Inkjet printer head and inkjet printer

An inkjet print head and inkjet printer technology, applied in printing, inking devices, etc., can solve the problems of inkjet failure and image quality deterioration, and achieve the effect of preventing deformation and strengthening rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

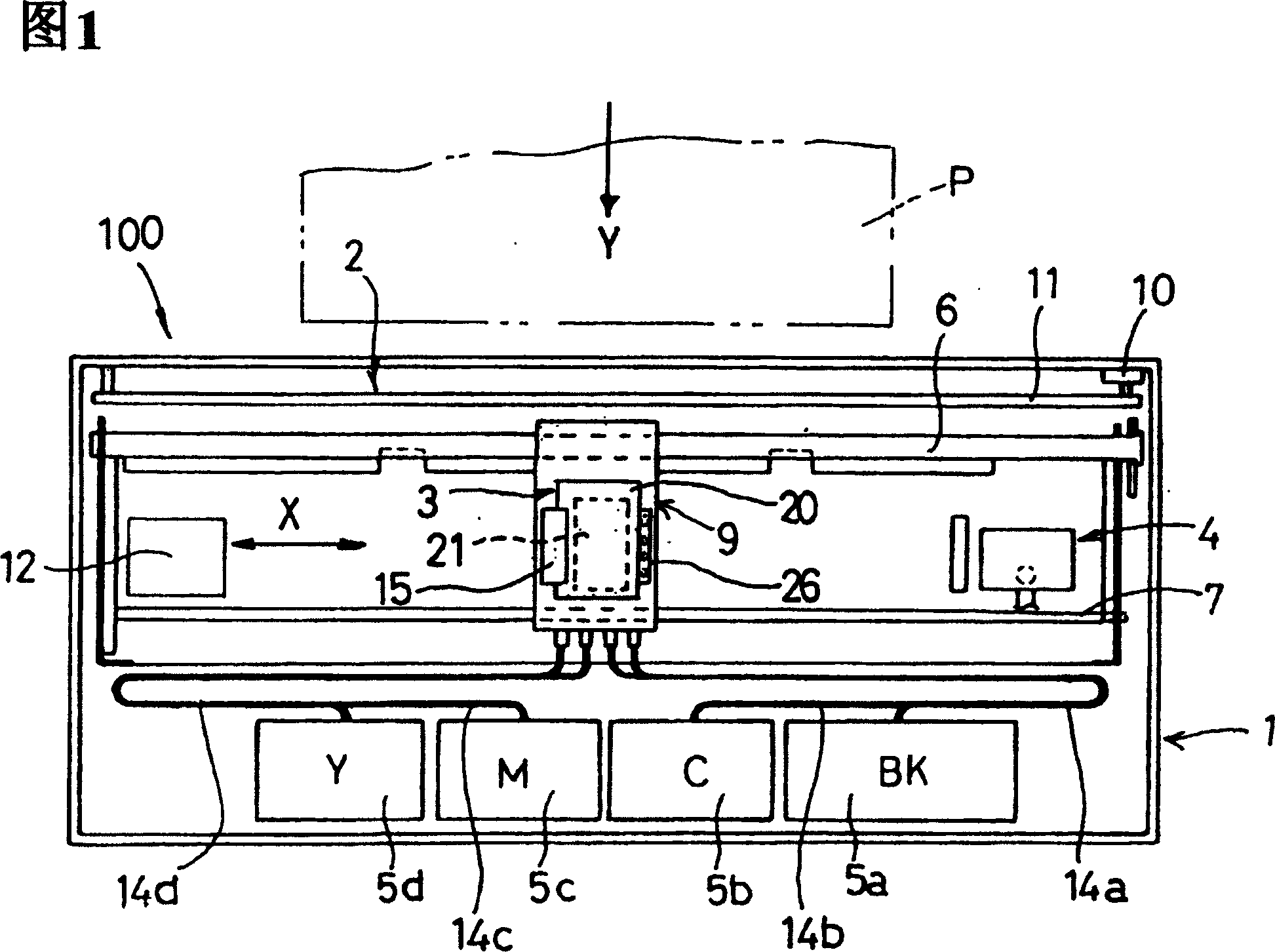

[0045] Preferred embodiments of the present invention are described below with reference to the accompanying drawings. Figure 1 is a top plan view of an inkjet printer 100 constructed in accordance with one embodiment of the present invention. The inkjet printer 100 comprises: a housing 1; a recording part 2 included in the housing 1; a recording head or a print head 3 included in the recording part 2, and the recording head or the print head 3 can be operated to eject ink droplets to a printing medium paper P to record or print an image on the paper P; a maintenance unit 4 that can be operated to maintain the print head 3; and four ink tanks 5 that respectively store inks of different colors to be supplied to the print head 3 , and the four ink containers 5 are detachably fixed to the housing 1 .

[0046] In order to perform a full-color image printing operation, the four ink tanks 5a, 5b, 5c, 5d store black ink (BK), cyan ink (C), yellow ink (Y) and magenta ink (M), respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com