Servo control valve

A technology for controlling valves and valve sleeves, applied in the field of servo control valves, which can solve problems such as the increase of price actuators, and achieve the effect of continuous and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

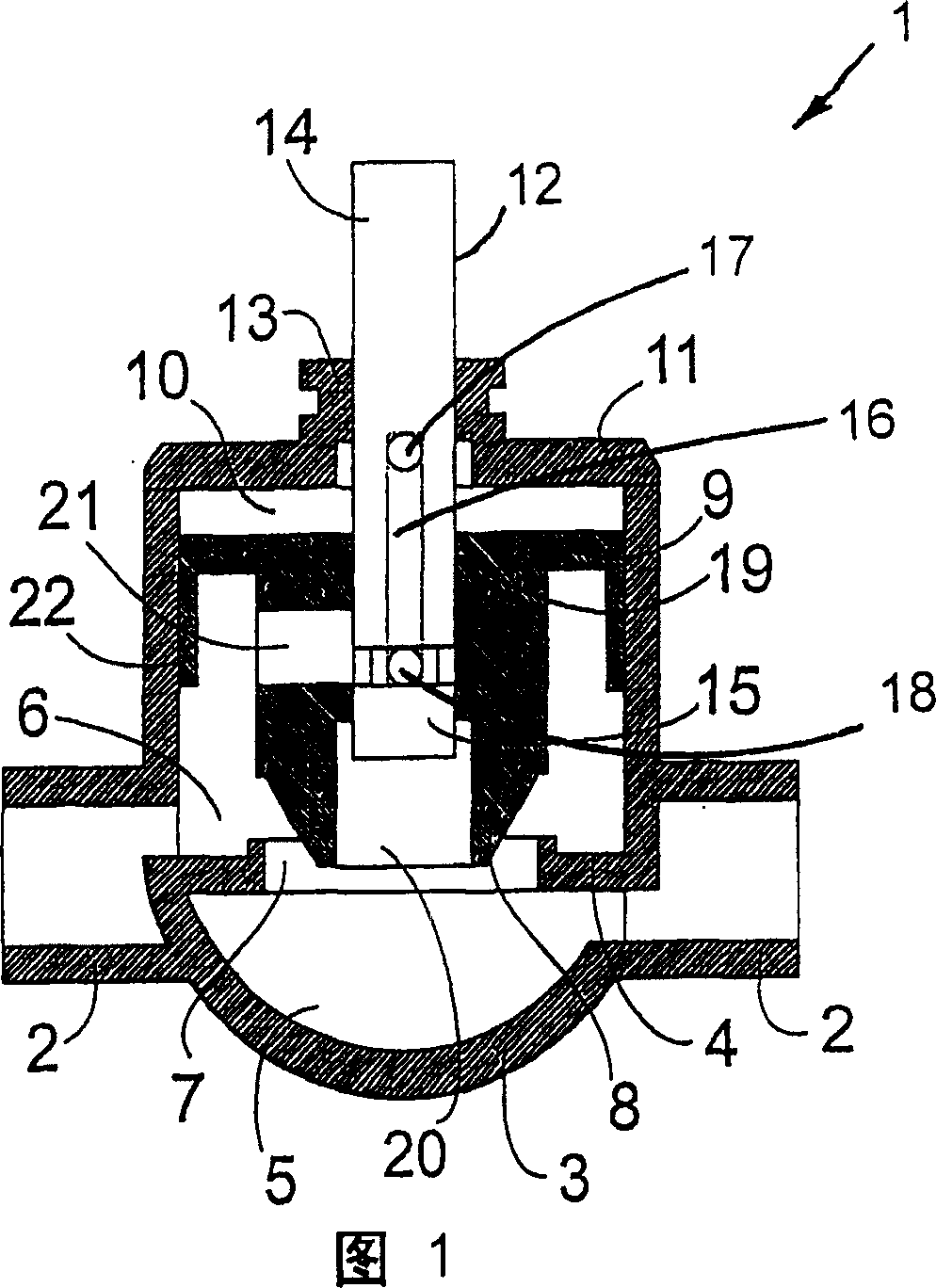

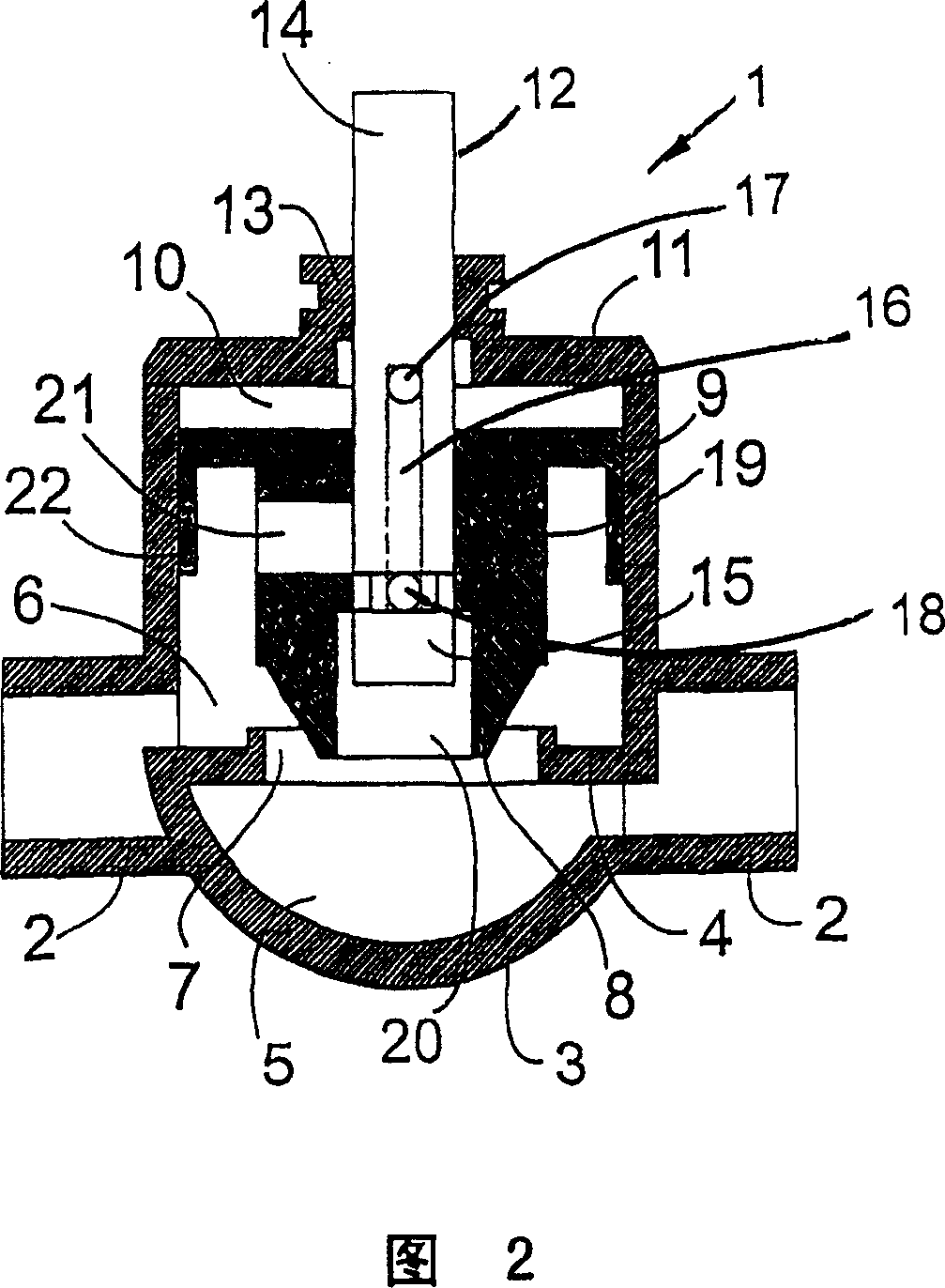

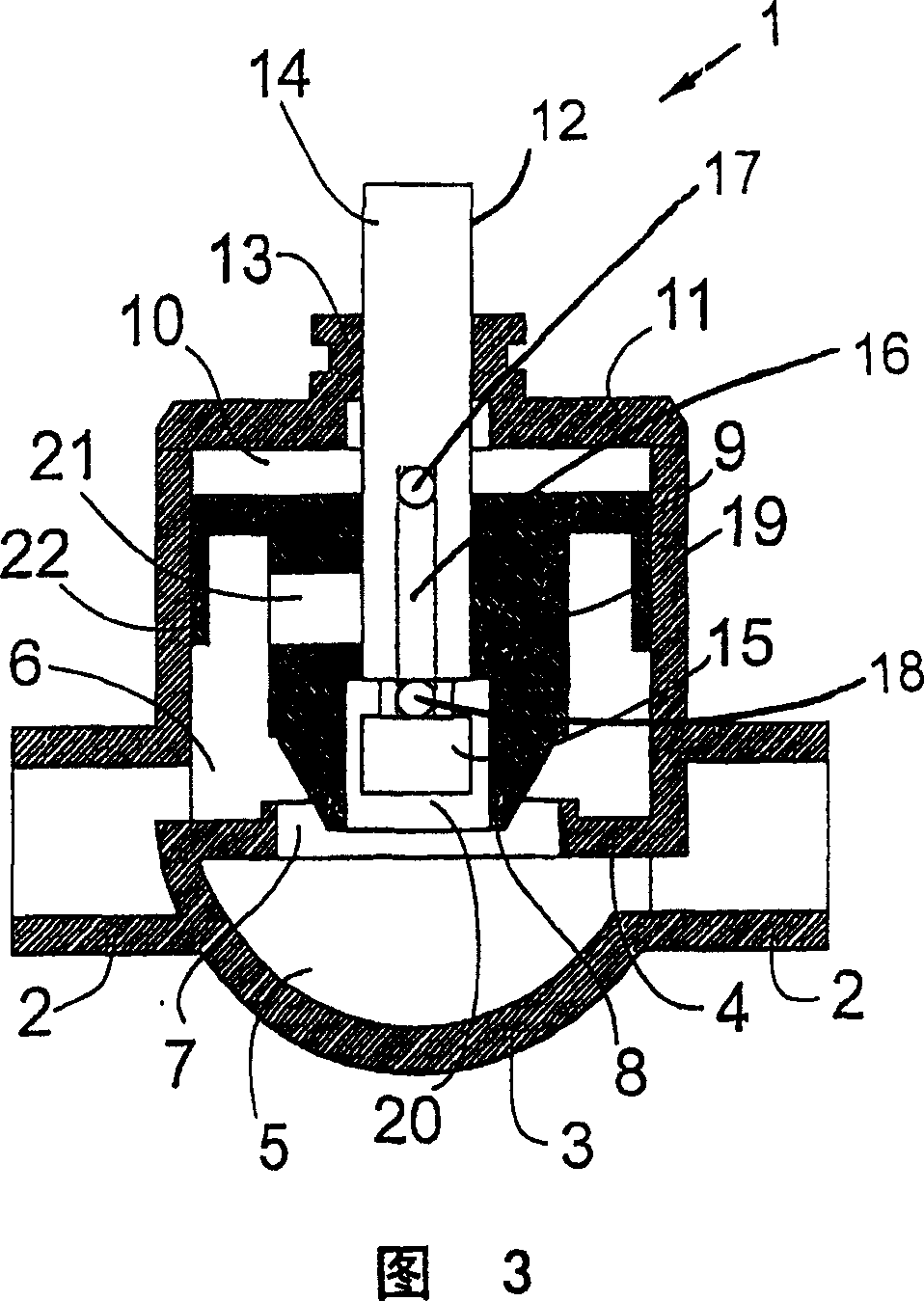

[0039] It is assumed below that the control valve is connected to the supply pipe of the radiator (not shown in the figure). As shown in the figure, the radiator is connected to the left section of the pipe. As shown by the arrow, the water flows through the valve from right to left.

[0040] In FIGS. 1-5, the control valve is generally indicated by the reference number 1, and the supply pipe, which is only partially shown, is generally indicated by the reference number 2.

[0041] The valve has a valve sleeve 3 divided into a first part 5 and a second part 6 by a partition 4. The two parts 5, 6 are respectively located upstream and downstream of the valve connected to the pipeline 2.

[0042] In addition, the partition 4 has a fluid through hole 7 through which water in the radiator can flow.

[0043] According to conditions such as room temperature, by keeping a sufficient distance from the fluid through hole, the valve cone 8 on the movable plunger 9 functions to close the flui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com