Integrated optical switch array

An optical switch and array technology, applied in optics, light guides, optical components, etc., can solve the problems of low switch packaging efficiency and non-unique optical path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

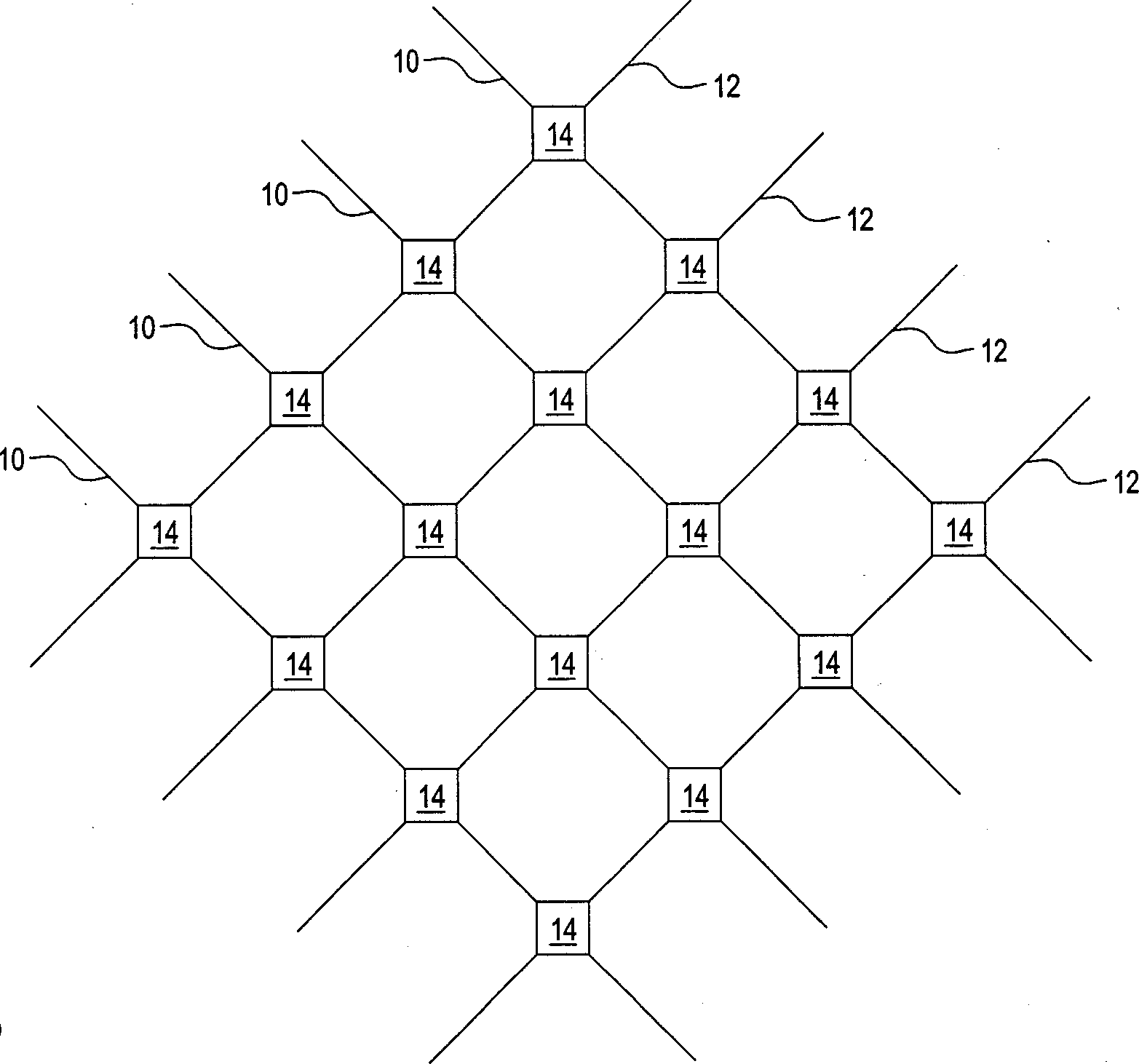

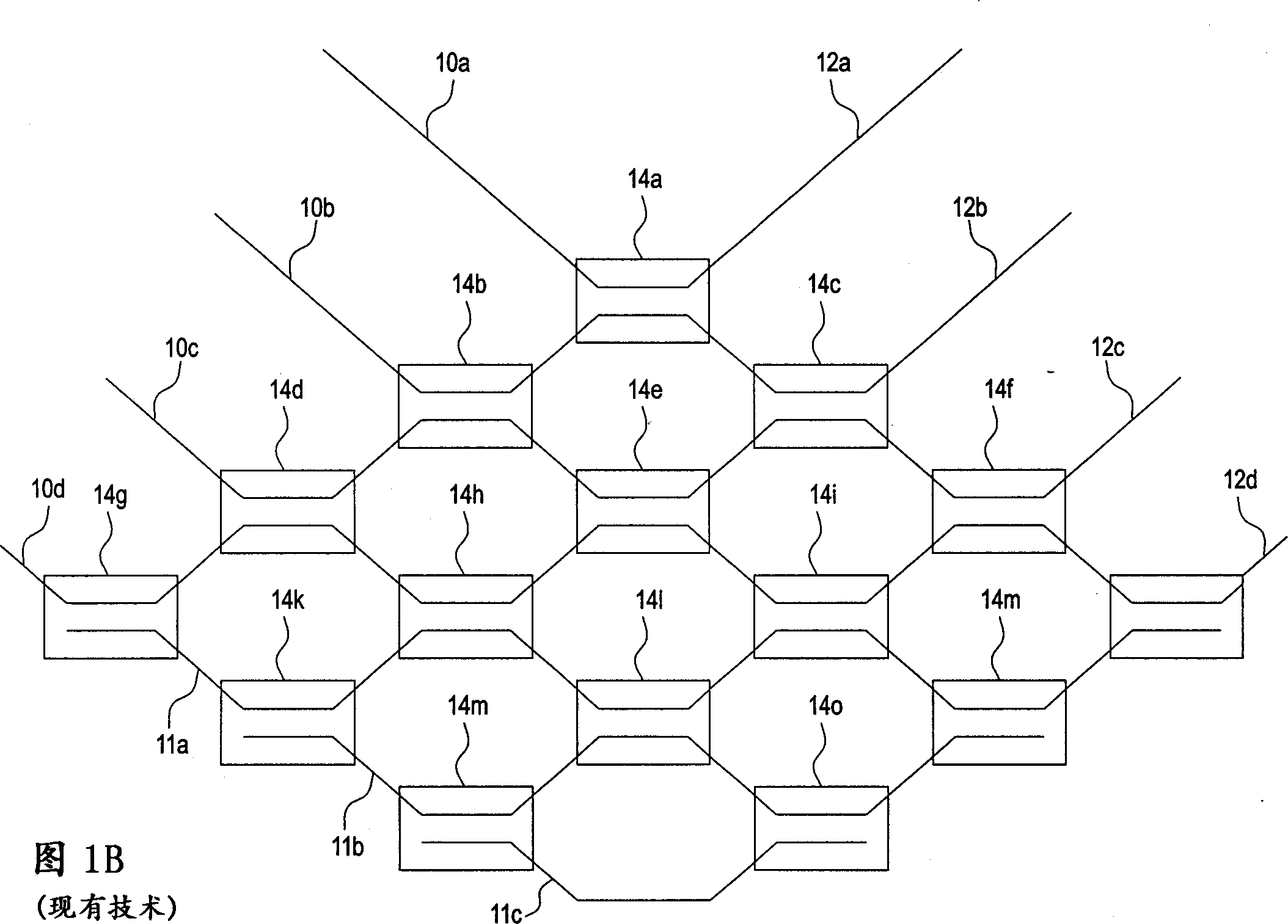

[0034] The geometry of the integrated optical switch array of the present invention allows it to be manufactured more compactly than known optical switch arrays.

[0035] The working principle of the optical switch array of the present invention can be fully understood with reference to the drawings and descriptions thereof.

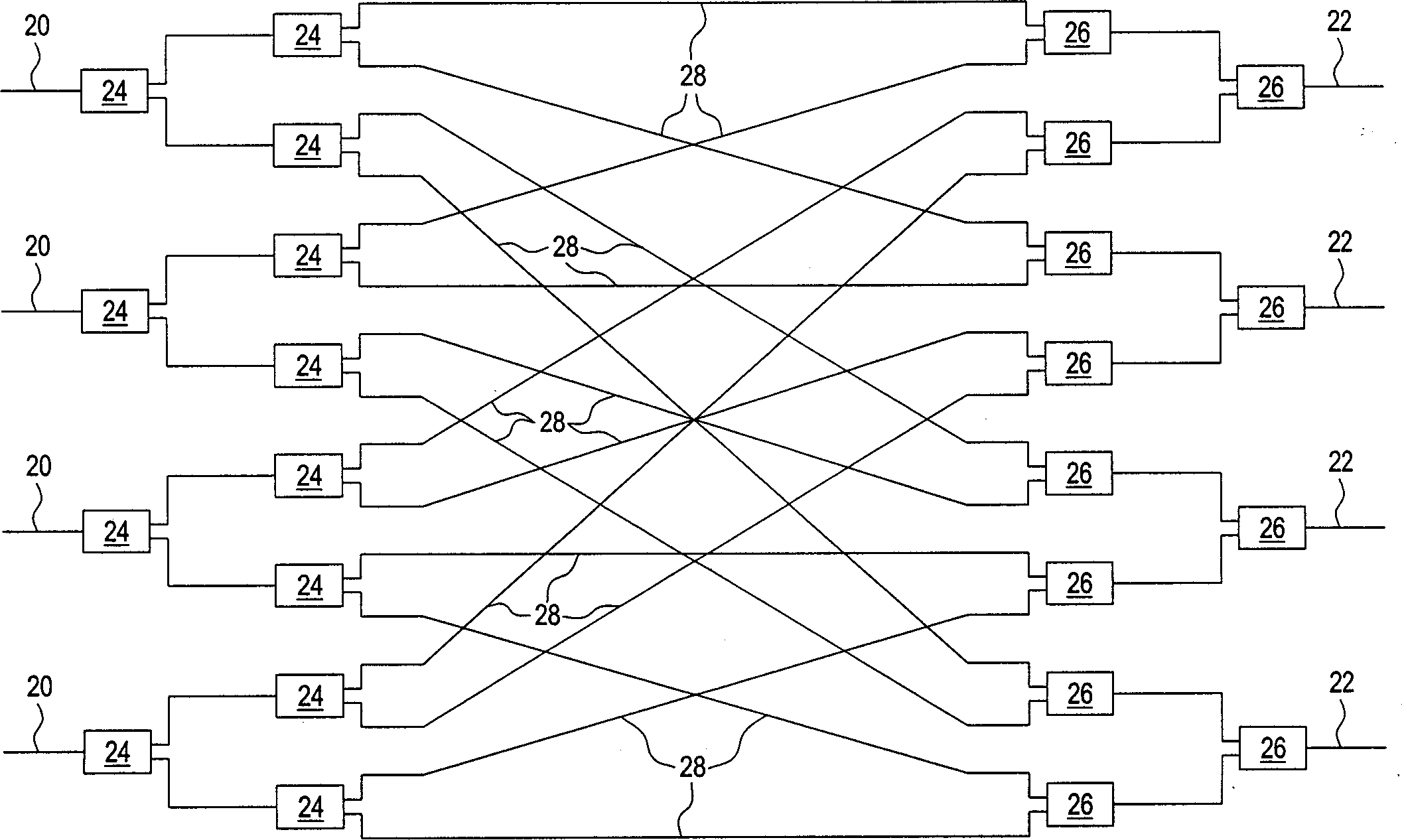

[0036] Referring now to the drawings, FIG. 5A is a schematic diagram of a switch array of the present invention for coupling input waveguides 140a, 140b, 140c and 140d to output waveguides 142a, 142b, 142c and 142d. Input waveguide 140a, coupled to output waveguide 142a with 1x2 switch 144aa through intermediate waveguide 148aa and passive y-tangle combiner 146aa, coupled to output waveguide 142a with 1x2 switch 144ab through intermediate waveguide 148ab and passive y-tap combiner 146ab to Output waveguide 142b, coupled to output waveguide 142c with 1x2 switch 144ac via intermediate waveguide 148ac and passive y-junction combiner 146ac, and coupled to O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com