Fragile material cutter, line drawer therewith and method therefor

A technology of brittle materials and brittle material substrates, which is applied in the field of glass cutting knives, can solve the problems that the part of the cutting starting point cannot be cut correctly, the glass has missing corners, etc., and achieve the effect of eliminating the empty cutting phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

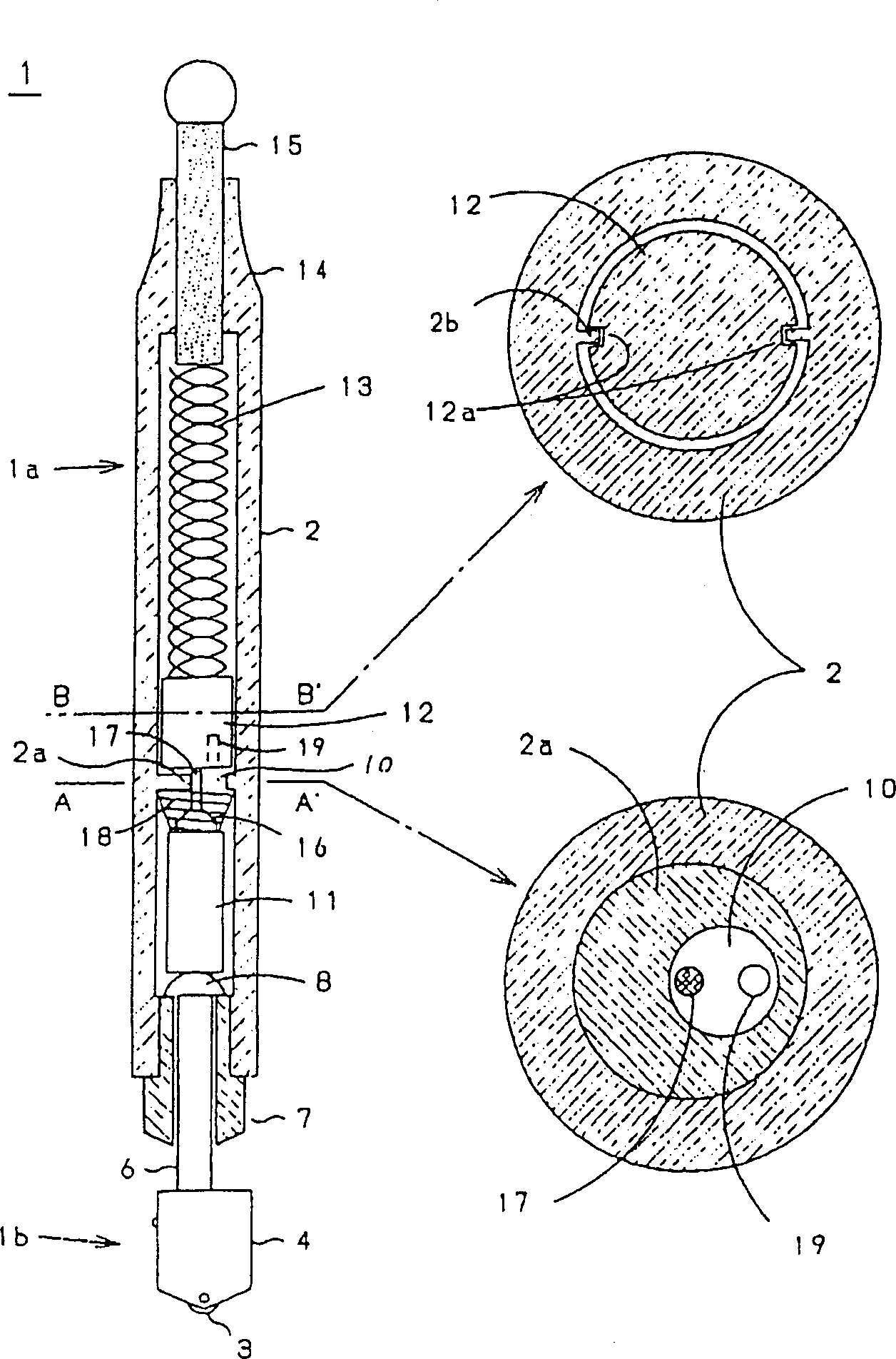

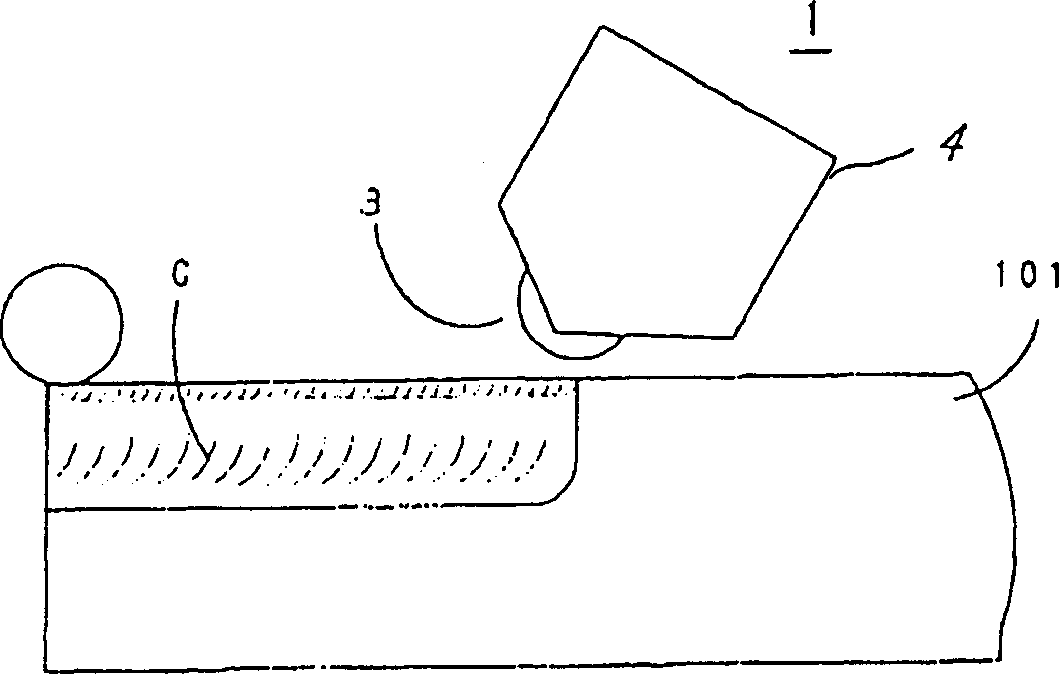

[0050] figure 1 It shows the cross-sectional structure of the glass cutter 1 which concerns on the 1st Example of this invention. The glass cutter 1 is composed of the following two parts:

[0051] 1. The body part 1a constituted by the cylinder body 2;

[0052] 2. The cutter head 1b is rotatably attached to the holder 4 with the cutter wheel 3 made of, for example, a tungsten alloy.

[0053] The shaft 6 provided on the holding part 4 passes through the shaft supporting part 7 installed on the lower end of the cylinder body 2, so that the cutter head 1b can slide in the up and down direction. The upper end of the shaft 6 has a rivet-shaped head 8 to prevent the shaft 6 from falling off from the shaft supporting portion 7 .

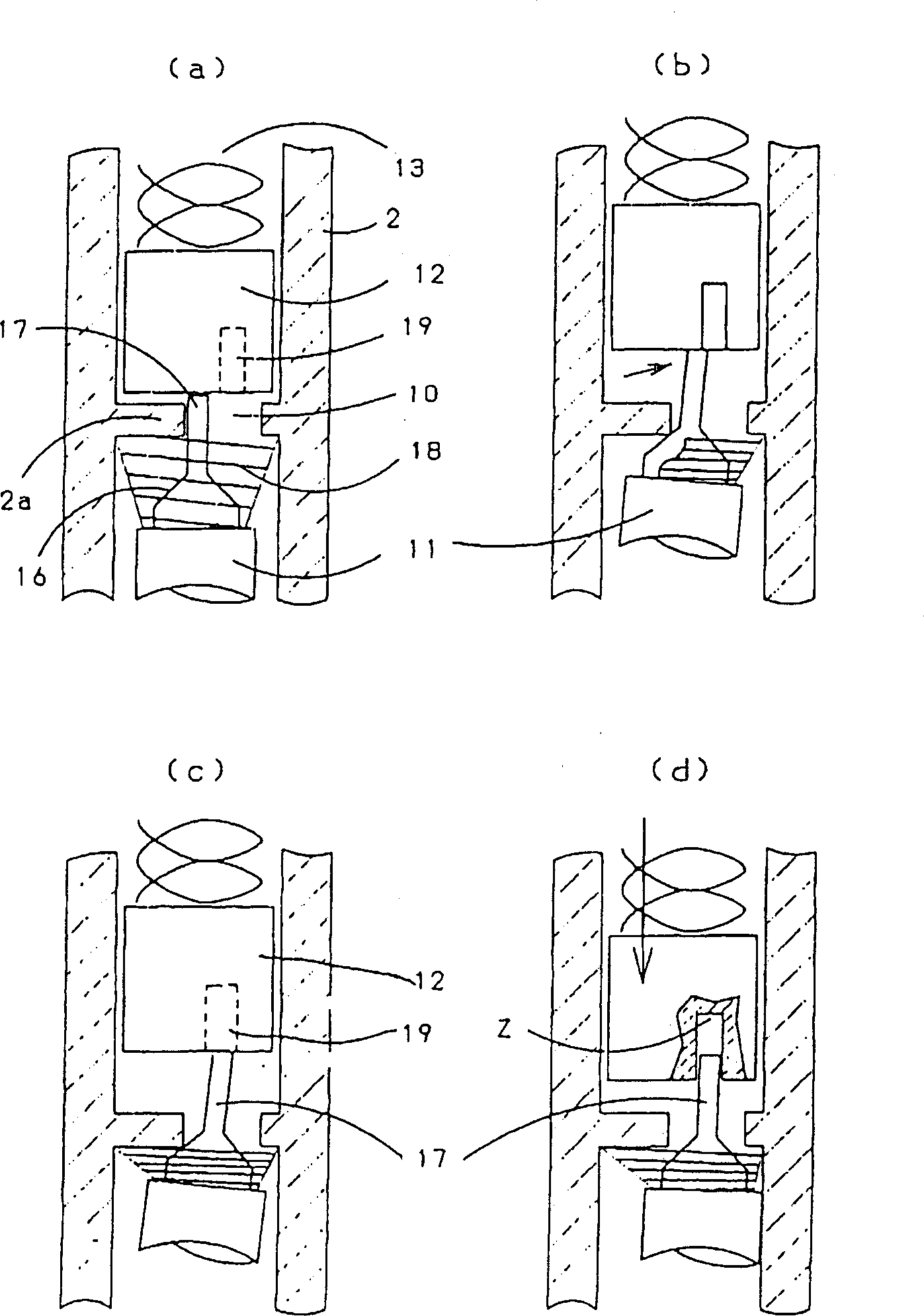

[0054] In addition, as described later in the present invention, when scribing, the glass cutting knife is used to push the shaft 6 and the cutter head 1b upward into a predetermined amount, and exerts an impact force on the cutter head 1b, so the shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com