Fixing device

A fixing roller and cylinder technology, which is applied in the field of fixing devices, can solve the problems of increased power consumption, temperature rise of the fixing belt, thermal offset of color materials, etc., and achieves the effects of reducing energy consumption, small fixing power, and short printing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

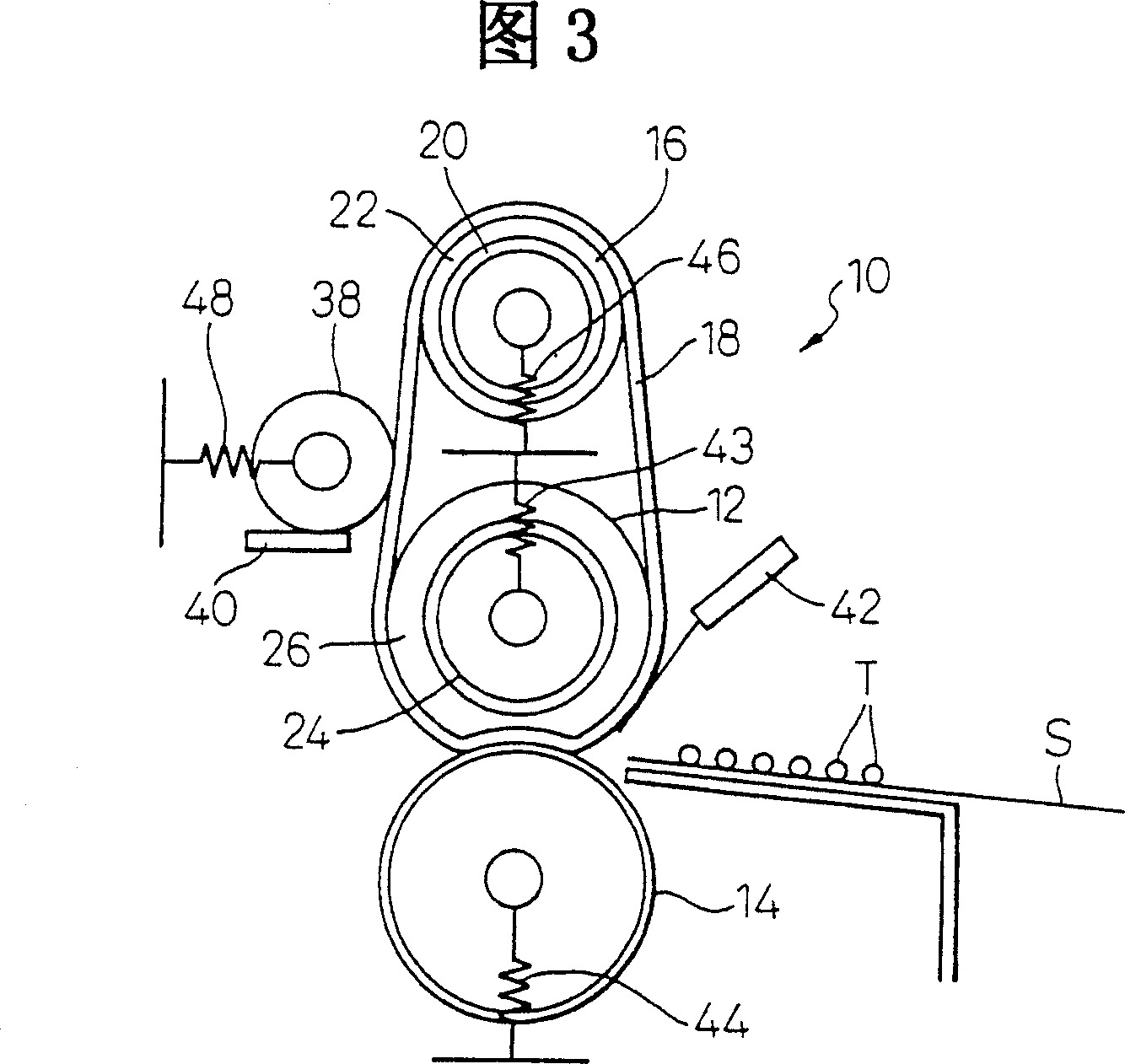

[0061] The invention will be described below with reference to the embodiments shown in the drawings.

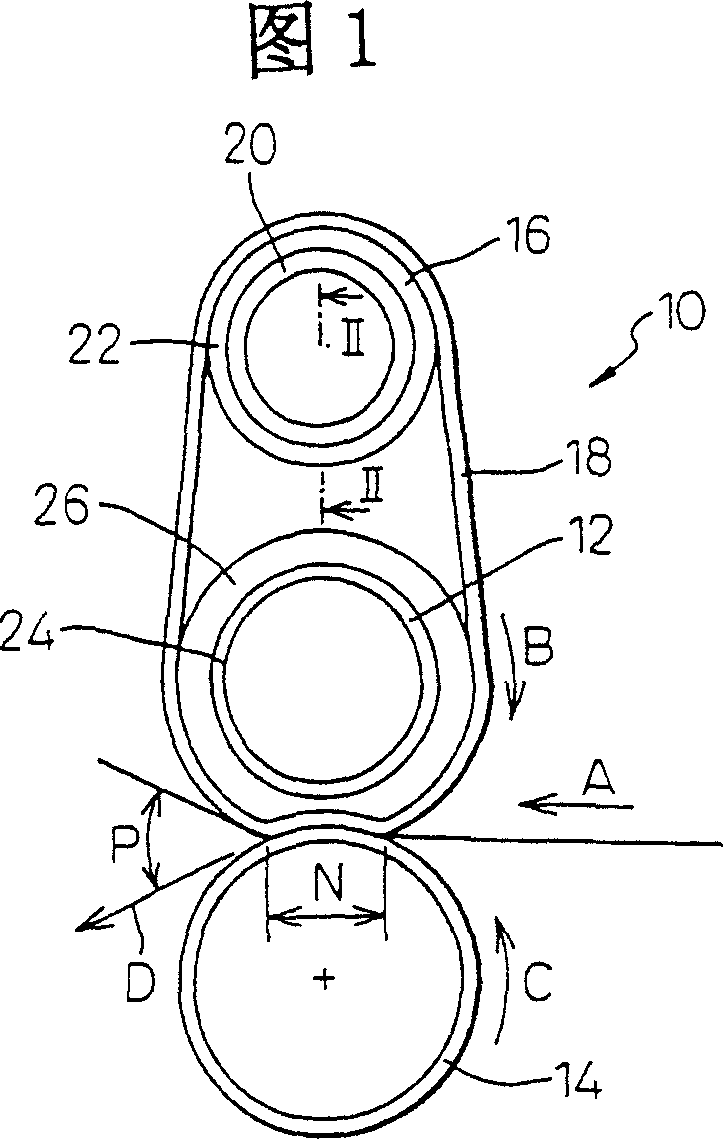

[0062] FIG. 1 is a cross-sectional view showing a fixing device 10 according to a first embodiment of the present invention. The fixing device 10 is arranged inside an electrophotographic device (copier, facsimile, printer, etc.). An electrophotographic device (copier, facsimile machine, printer, etc.) includes an image forming device (not shown) for forming (or reproducing) an image on a form. The form on which the image is formed (or reproduced) is conveyed from the image forming device to the fixing device 10 as indicated by arrow A, for example.

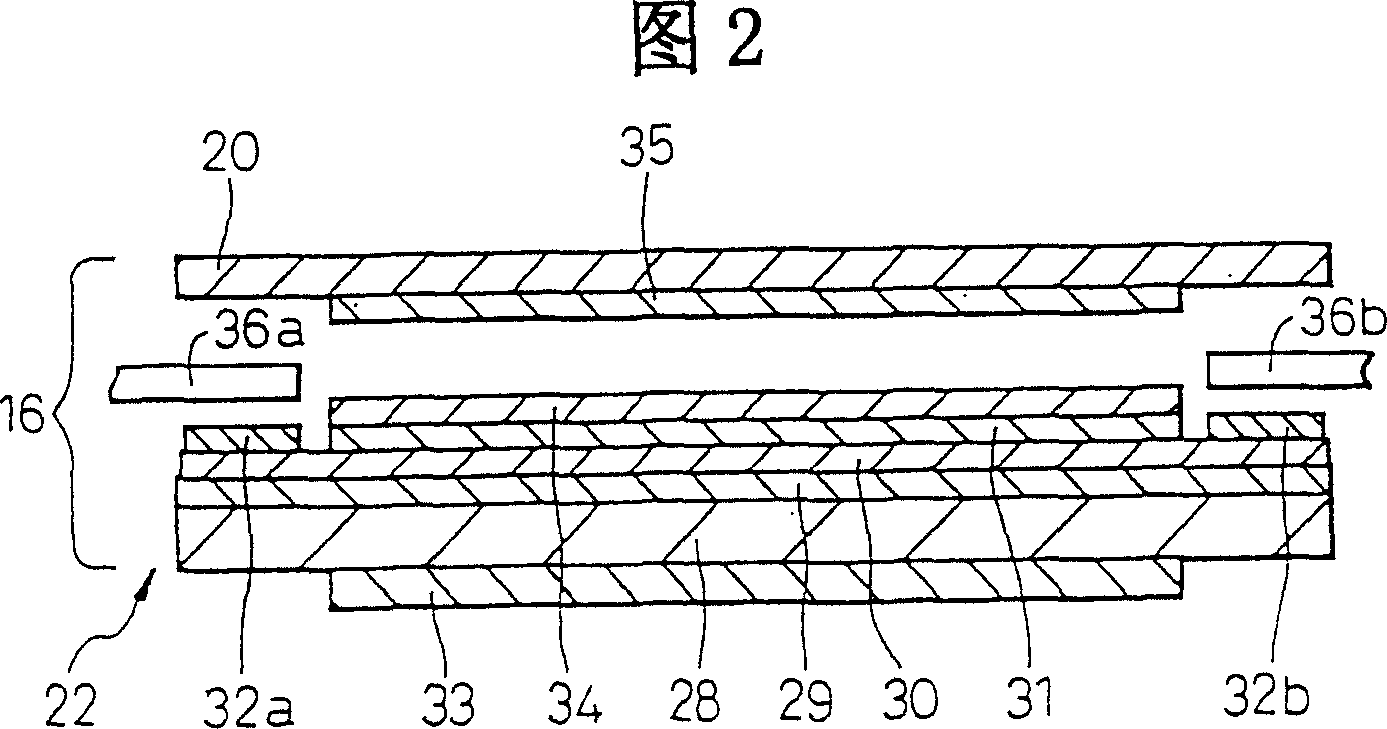

[0063] The fixing device 10 includes a fixing roller 12 , a pressure roller 14 arranged to be in contact with the fixing roller 12 , a third roller 16 arranged parallel to the fixing roller 12 , and a fixing belt 18 wound around the fixing roller 12 and the third roller 16 . . The third roller 16 includes a cylindrical tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com