Conductor pattern formed by magnetic force

A conductor pattern, magnetization pattern technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, chemical/electrolytic methods to remove conductive materials, etc., can solve problems such as rising costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

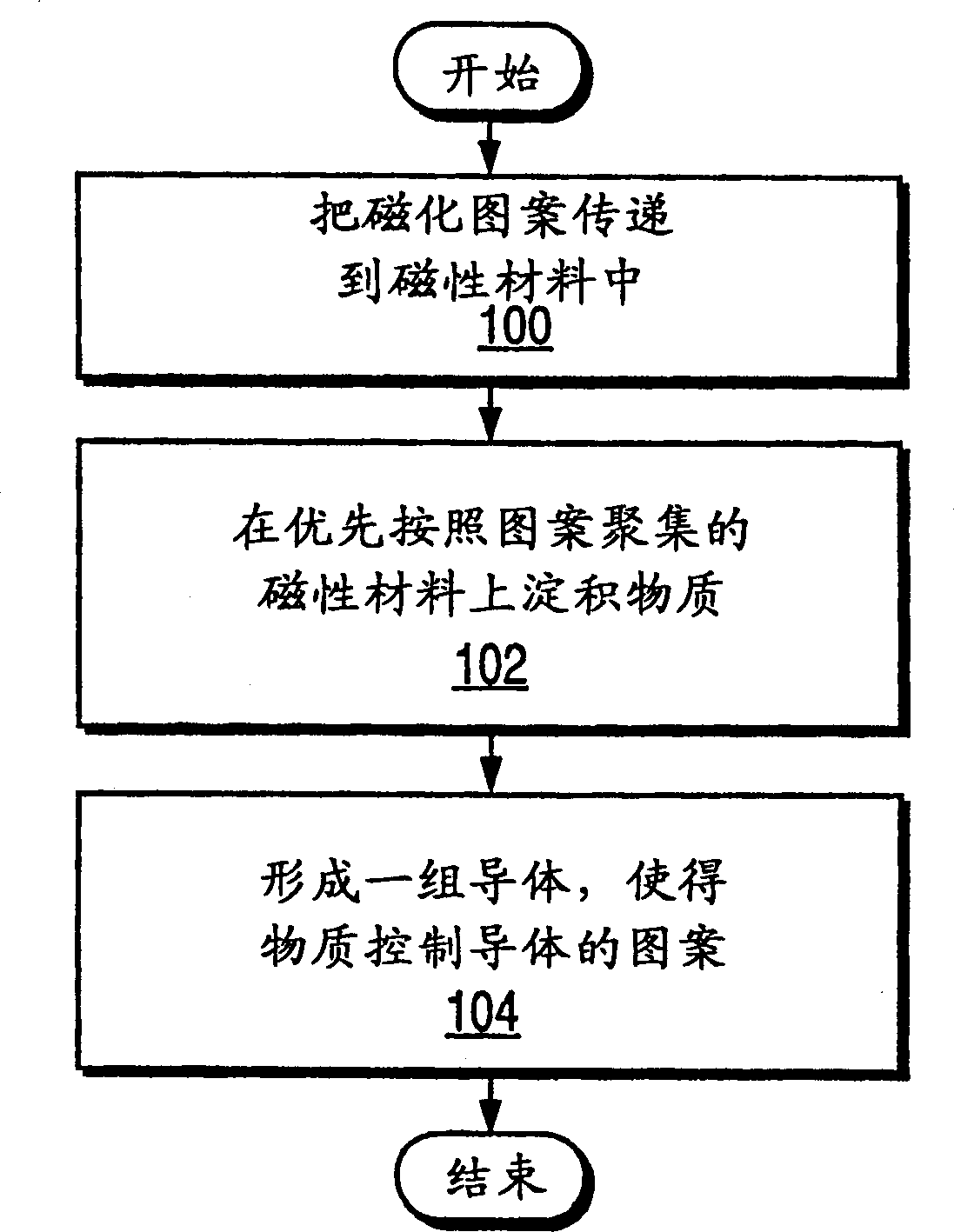

[0014] figure 1 A method of forming a conductor pattern using magnetic force according to the present technology will be described by way of example.

[0015] At step 100 a magnetization pattern is transferred into a magnetic material. In one embodiment, in step 100 said pattern is transferred into said magnetic material provided on a magnetic tape.

[0016] The pattern passed in step 100 can be any pattern. The pattern can be tailored to the specific use of the conductor. Various examples of uses include conductors associated with memory bit lines and / or word lines.

[0017] In step 102 , a substance preferentially assembled, ie aggregated, according to the pattern delivered in step 100 is deposited on the magnetic material. This substance protects the regions of magnetic material in a pattern corresponding to the desired pattern of the conductor to be formed.

[0018] At step 104, a set of conductors is formed such that the substance controls the pattern of the conducto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com