Reflecting composite prism and optical pick-up with the prism

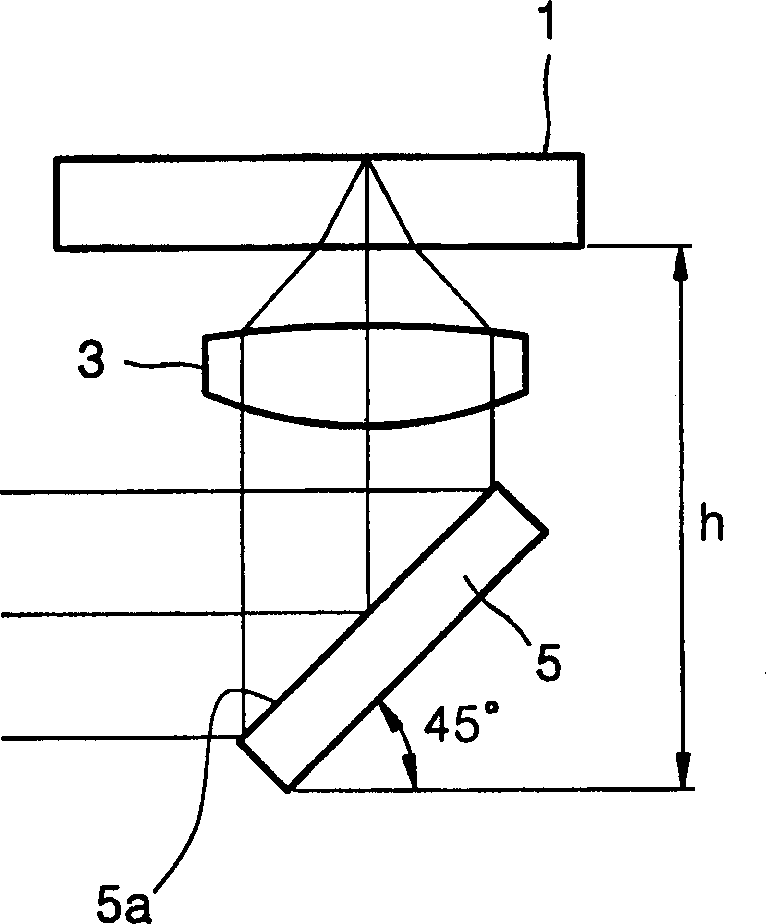

A compound prism and reflective technology, which is applied in the direction of integrated optical head device, beam guiding device, optical recording/reproduction, etc., can solve the problems of 5 large mirrors and difficulties in producing compact/thin optical pickup devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

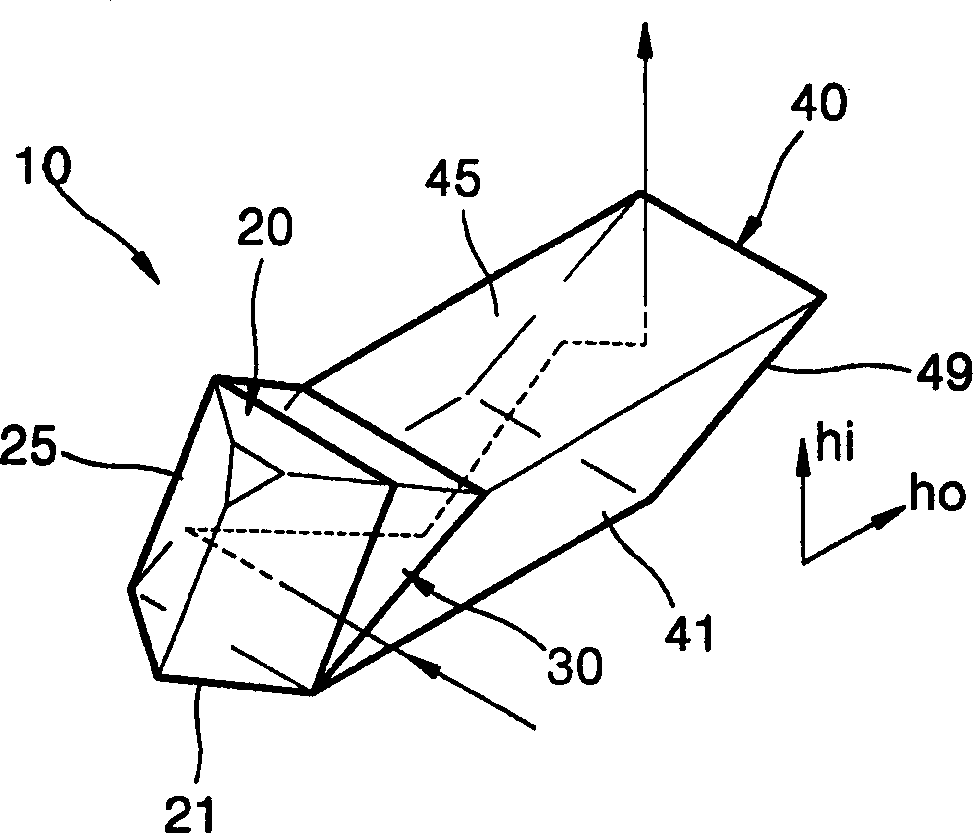

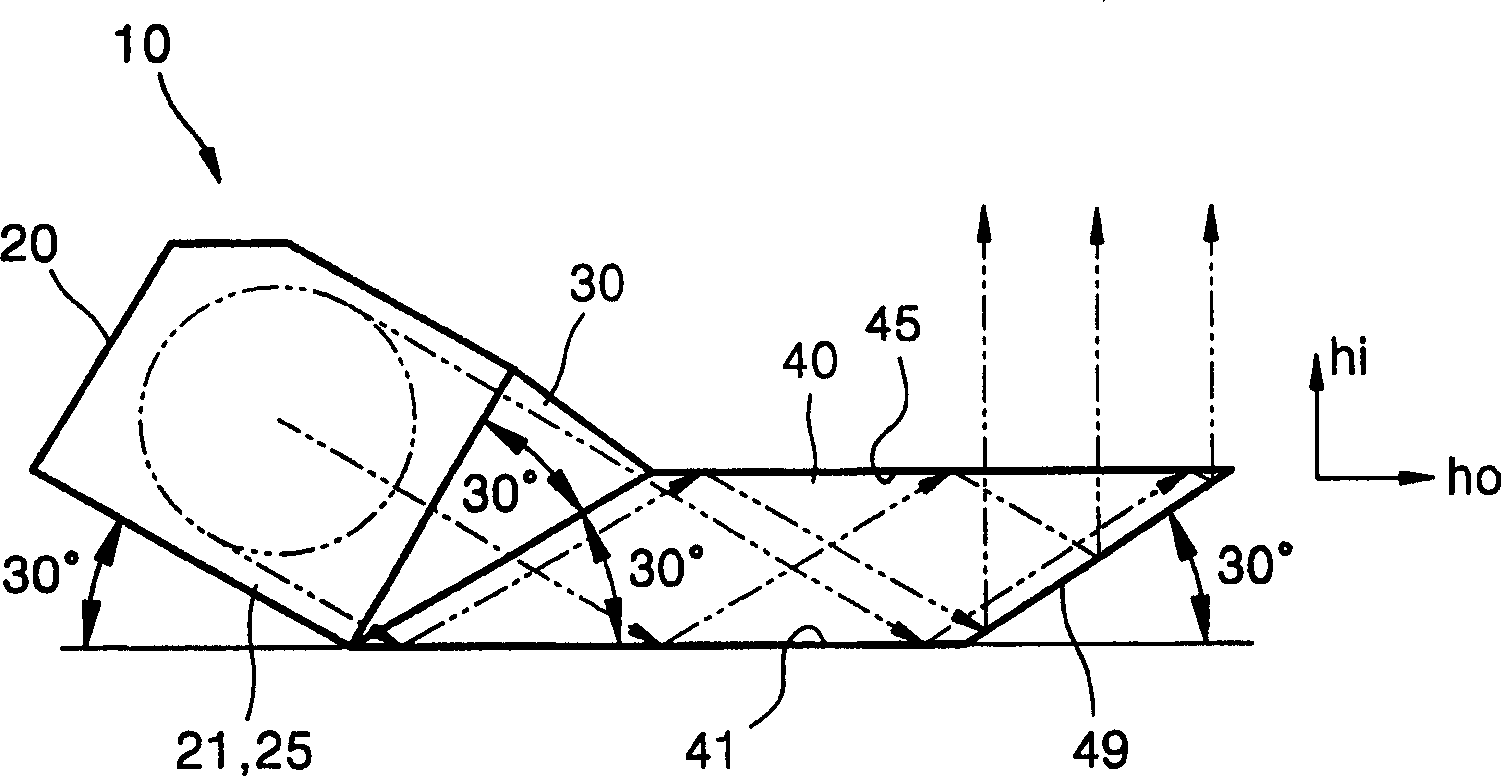

[0028] refer to figure 2 , the reflective composite prism 10 according to the present invention includes a first prism 20 and a second prism 40 . A light beam output from a light source (not shown) substantially parallel to the horizontal plane is input to the first prism 20, the light beam being perpendicular to the direction of the height hi of the optical system. The size of the light beam with respect to the height hi direction is reduced by utilizing the angle difference between the respective surfaces of the first prism 20 and the second prism 40 . Then, the light beam is reflected by the surface of the second prism 40 which forms an angle of less than 45° with respect to the horizontal plane, and is output in the height hi direction.

[0029] Here, considering an example in which the reflective compound prism 10 according to the present invention is used in an optical pickup device, the height hi direction of the optical system is assumed to indicate a direction along...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com