Method for cutting sheet-metal plates into sheet-method strips and a cutting device for carrying out the same

A technology of metal plates and metal strips, which is applied in the field of devices for transporting metal strips and devices for shearing metal plates, which can solve the problems of increased space requirements, stable metal plates, and expensive positioning beds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

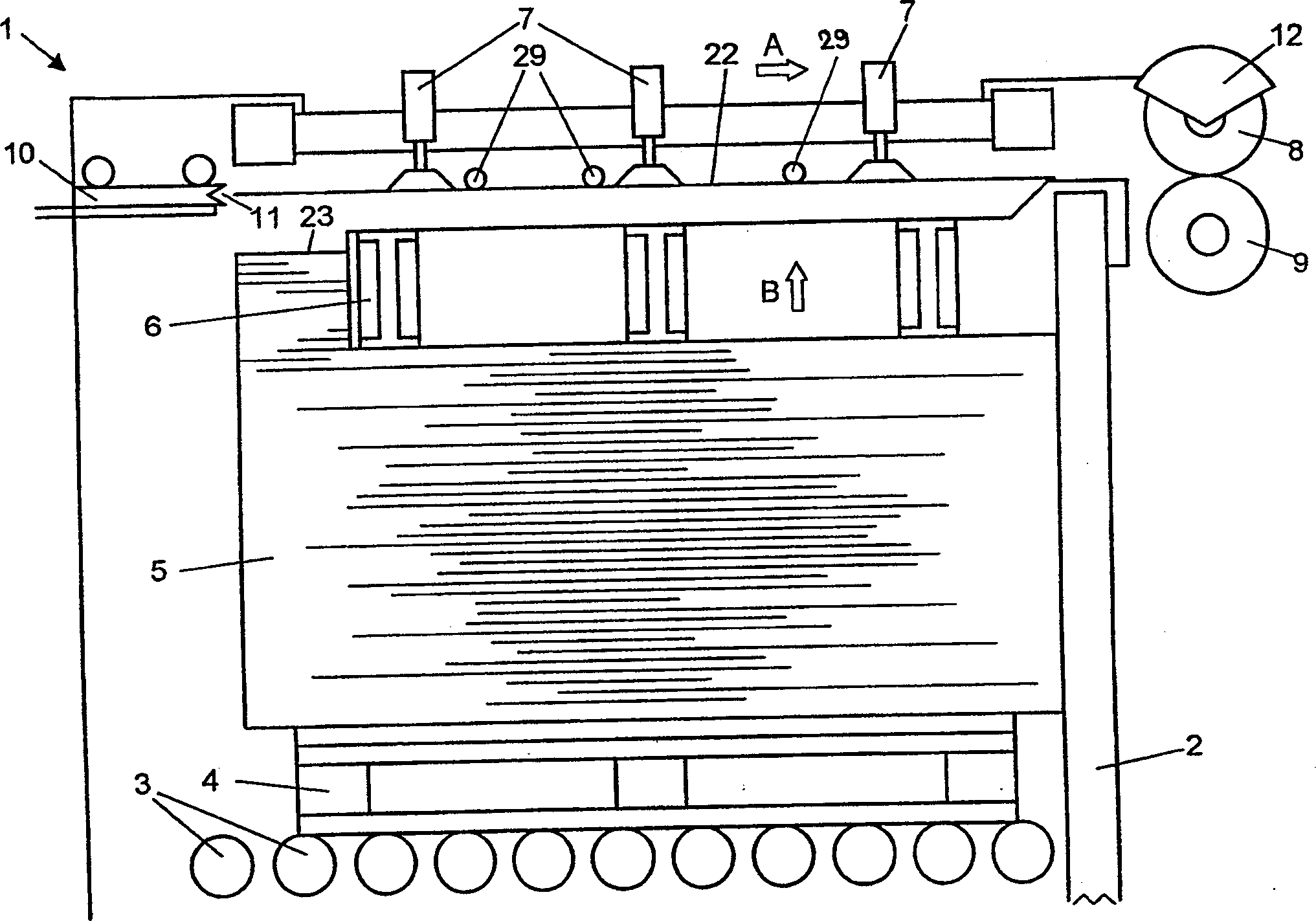

[0026] figure 1 A side view of a shearing device 1 is shown, with parts of the frame 2 omitted in order to show the shearing device more clearly. The device has a receiving device 3 on which a sheet metal stack 5 is received in the device 1 , the sheet metal stack 5 resting on a base plate 4 . Here, the sheet metal stack can be clamped by side guides and expansion magnets 6 in the area where the sheet metal is removed from the stack. Above the stack are several means 7 for removing metal sheets from the stack, which are able to release and lift the uppermost sheet metal in the stack from the stack, for example by means of the illustrated pneumatic suction cups. Such removal of metal sheets from a stack is well known and therefore will not be further described here. figure 1 Also shown in is a shearing unit 12, which in the shown case consists of a disc shear with a plurality of circular blade pairs 8 and 9. Such disc shears are also known and need not be described in detail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com