Texturing machine

A texturing machine, crimping technology, applied in the direction of textiles and paper making, to achieve the effect of simplifying the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

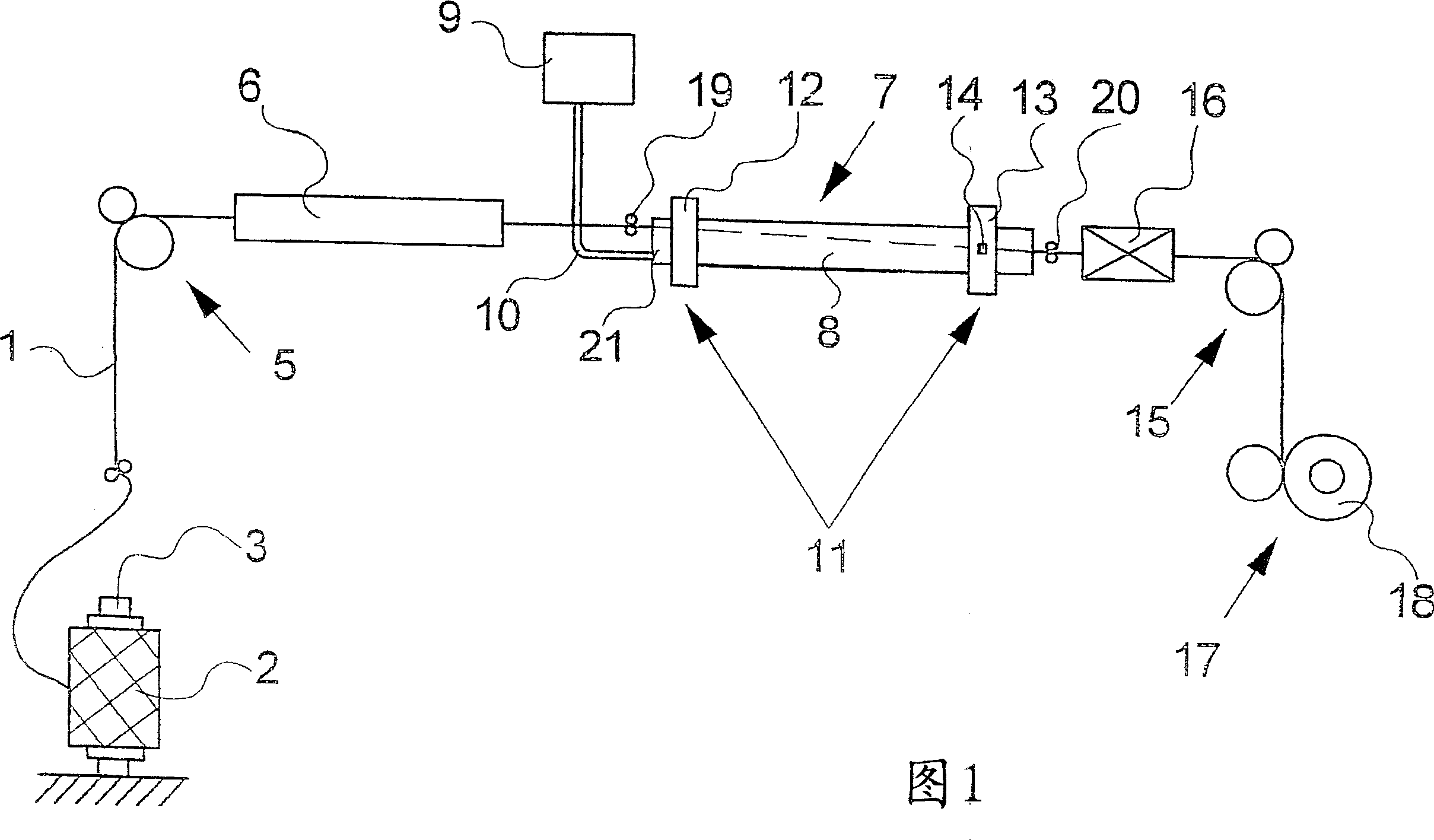

[0018] Figure 1 schematically shows the structure of a station in a crimp texturing machine. The crimp texturing machine has many stations, among which the multi-station processing unit is fixed on one or more stands. In order to crimp the filament 1, a station contains at least a first conveying device 5, a heating device 6, a cooling device 7, a false twister 16, a second conveying device 15 and a winding device 17, wherein The processing units are arranged in sequence to form a filament process. Here the filaments 1 are withdrawn from the feed bobbin 2 by the first conveying device 5 . Feed bobbins 2 are inserted on a mandrel 3 of the creel (not shown here). The first delivery device 5 guides the filament 1 into the so-called false twist zone, which extends as far as the false twister 16 . False twist is produced in the filament 1 by the false twister 16 , the false twist is traced back into the filament in the false twist zone and is then fixed in the heating device 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com