Wiring base plate, display device, semiconductor chip and electronic machine

A technology for wiring substrates and display devices, applied to semiconductor devices, semiconductor/solid-state device components, circuit devices, etc., can solve problems such as failure to maintain wiring quality and damage to metal wirings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

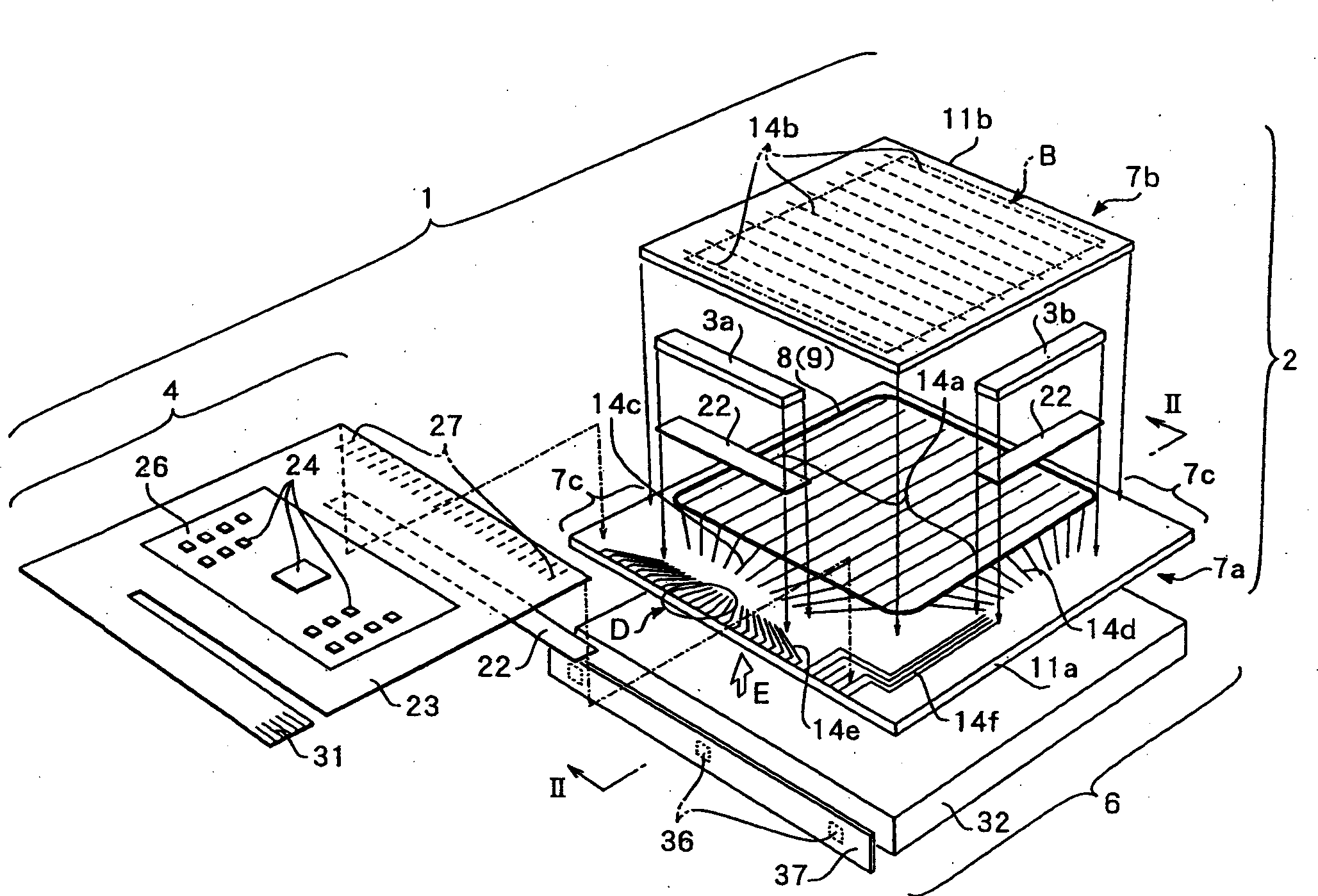

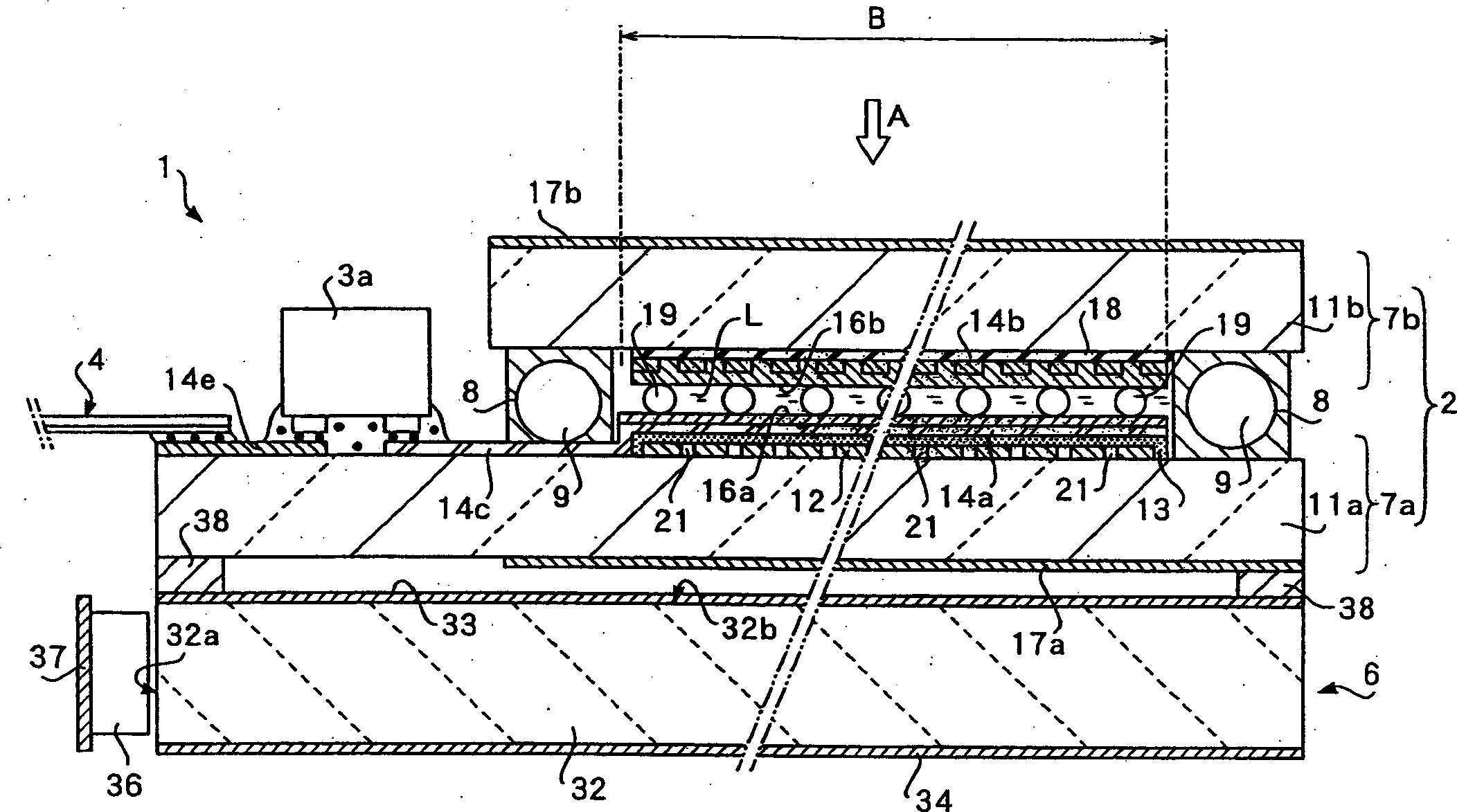

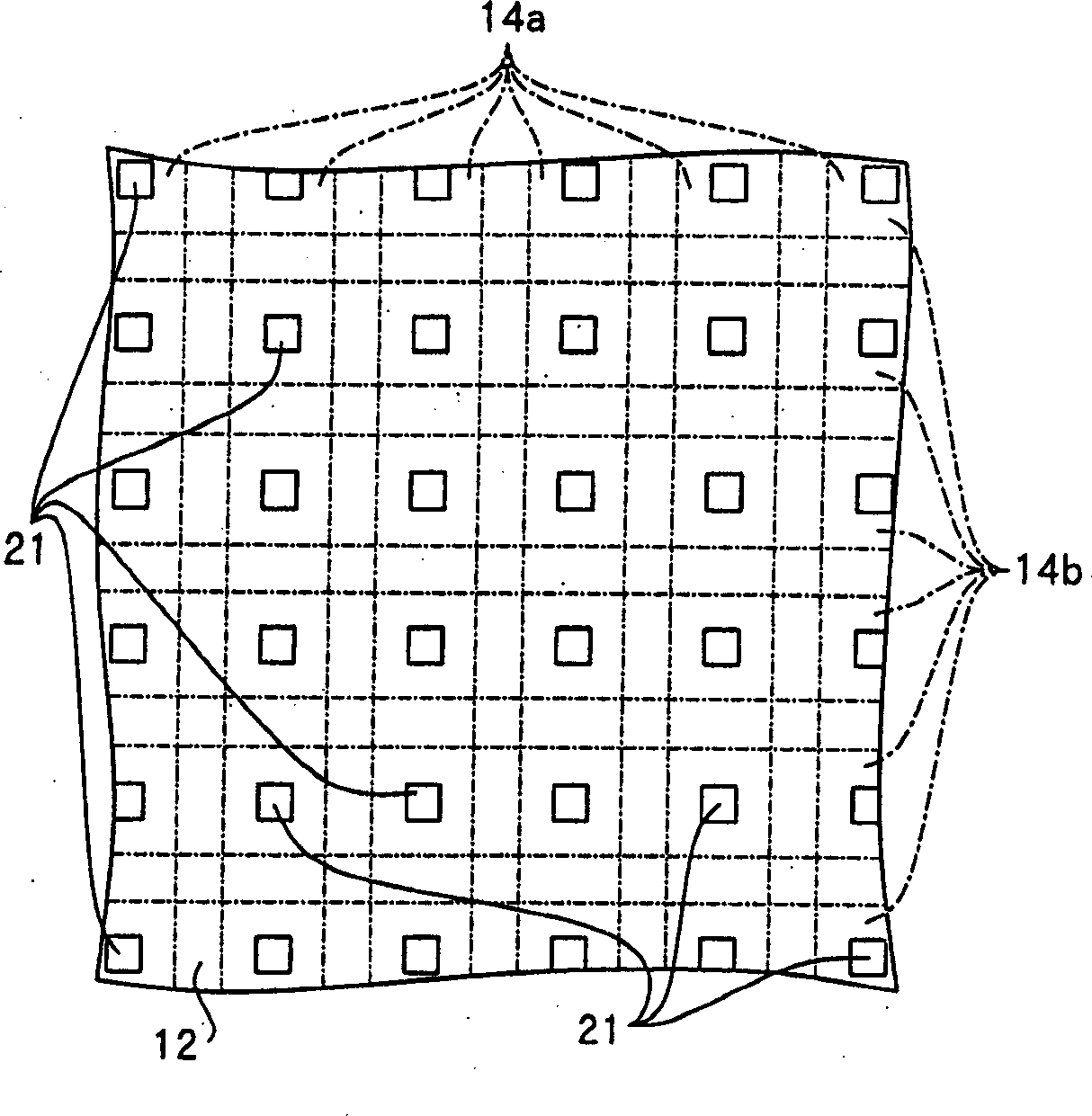

[0056] figure 1 An example in which the wiring board of the present invention is applied to a liquid crystal device, which is an example of a display device, is shown. In addition, when distinguishing liquid crystal devices according to driving methods, there are simple matrix and active matrix driving methods, but figure 1 The illustrated liquid crystal device is a simple matrix liquid crystal device. In addition, when classifying liquid crystal devices according to the method of supplying light, various methods such as reflective type, transmissive type, and transflective type can be considered, but figure 1 The illustrated liquid crystal device is a transflective liquid crystal device.

[0057] The reflective type is a liquid crystal device having a structure in which external light such as sunlight or indoor light is reflected on the back side of the liquid crystal layer, and the reflected light is used as a light source. In addition, the so-called transmissive type ...

no. 2 Embodiment

[0093] Figure 5 show Figure 4 A modified example of the metal wiring shown. related Figure 5 The illustrated plurality of metal wirings 14e is compatible with Figure 4 The illustrated embodiment is the same, that is, different voltages V1 to V4 are applied, and the protective wiring 29 made of conductive oxide, that is, ITO, is interposed between the anode-side metal wiring 14e to which a high voltage is applied and the anode-side metal wiring 14e to which a relatively low voltage is applied. It is arranged between the cathode side metal wirings 14e.

[0094] Figure 5 The present embodiment shown with Figure 4 The illustrated embodiment differs in that the ITO is removed from above the metal wiring 14e. In this way, even when ITO is not laminated on the metal wiring 14e, it is possible to prevent corrosion of the metal wiring on the anode side.

no. 3 Embodiment

[0096] Image 6 show Figure 4 Another modification of the metal wiring shown. related Image 6 The illustrated plurality of metal wirings 14e is compatible with Figure 4 The illustrated embodiment is the same, that is, different voltages V1 to V4 are applied, and the protective wiring 29 made of conductive oxide to ITO is interposed between the anode side metal wiring 14e to which a high voltage is applied and the cathode side to which a relatively low voltage is applied. The metal wirings 14e are arranged between each other, and the same ITO as the protective wiring 29 is laminated and covered on the metal wirings 14e, and the like.

[0097] Image 6 The present embodiment shown with Figure 4 The difference of the illustrated embodiment is that the connection between the protective wiring 29 and the ITO capping layer 41 on the metal wiring 14e is released, and the protective layer 29 is placed in a potential-free state. In this way, even when the protective wiring 29...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com