Industrial press safety system

A technology for safety systems, stamping machines, applied in the field of safety systems, which can solve problems such as extended delays, interruptions and errors, single beams or safety light curtains not working

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

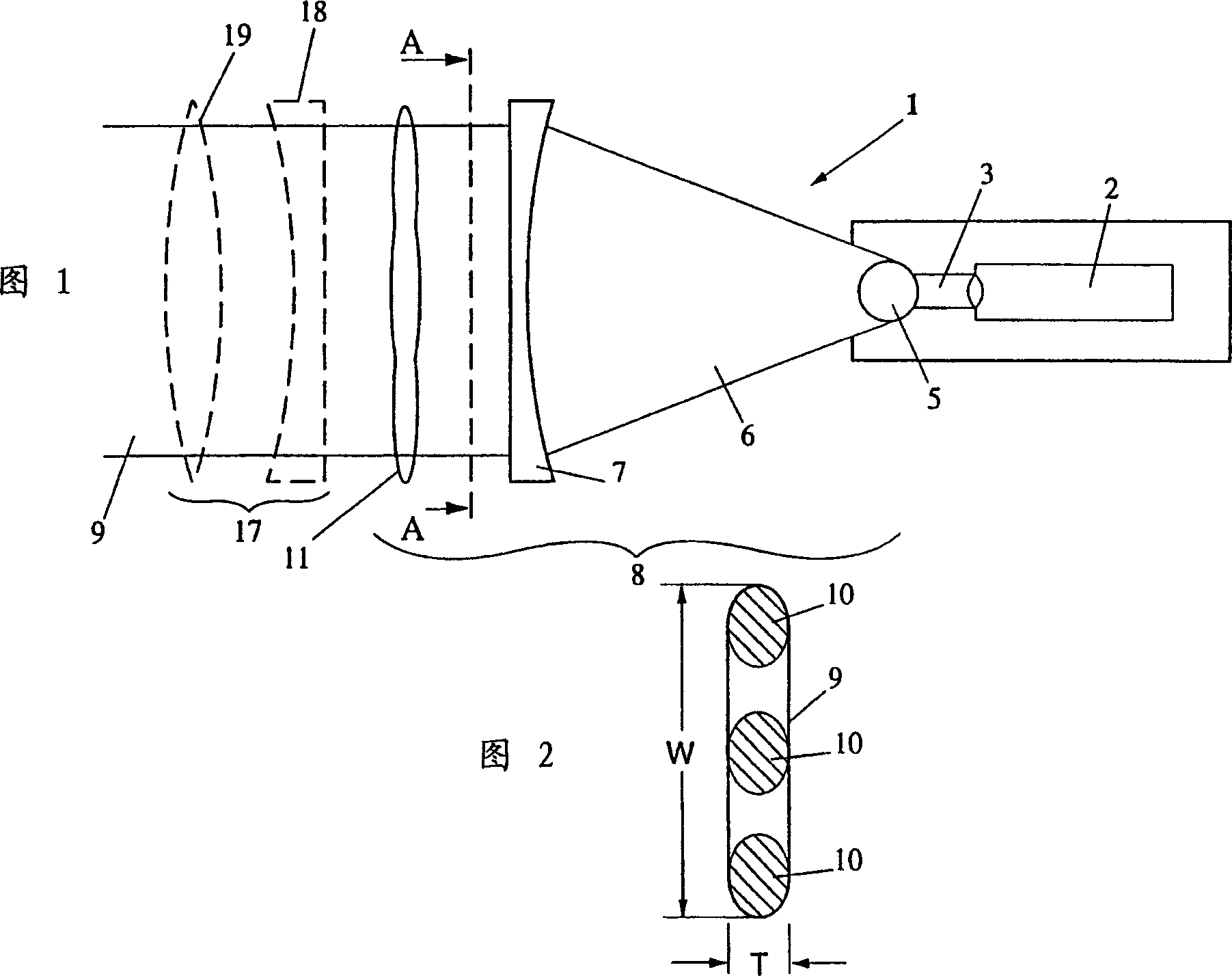

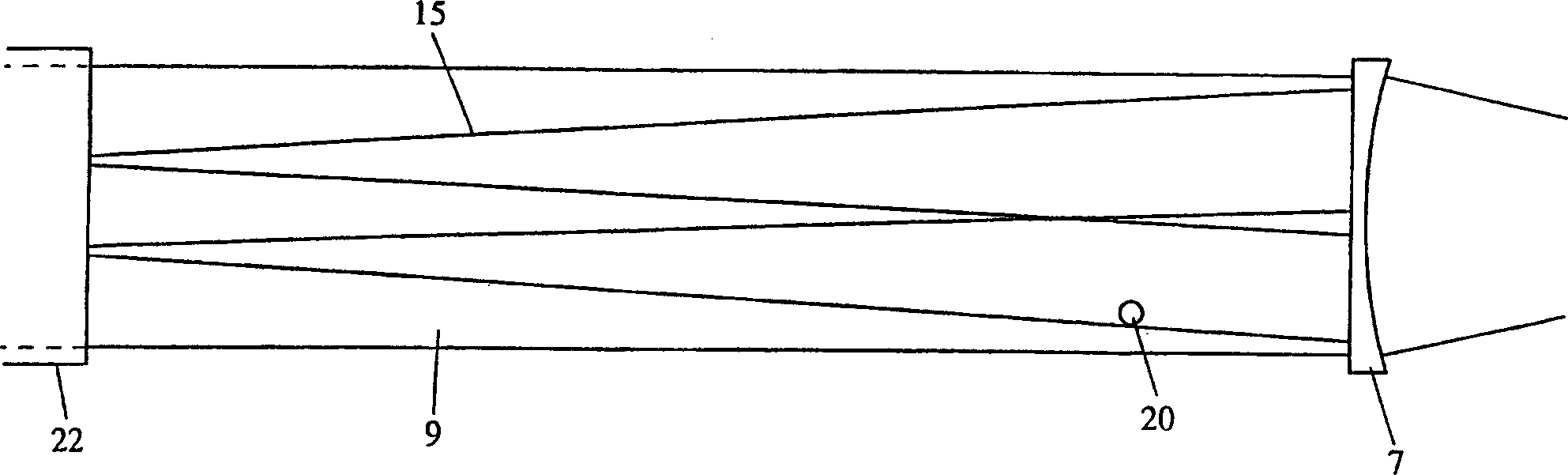

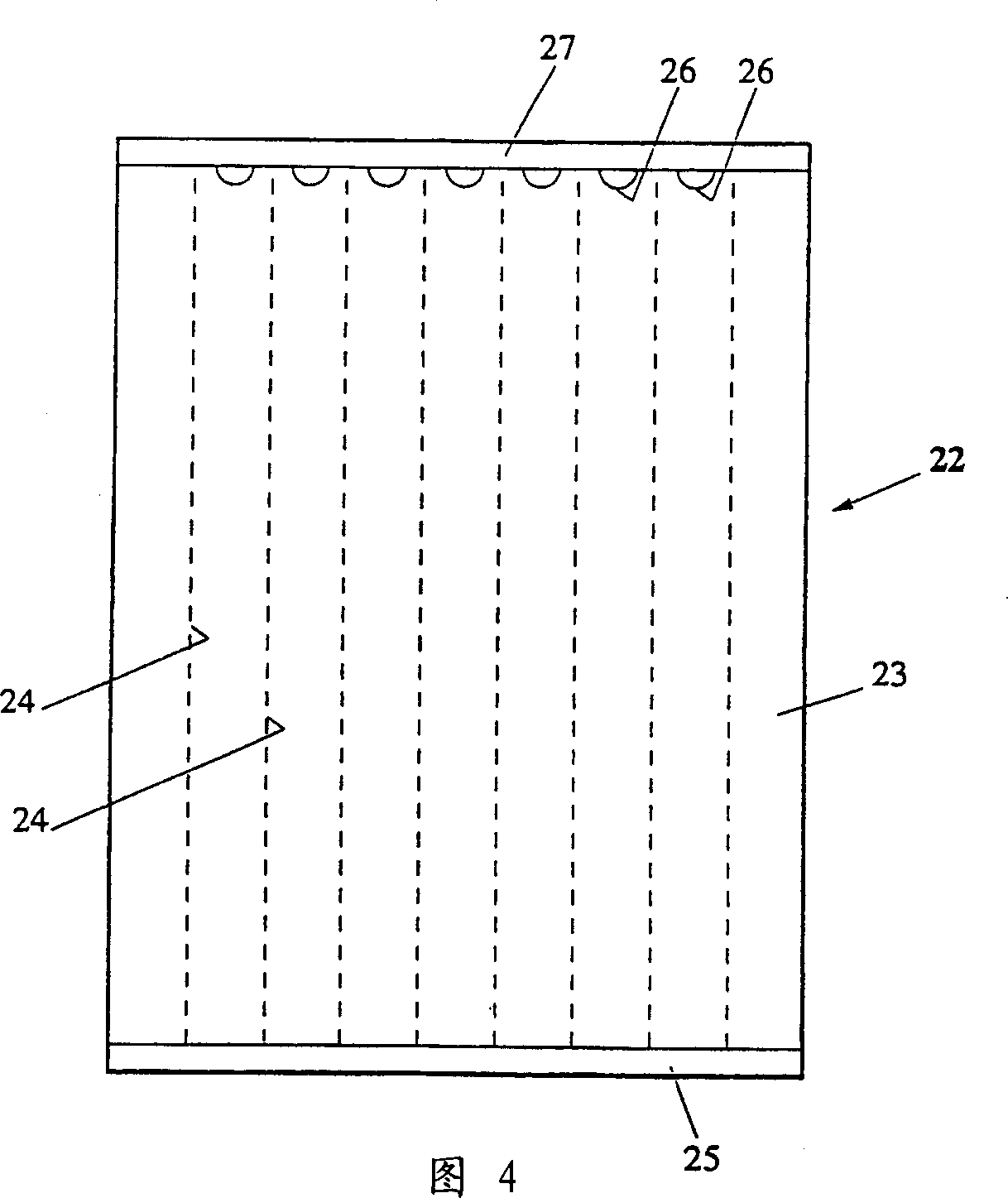

[0037] According to Fig. 1 at first, this industrial stamping machine safety system according to the present invention comprises: a laser emitting device 1, and this device has a laser emitter 2, such as a laser diode; The laser beam 3 emitted in 2 is transformed into a continuous planar laser beam 9 .

[0038] Figure 2 is a cross-sectional view of a continuous planar laser beam emitted by the security system according to the invention, before correction, along the line A-A in Figure 1 . This laser beam 9 has a substantially constant transverse width W along its length. Furthermore, the continuous planar laser beam 9 has a substantially constant thickness T. According to a possible configuration of the invention, the laser beam 9 has an average transverse width of about 50 mm and an average thickness of about 3 mm. The divergence angle of the laser beam 9 is preferably equal to or less than 0.1%. It will be appreciated that other configurations are possible, depending on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com