Discharge lamp lighting method and discharge lamp lighting apparatus

A discharge lamp and equipment technology, applied in the field of discharge lamp lighting equipment, can solve problems such as complex circuit structure, achieve the effect of simplifying the circuit structure and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

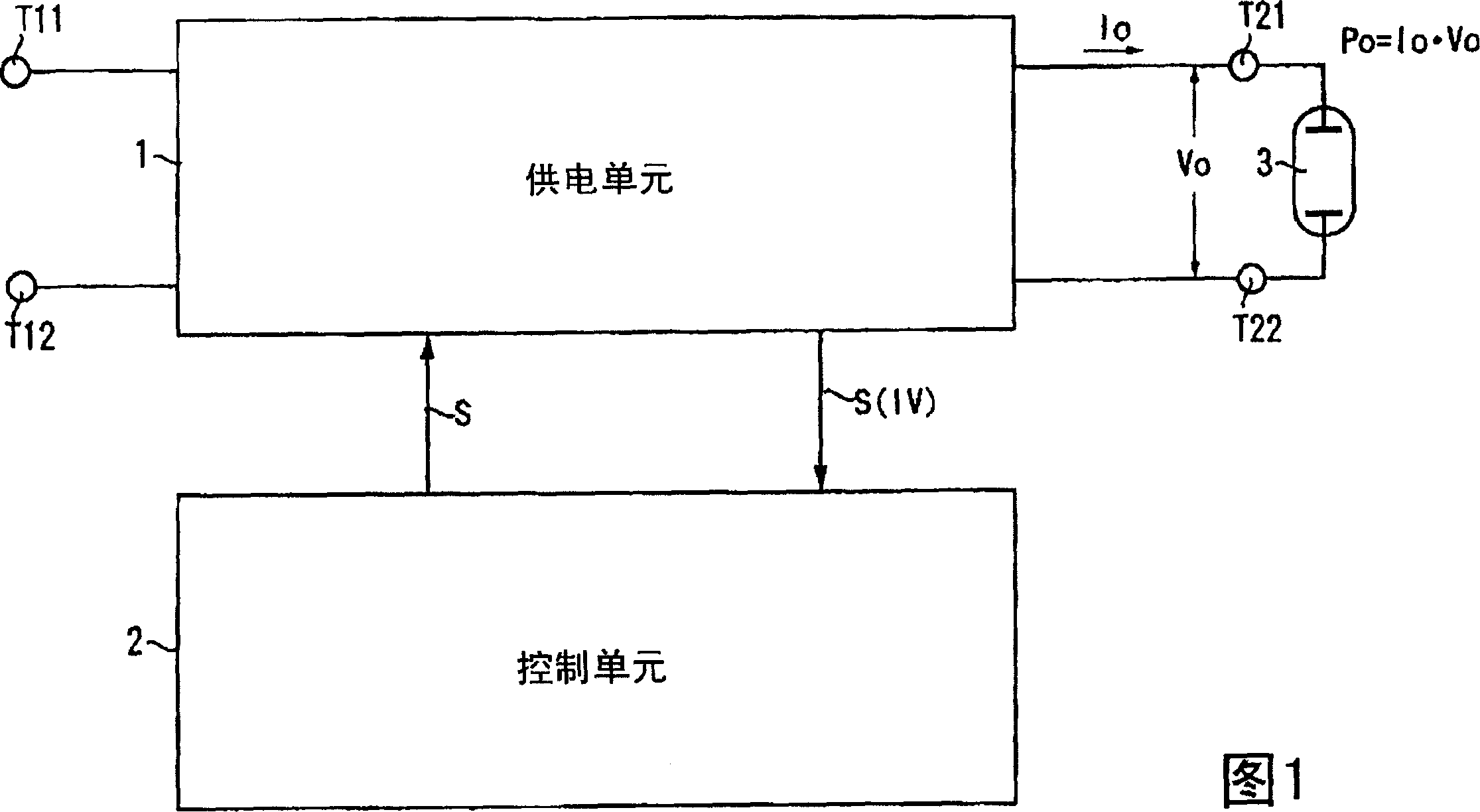

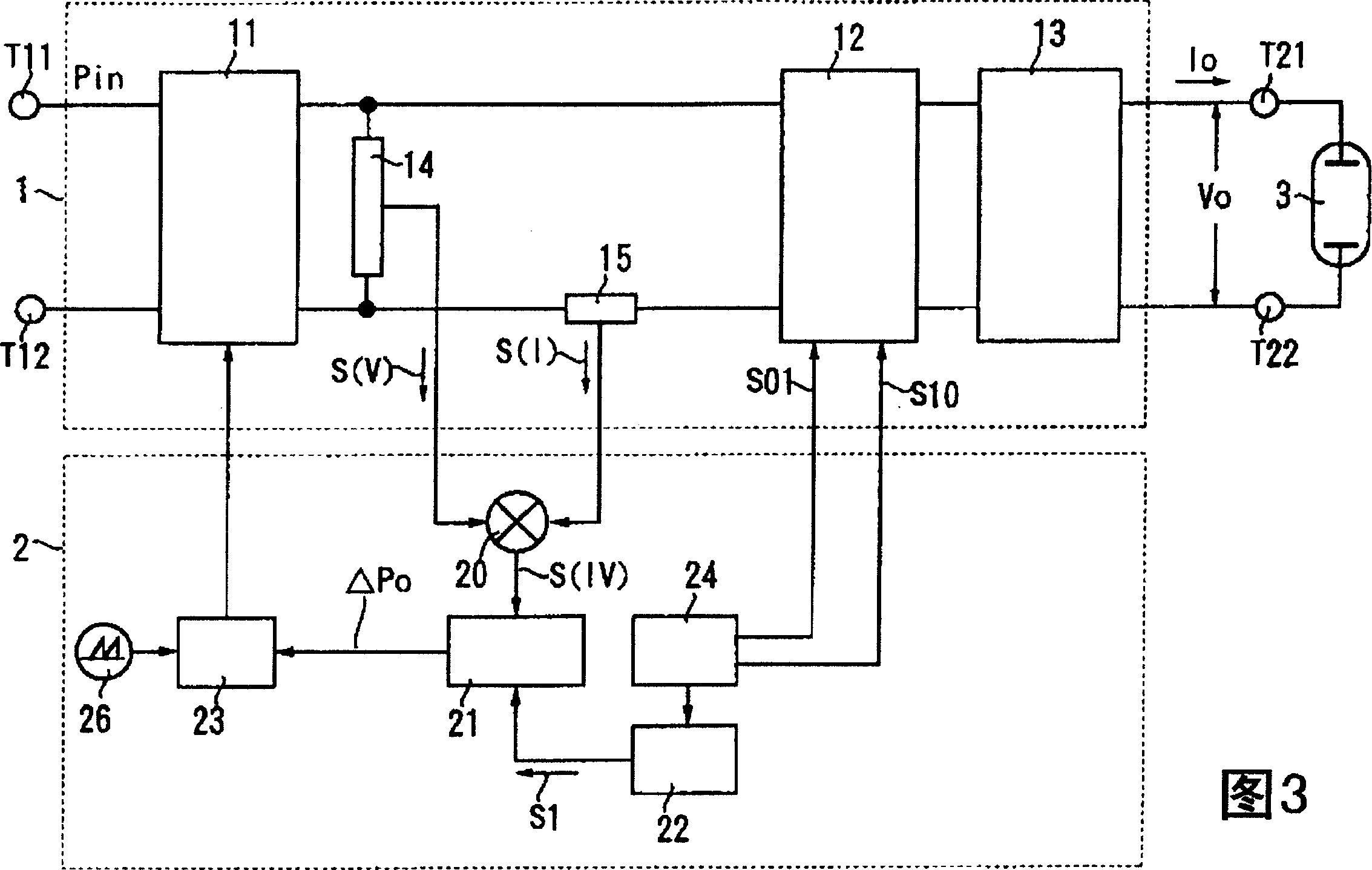

[0022] Fig. 1 is a block diagram of a structure employed in a discharge lamp lighting apparatus according to the present invention. The discharge lamp lighting device in this figure includes a power supply unit 1 and a control unit 2 . The power supply unit 1 supplies AC power (Po) to the discharge lamp 3 . DC power is normally supplied to the input terminals ( T11 ) and ( T12 ) of the power supply unit 1 . The power supply unit 1 converts this DC power into AC power at its internal power conversion circuit and supplies the resulting AC power to output terminals ( T21 ) and ( T22 ). The discharge lamp 3 whose both ends are connected to the output terminals ( T21 ) and ( T22 ) receives AC power (Po) supplied from the output terminals ( T21 ) and ( T22 ). If the power supply unit 1 is provided on its input side with a power conversion circuit for converting AC to DC, AC power can be input to the input terminals ( T11 ) and ( T12 ).

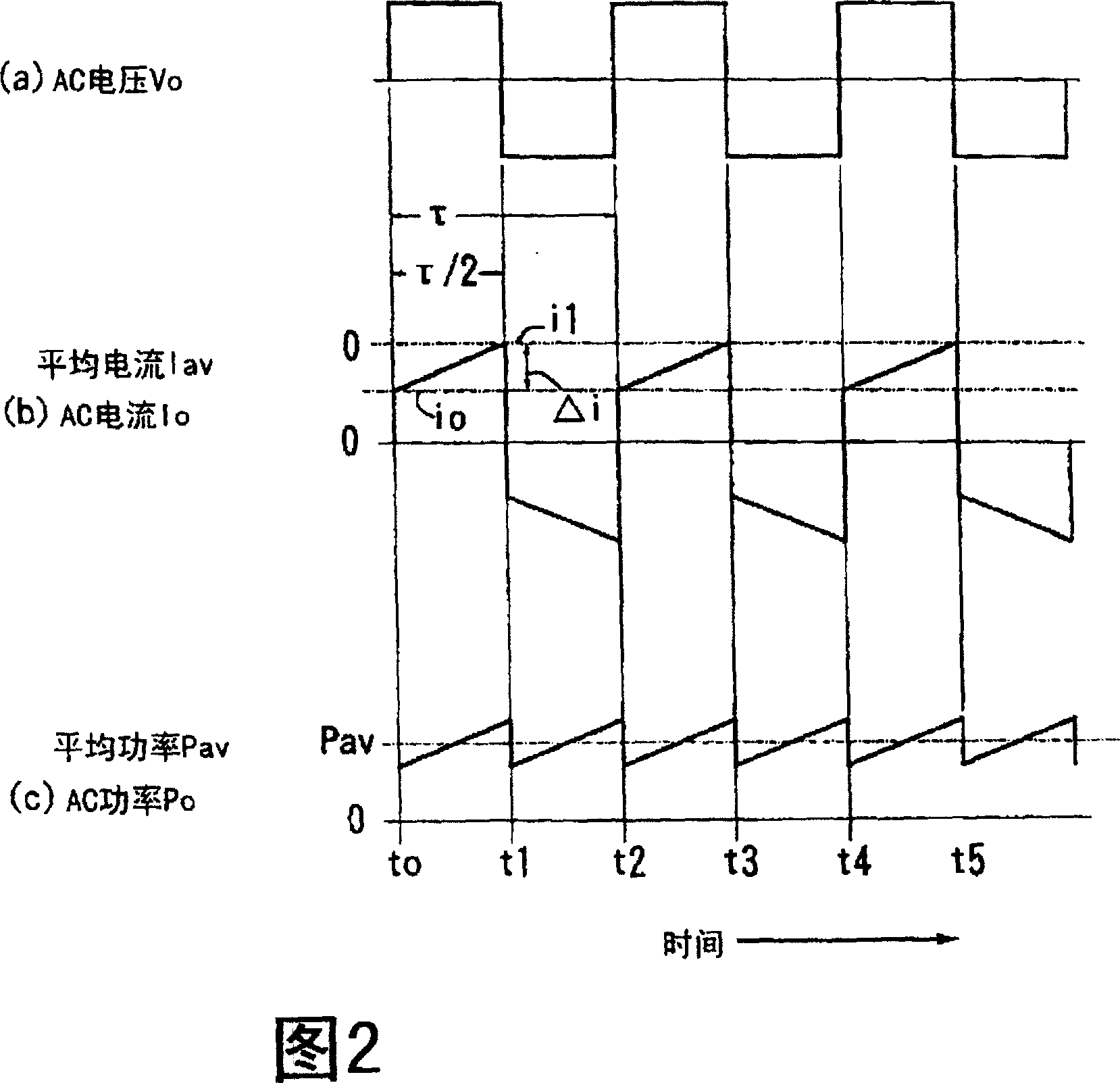

[0023] Figure 2 (a) shows the waveform of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com