Wheel bearing on an axle body for vehicles

A wheel and automobile technology, applied in the field of wheel support, can solve the problems of troublesome processing and assembly, expansion of the end section of the shaft tube, etc., and achieve the effect of eliminating welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

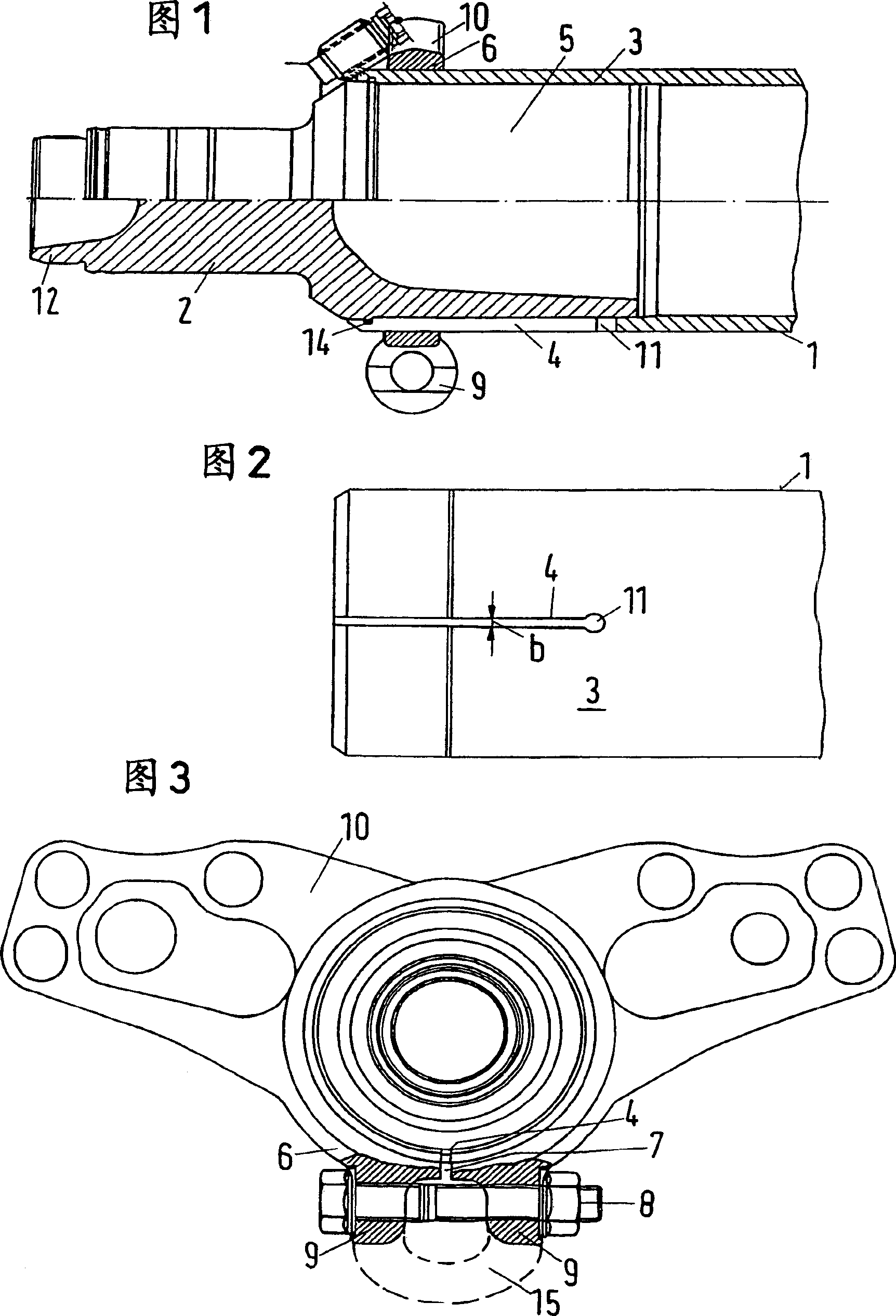

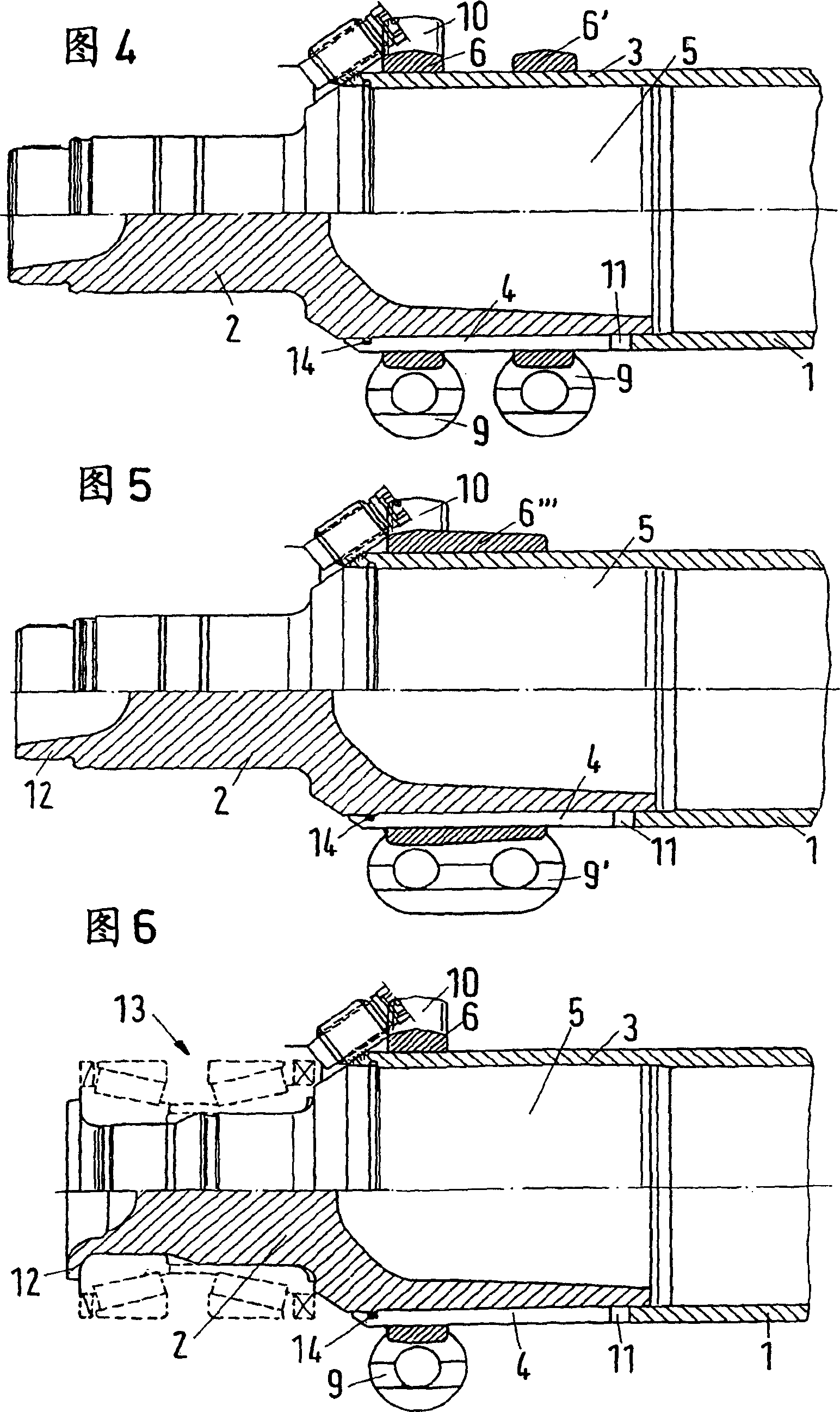

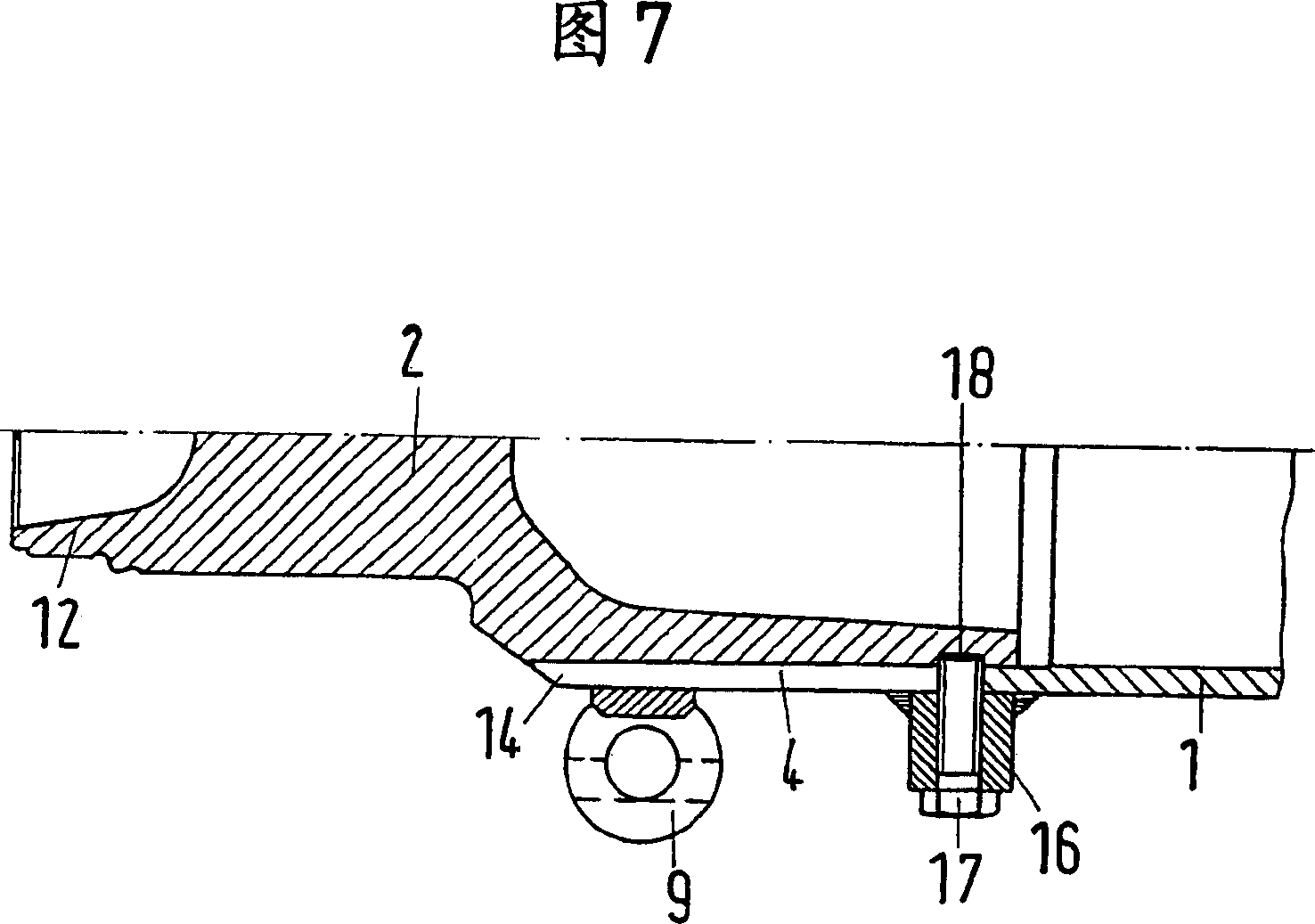

[0020] The wheel bearing according to the invention is arranged according to FIG. 1 on an axle body formed by an axle tube 1 for a motor vehicle, in particular a commercial vehicle. For such a wheel mounting, the (not shown) wheel is fastened, for example via (likewise not shown) wheel bolts, to a hub (not shown) which is rotatably mounted on the journal 2 of the axle tube 1 . The journal 2 is radially clamped as a separate structural part to the end section 3 of the shaft tube 1 . To this end, the end section 3 of the shaft tube 1 is designed as an inner cylinder. The end section 3 is provided with at least one axis-parallel longitudinal slot 4 . The journal 2 fits in the end section 3 of the shaft tube 1 via an external likewise cylindrical connecting section 5 , wherein the end section 3 of the shaft tube 1 and the connecting section 5 of the journal 2 pass through at least one A clamping ring 6 , which is continuously slotted in the longitudinal direction, clamps radiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com