Needle-bar travel regulating device

A technology for adjusting device and needle bar stroke, which is applied to the needle seat of sewing machine, textile and papermaking, sewing equipment, etc., which can solve the problems of excessive processing costs and achieve good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Embodiments of the present invention will be described in detail below with reference to the drawings.

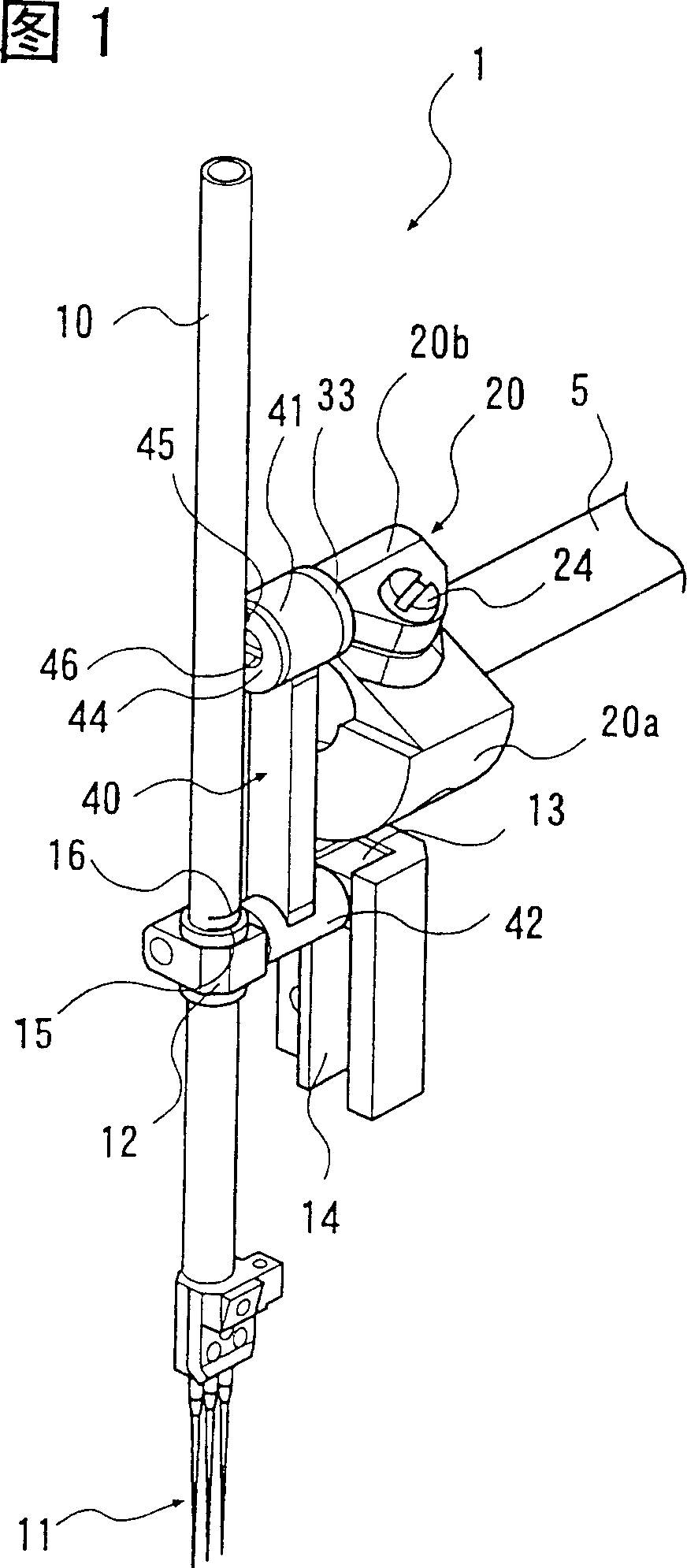

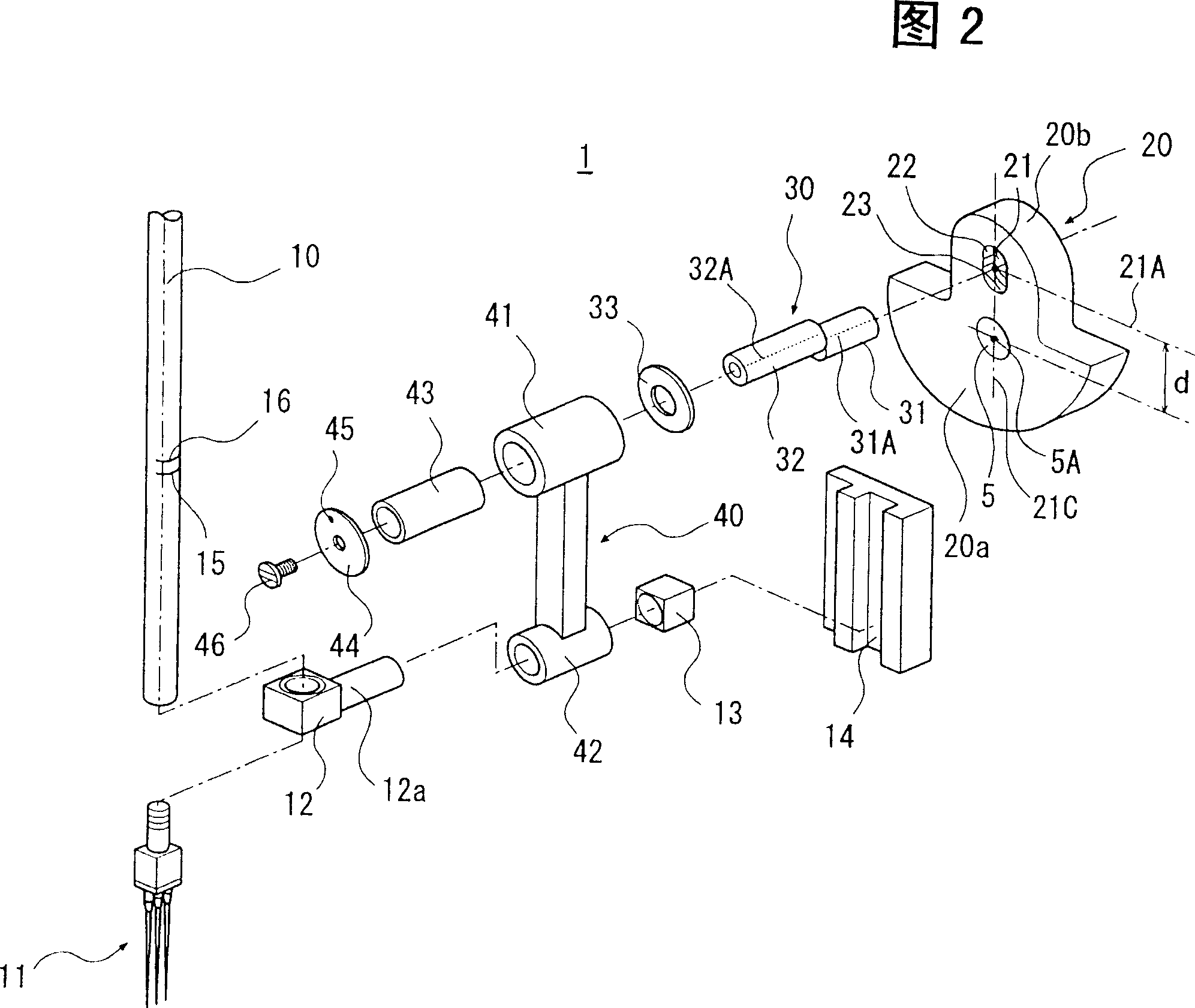

[0044] The needle bar stroke adjustment device 1 of the embodiment of the present invention is shown in Fig. 1 and Fig. 2, possesses: the crankshaft 20 that is fixed on the upper shaft 5; The eccentric pin 30 that one end is fixed on the crankshaft 20; A connecting rod 40 connected to the needle bar 10 at one end.

[0045] The upper shaft 5 is centered on the shaft center 5A shown in FIG. 2, and is driven to rotate around the shaft by a sewing machine motor not shown in the figure. A crankshaft 20 is fixed to the upper shaft 5 so as to be integrally rotatable.

[0046] The crankshaft 20 includes: a substantially semicircular counterweight 20a; and a crank arm 20b protruding substantially from the center of the circle of the counterweight 20a. Furthermore, in FIG. 2 , the illustrated crankshaft 20 is simplified.

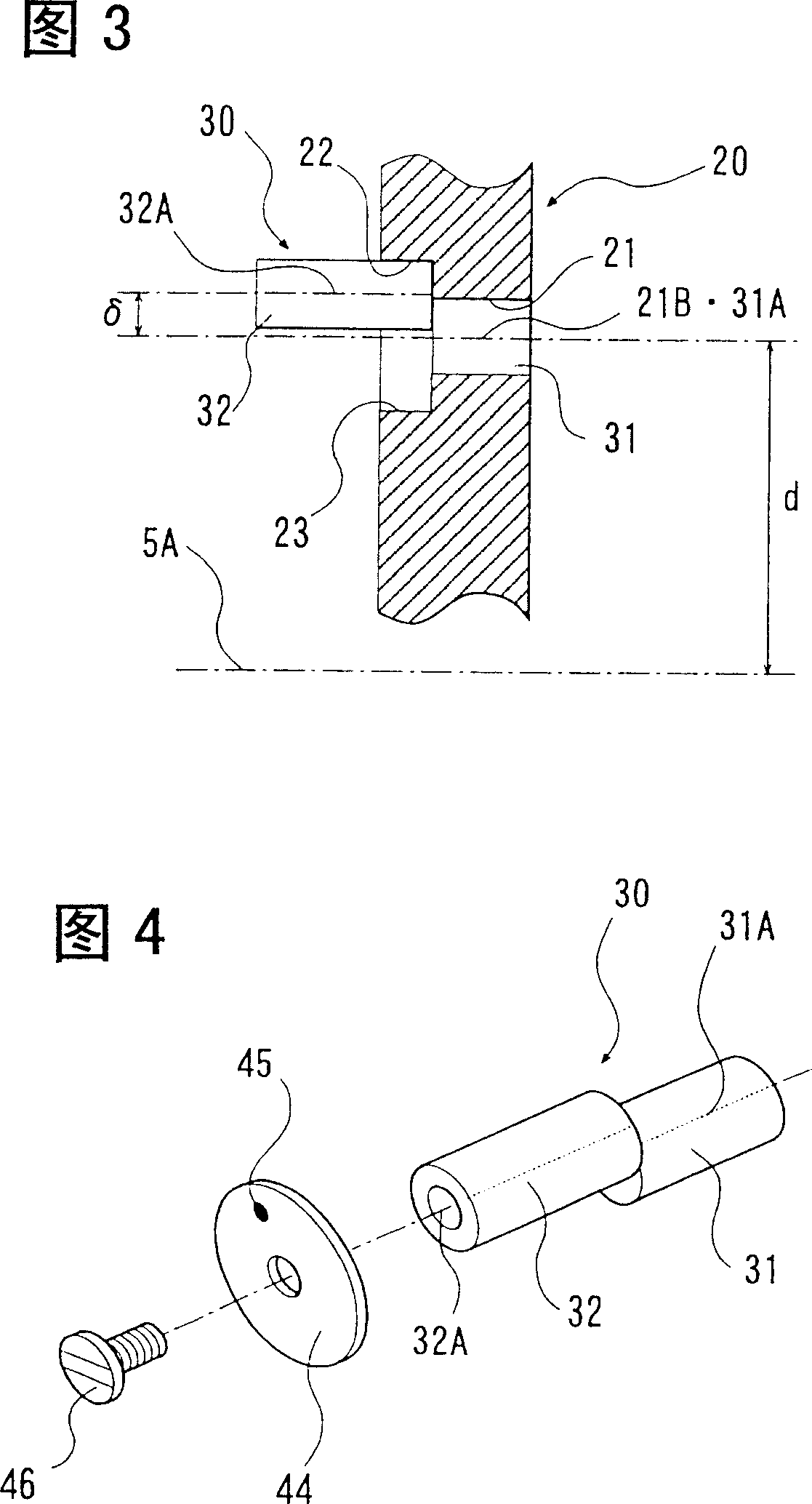

[0047] A mounting hole 21 for fitting the shaft por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com