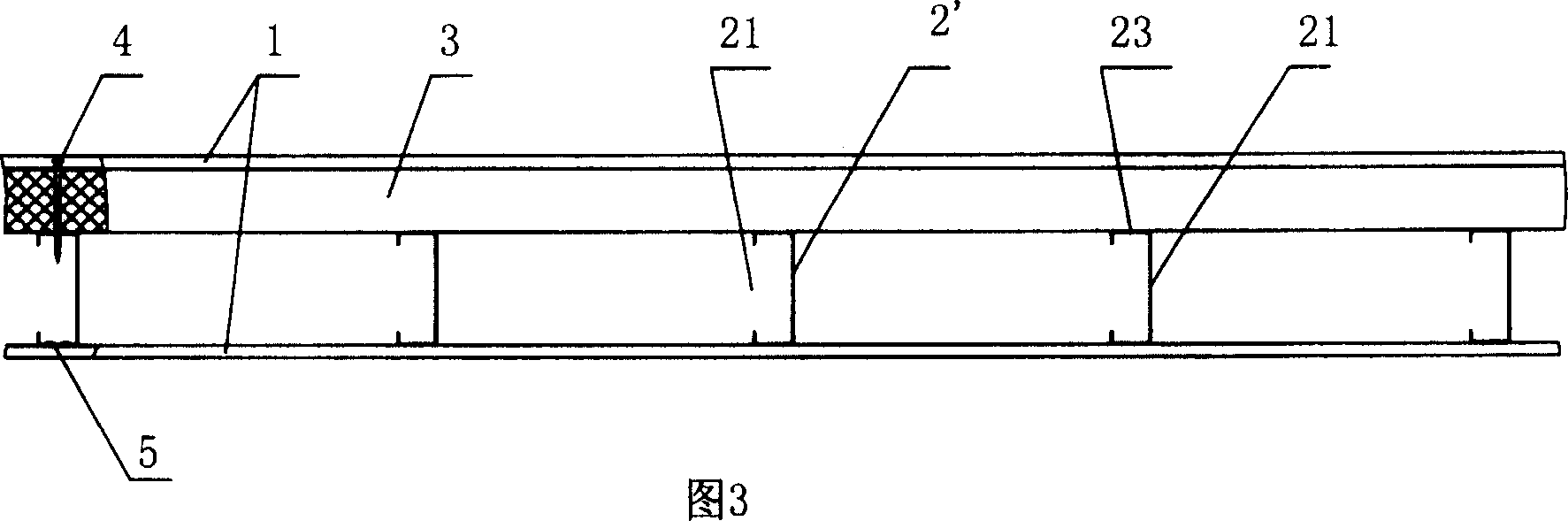

[0033] Referring to Fig. 1, Fig. 2 and Fig. 7, a non-load-bearing building formwork of the present invention is shown in the figure, which includes two steel meshes 1 arranged face to face, and the steel mesh 1 is connected by five longitudinally arranged The parts 2 are fixedly connected together, and the connecting part 2 has a vertical plate arranged approximately perpendicular to the expanded metal surface so that the two expanded metals 1 are separated by a certain distance. In this embodiment, the described connecting part 2 has a cross section of Shaped C-shaped structural member 2', the opening of the C-shaped structural member 2' faces the side, and the vertical plate of the connecting member 2 is the flat web 21 corresponding to the opening side 20 of the C-shaped structural member 2'. The flat web 21 is provided with openings 22 so that the left and right sides of the vertical plate 21 communicate. Fixed connection.

[0034] Referring to Figures 5A and 5B, the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com