Sewing machine

A sewing machine and needle technology, applied in the field of sewing machines, can solve problems such as the excessively long end of the upper thread, and achieve the effects of good operability and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

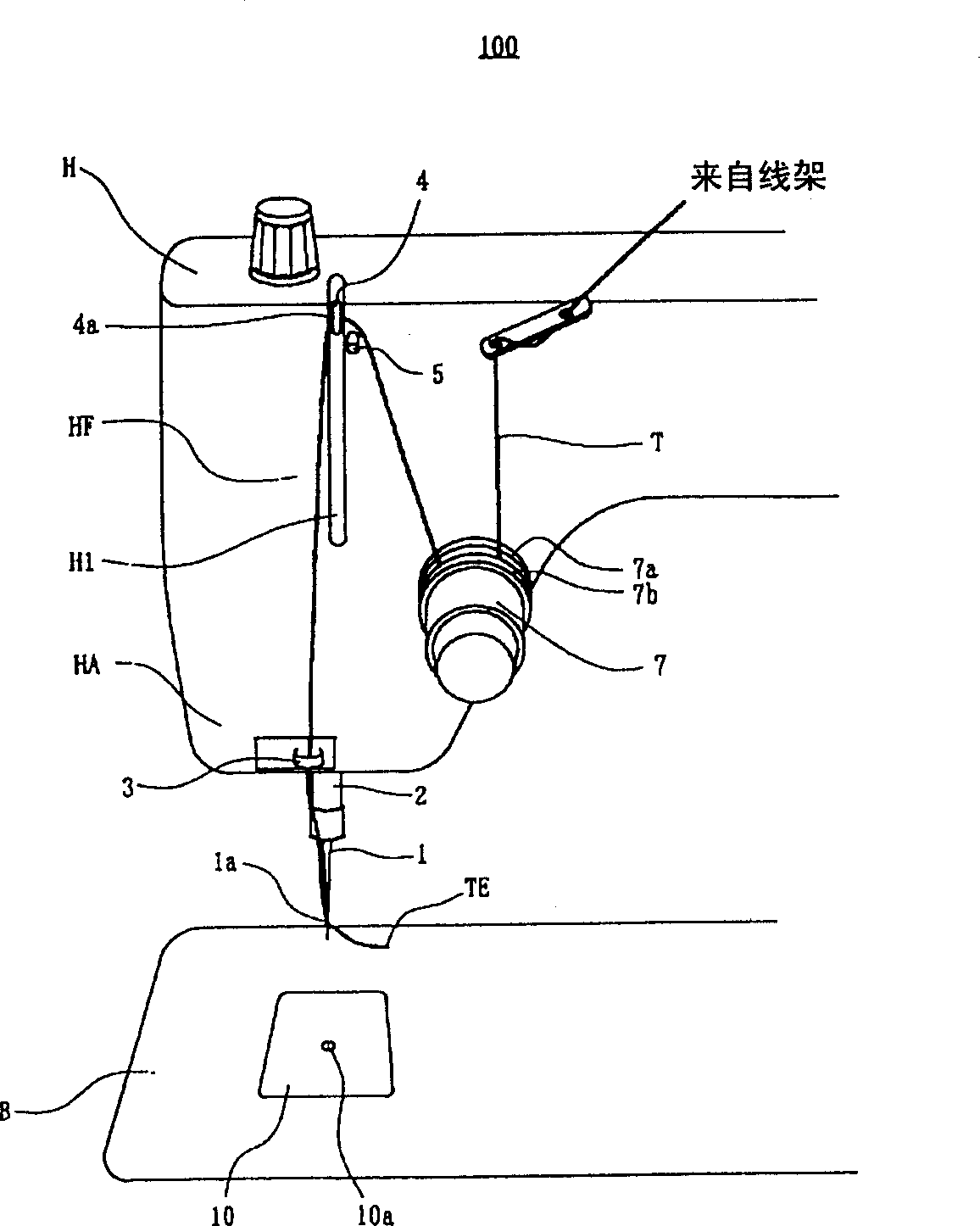

[0039] Such as figure 1 As shown, the sewing machine 100 of the present invention has a machine table B on which clothes are sewn, and a sewing machine head H facing the machine table B and arranged above the machine table, and has the following structure.

[0040] The needle 1 is fixed on the needle bar 2 which moves up and down. The needle bar 2 is linked with the upper shaft (not shown) of the sewing machine arranged on the sewing machine head H, and there is a needle thread T under the needle 1. The pinhole 1a. The thread loop 3 provided on the jaw portion HA protruding downward from the sewing machine head H guides the upper thread T to the needle 1 .

[0041] On the front HF of the sewing machine head H, there are formed on the top of the wire loop 3 and figure 1 Vertical slot H1 on the right. The thread take-up lever 4 has its front end protruding from the long hole H1 to the outside of the sewing machine head H, and is linked with the upper shaft of the sewing machi...

Embodiment 2

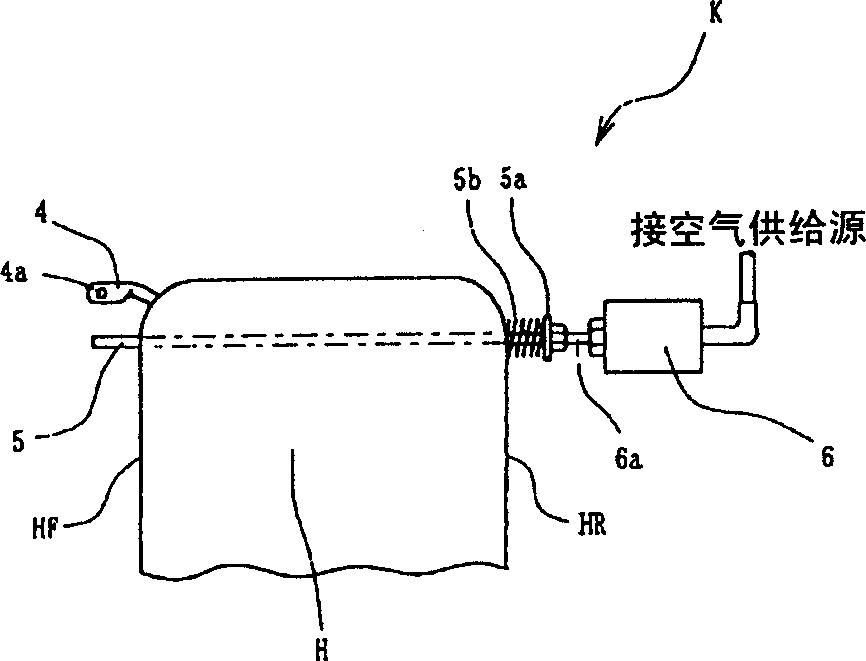

[0072] refer to Image 6 Example 2 will be described. Embodiment 2 is only different in the setting position of the line-reliance stop mechanism K, and the other structures are the same as Embodiment 1. The specific structure is as Image 6 As shown, the thread leaning stop lever 5 is arranged on the side of the needle opposite to the thread stand relative to the long groove H1, and is located approximately near the center of the long groove H1 in the vertical direction.

[0073] The setting position of the line stop lever 5, such as Image 6 As shown, when the hook tip 11a of the thread shuttle 11 is hung on the thread loop L, the thread take-up lever 4 is located at a slightly lower position in the vertical direction, and at the same time, when the thread leaning stop lever 5 is in the entry state, its front end is located at Entry position directly below the upper thread T hanging on the thread take-up lever 4.

[0074] In this way, according to this structure, after th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com