Apparatus and method for recovering and recirculating optical-fiber coolant gas

A coolant, recycling technology, used in lighting and heating equipment, household refrigeration units, glass manufacturing equipment, etc., to solve problems such as increased concentrations of pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Various items of equipment, such as fittings, valves, mounting blocks, piping, wiring, etc., have been omitted to simplify the description. However, such conventional equipment and its use are known to those skilled in the art and can be used as desired. Furthermore, although the invention is described below in terms of recovering and recirculating coolant gas, the present invention can be used and adapted to many different recovery and / or recycling plants and processes.

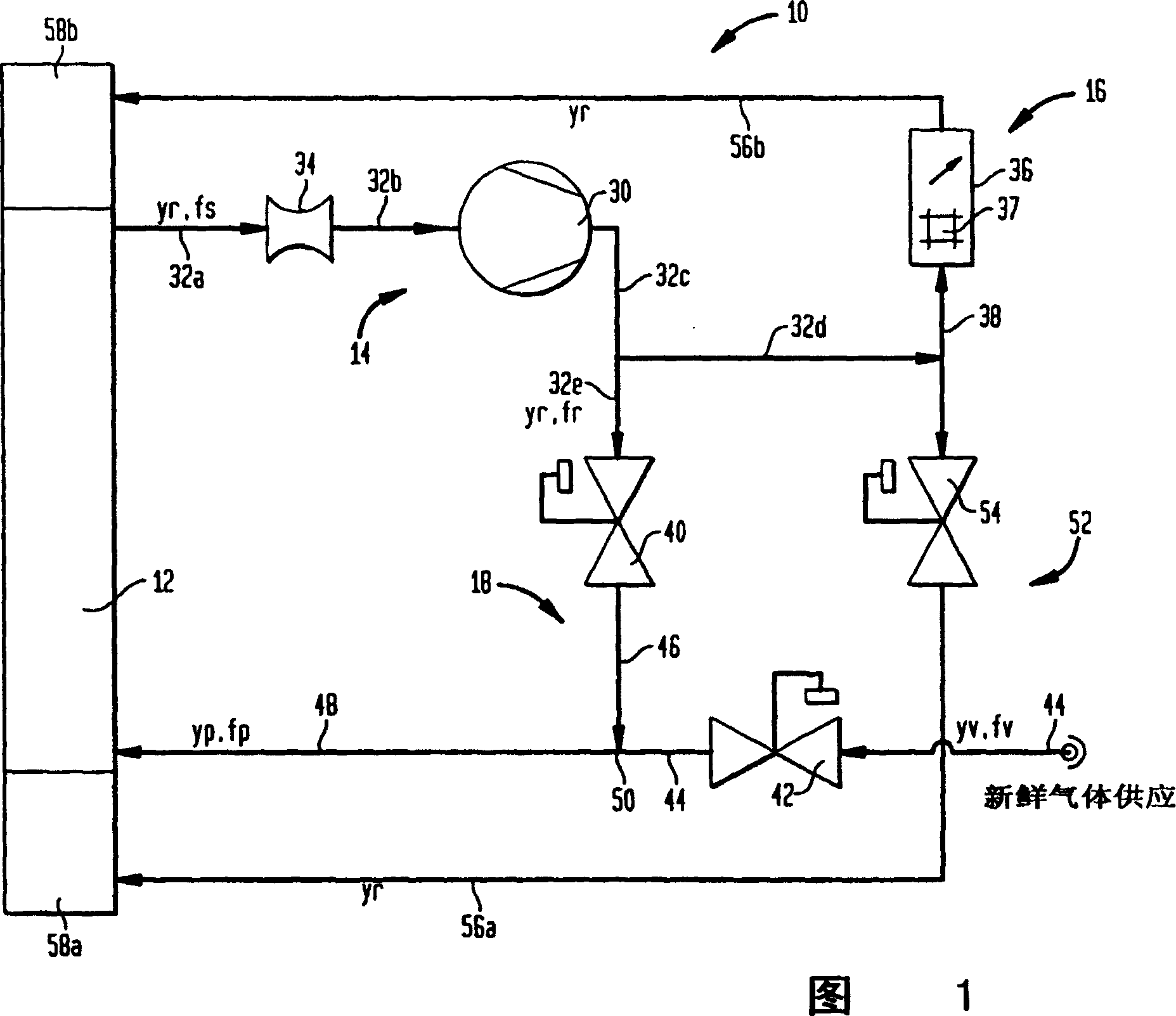

[0021] Referring to FIG. 1 , there is shown a system 10 for recovering and recirculating coolant gases such as helium, nitrogen, helium-nitrogen mixtures, helium-air mixtures, and the like. The system 10 includes a heat exchanger 12 , a coolant gas recovery section 14 , an analysis section 16 , and a coolant gas mixing section 18 operatively connected to each other.

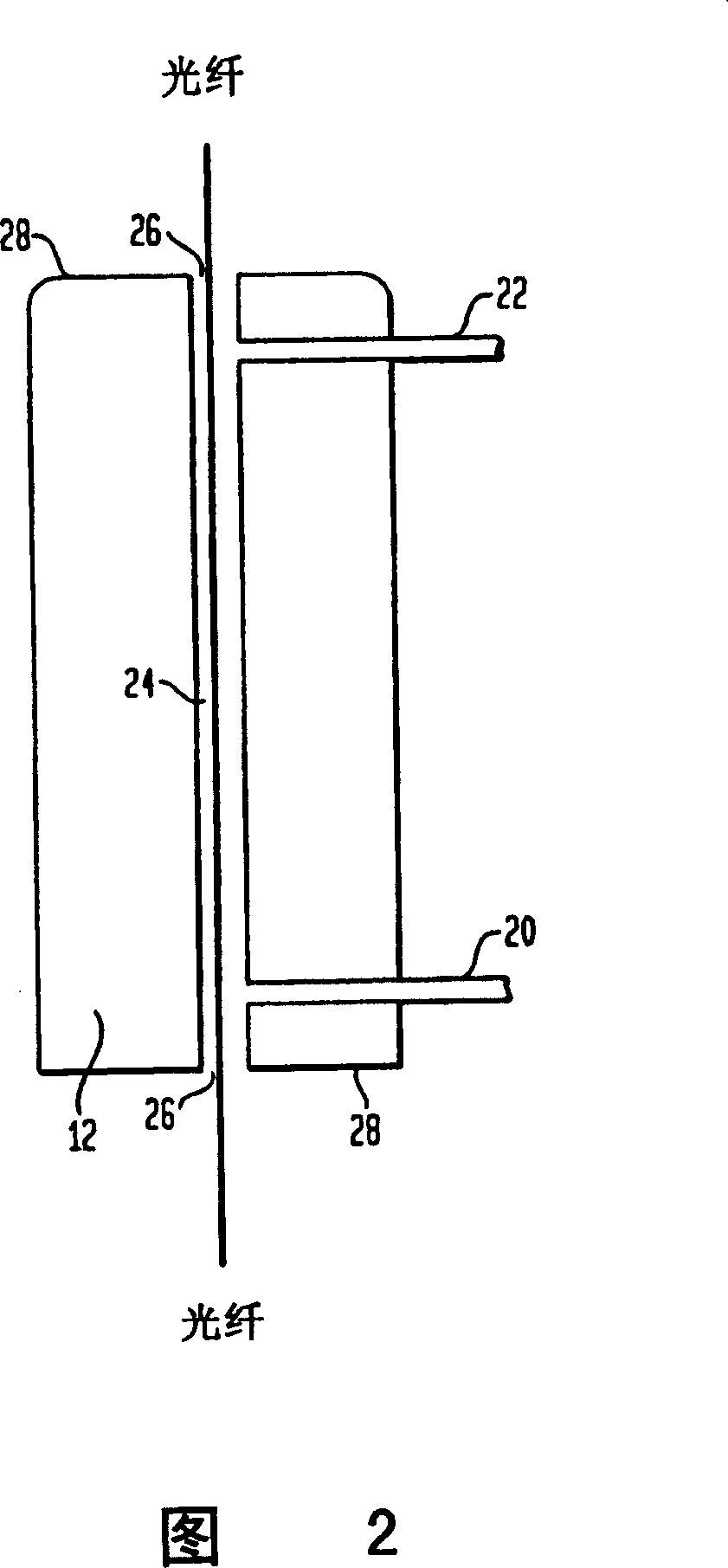

[0022] Heat exchanger 12, as shown in detail in FIG. heat exchanger or similar equipment). As shown in FIG. 2, the heat exchanger 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com