Heat exchanger assembling structure for split air conditioner

A technology of heat exchanger and assembly structure, which is applied in the field of assembly structure of split-type air conditioner heat exchangers, can solve problems affecting assembly work efficiency, etc., and achieve simple and fast installation of heat exchangers, prevention of cold air leakage, and easy assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing, the implementation of the present invention is described as follows:

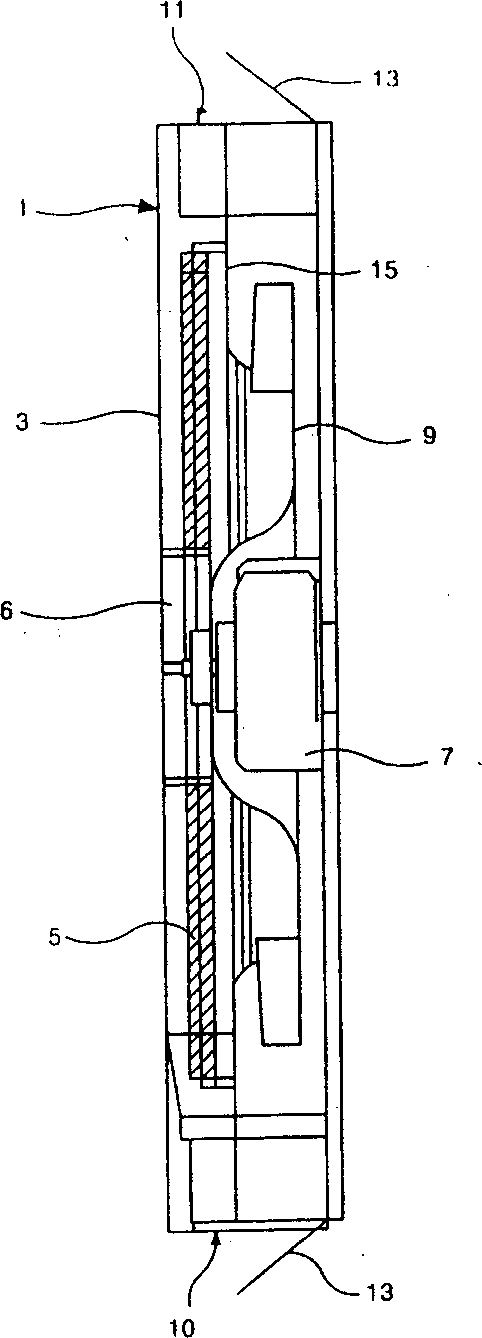

[0037] figure 1 The description has been described in detail in "Background Technology", so it is omitted here.

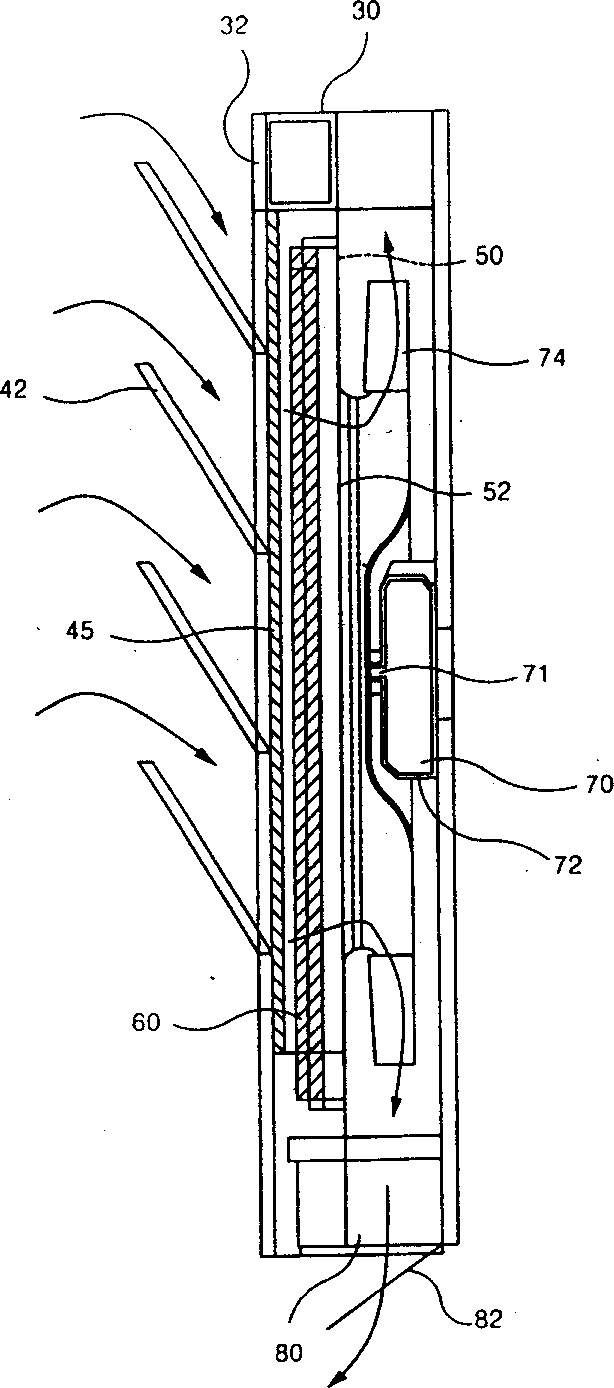

[0038] exist figure 2 In the following, the internal structure of the split-type air conditioner of the present invention adopting the frame structure will be described first.

[0039] The shell (30) constitutes the appearance of the indoor unit, and the shell (30) is a flat hexahedron. And above-mentioned housing (30) front part is provided with front baffle (32) to close the space that forms in the housing.

[0040] The air inlet (40) plays the role of sucking the outside air that needs to be adjusted into the interior of the indoor unit. Such air inlet (40) front is provided with several air intake vanes (42), and air intake vane (42) is located on the front baffle plate with left and right elongated shape, configures several up and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com