Multi-batch crystal circle attribute number revising method

A technology of attribute numbering and attribute modification, applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve the effect of saving the time of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

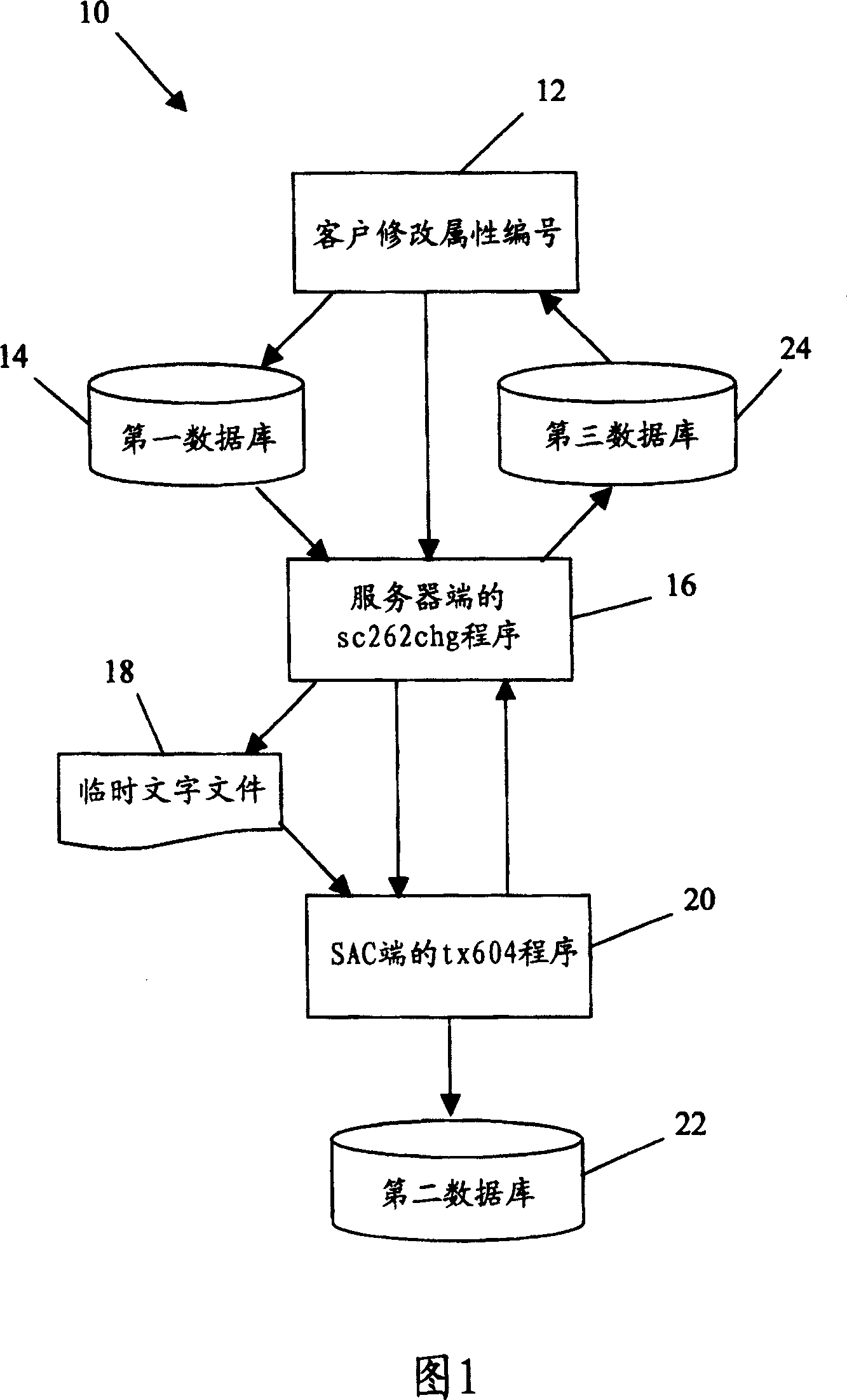

Embodiment Construction

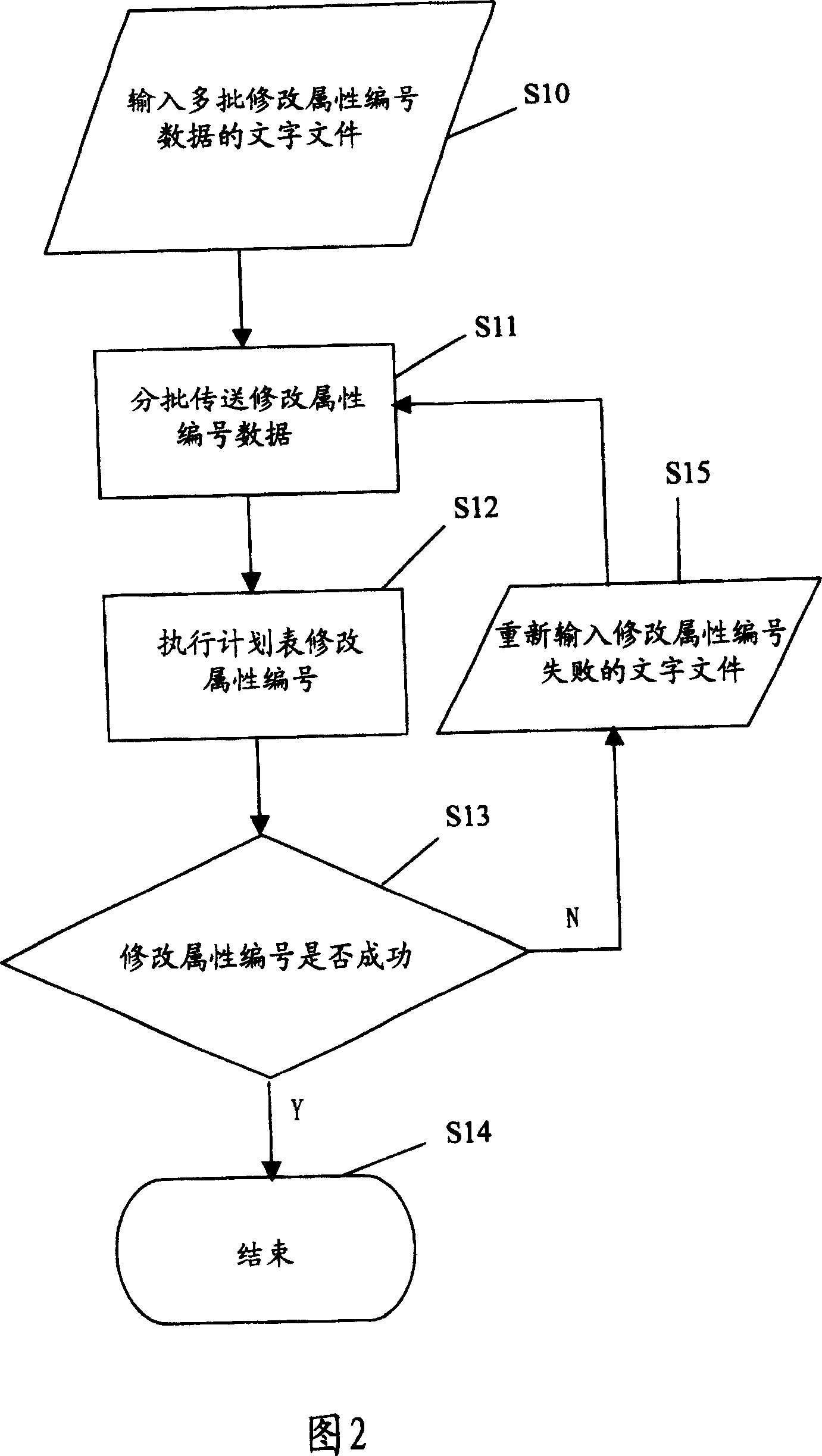

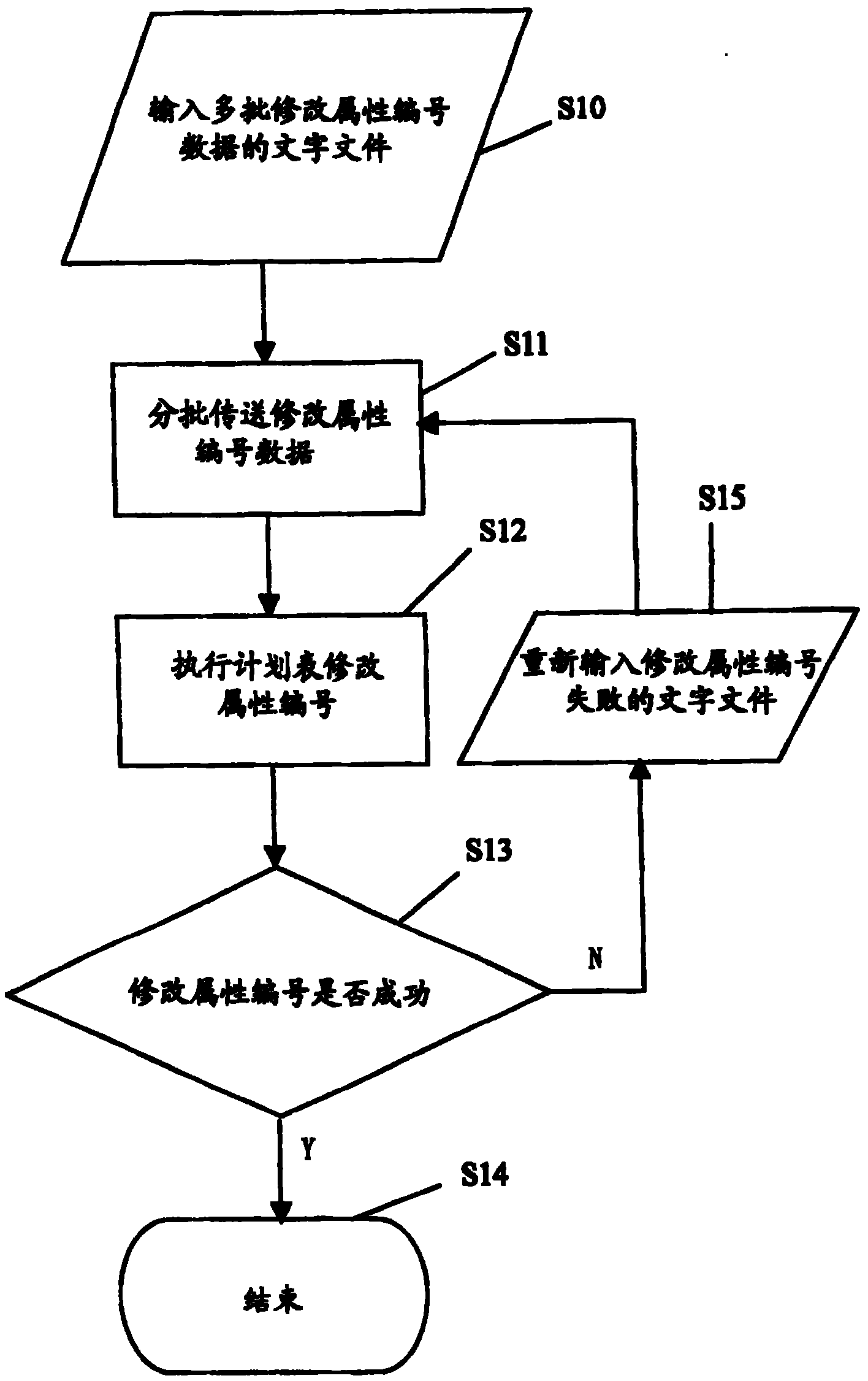

[0020] Fig. 2 is the flow chart of modifying attribute numbering of the present invention, at first step S10 imports the text file of many batches of modifying attribute numbering data, then step S11 transmits and revises attribute numbering data in batches, step S12 executes the schedule modification attribute numbering, then step S13 Determine whether the modification of the attribute number is successful, if yes, go to step S14, otherwise go to step S15. The step S14 ends, and after a reference time, the modified attribute number data is sent in batches in step S11 until there is no modified attribute number data. In step S15, the system automatically rewrites the text file whose attribute number fails to be modified, and then executes step S11 to transmit the modified attribute number data in batches. Utilizing this method can improve the known automation system, when modifying the attribute numbering method, only one data change can be written at a time, and it is impossi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap