A beam-column joint of equal-strength energy-dissipating steel structure

A beam-column joint and steel structure technology, which is applied in building structure, construction, etc., can solve the problems of insufficient beam section strength, increased lateral deformation of the structure, local stability problems, etc., and achieves easy control of construction quality, The effect of solving stress concentration and avoiding brittle failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The description will be further described below in conjunction with the accompanying drawings and embodiments.

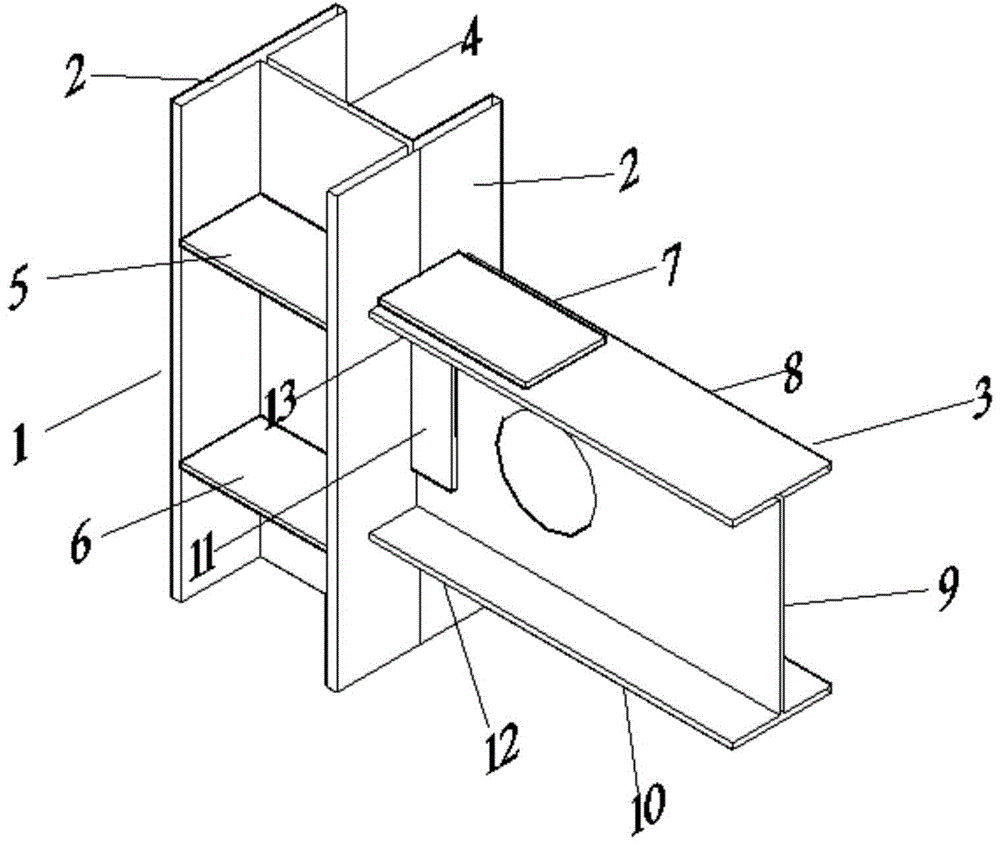

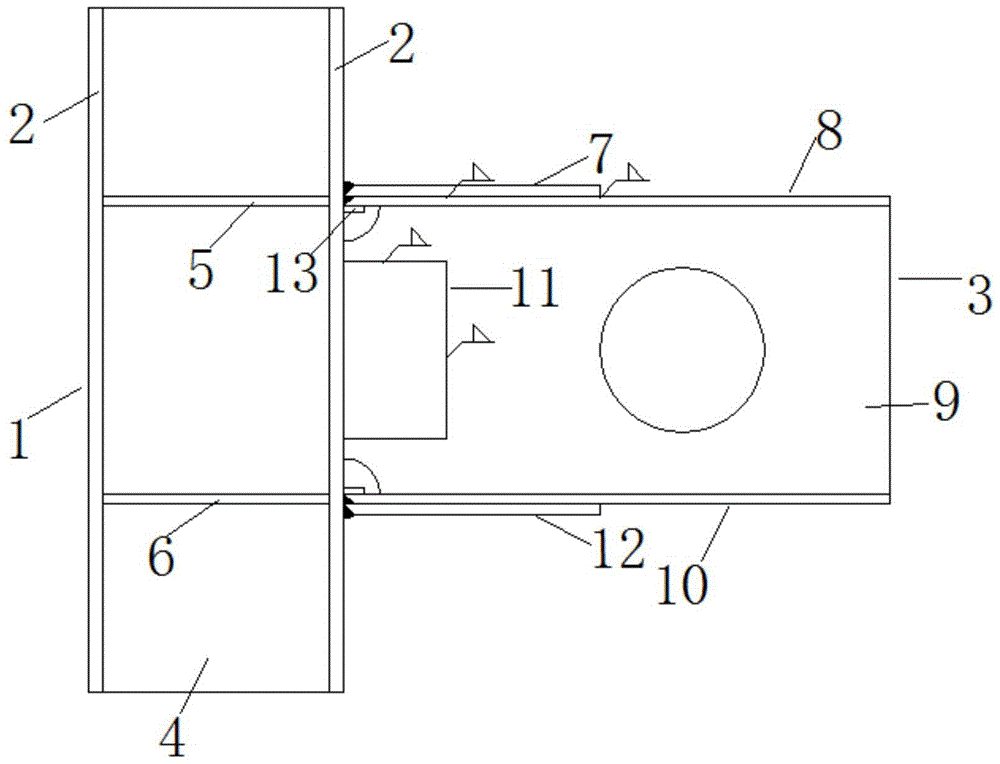

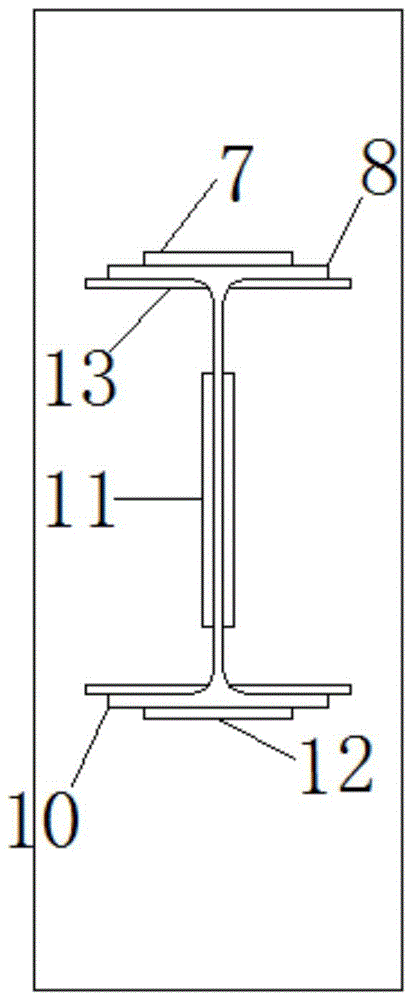

[0030] Such as figure 1 As shown, the present invention provides a beam-column node of an equal-strength energy-dissipating steel structure, including a vertically arranged H-shaped steel column 1, and an H-shaped steel beam 3 connected to its side, wherein: the H-shaped steel column 1 is composed of H-shaped steel The web 4 of the column and the side panels 2 of the H-shaped steel column vertically connected to its two ends constitute the main frame of the H-shaped steel column. Along the two sides of the web 4 of the H-shaped steel column, there are two stiffener plates arranged in parallel up and down. Rib plate a5 and lower rib plate b6; H-shaped steel beam 3 consists of H-shaped steel beam web plate 9 and H-shaped steel beam top side panel 8 and H-shaped steel beam bottom side panel 10 vertically connected at its two ends The H-shaped steel beam main fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com