Construction method of long auger drilled grouting pile with medium hole vibrating casing retaining wall

A technology of long spiral drilling and construction method, which is applied in the field of building foundation engineering, can solve the problems of low excavation requirements, frequent safety accidents, uneconomical and other problems, and achieve the avoidance of hole collapse accidents, vertical bearing capacity and horizontal Enhanced shear resistance and time-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

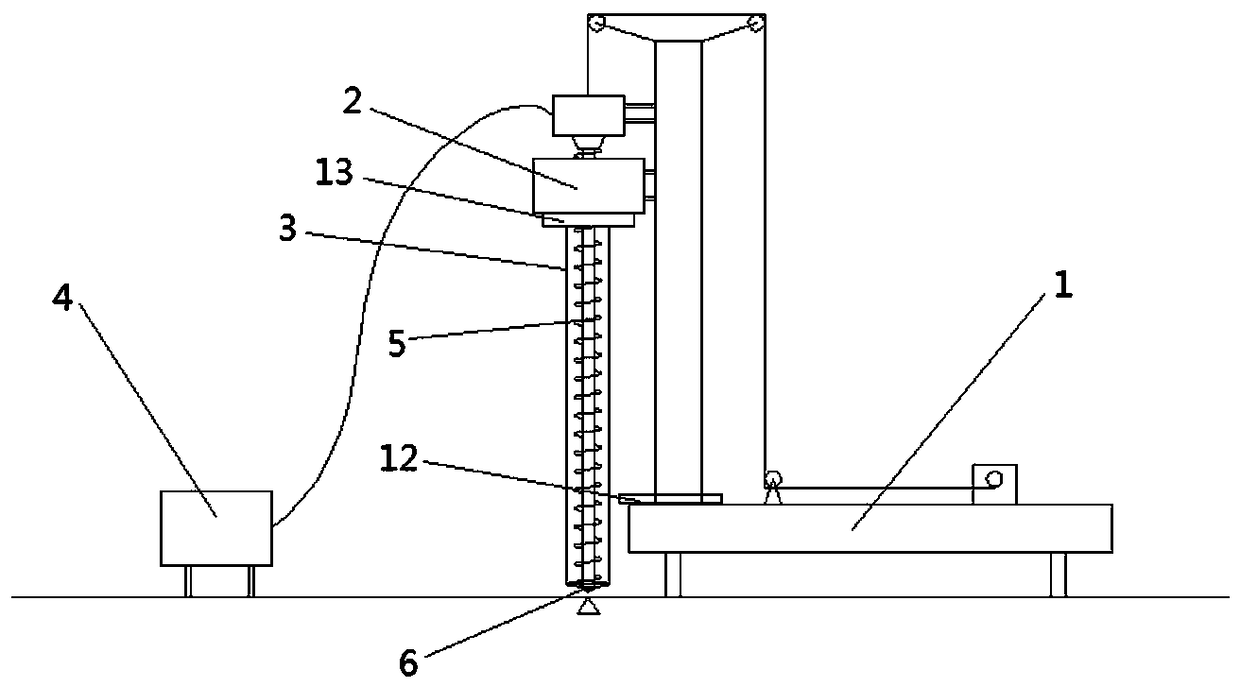

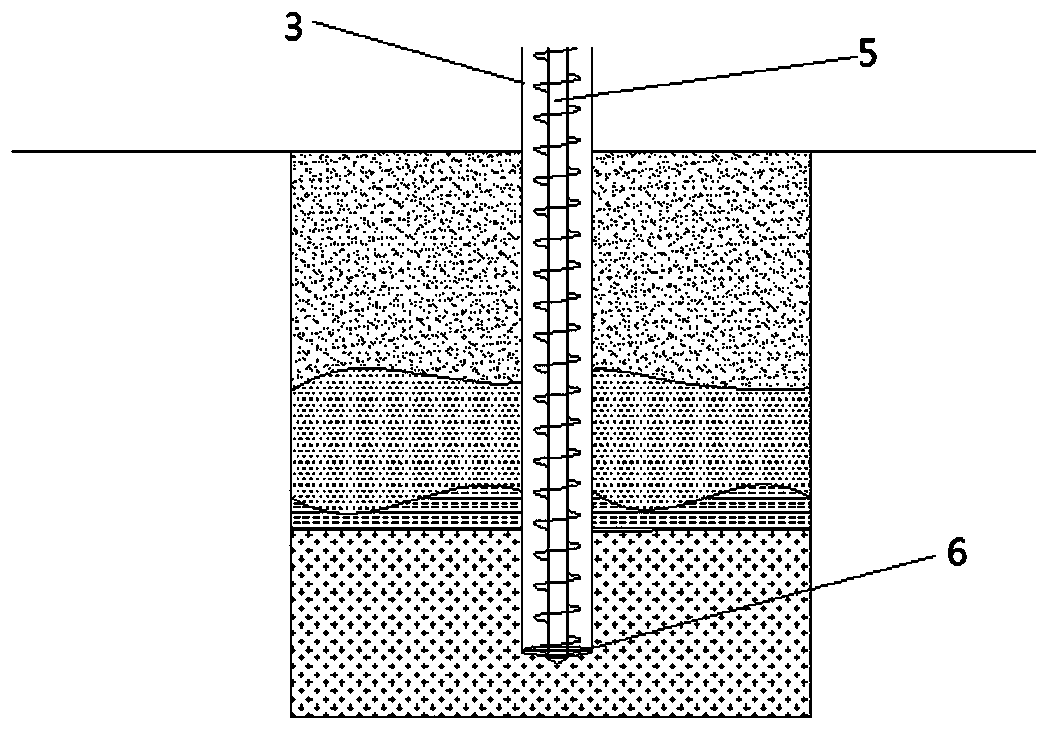

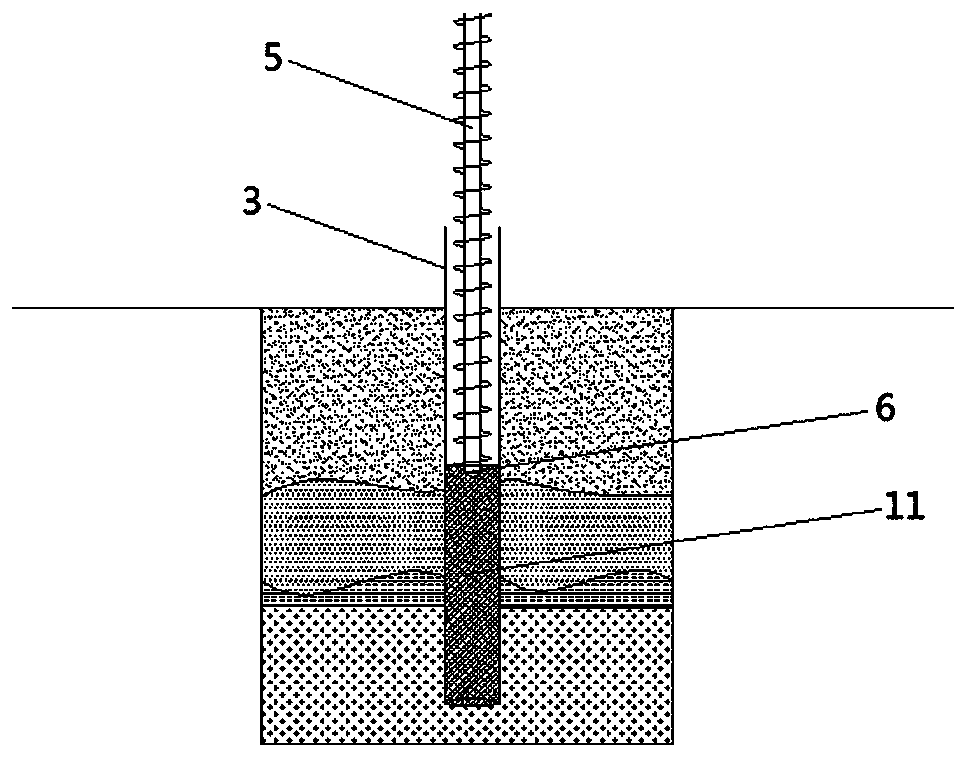

[0031] Example 1, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, the main mechanical equipment and accessories required for the construction of long auger drilled grouting piles with vibrating casing walls in the middle hole include: long auger drilling machine 1, vibrating hammer for middle hole 2, casing 3, tendon inserter 8, small vibration Hammer 7; auxiliary mechanical equipment includes: crane 10, concrete delivery pump 4, excavator. The installation and connection of mechanical equipment includes: the long auger rig 1 connects and drives the auger rod 5 and the drill bit 6; the long auger rig is provided with a cleaner 12, and the middle-hole vibratory hammer 2 clamps the casing 3 with a hydraulic clamp 13. The auger drill pipe 5, drill bit 6, center hole vibratory hammer 2 and casing 3 overlap in the axial direction; the small vibratory hammer 7 is connected to and drives the rib inserter 8; the concrete delivery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com