Method for preparing non-water electrolyte battery

A non-aqueous electrolyte and electrolyte technology, applied in non-aqueous electrolyte batteries, non-aqueous electrolyte batteries, secondary batteries, etc., can solve the problems of internal short circuit, strength reduction, difficulty in preparing batteries, etc., and achieve the effect of improving battery output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

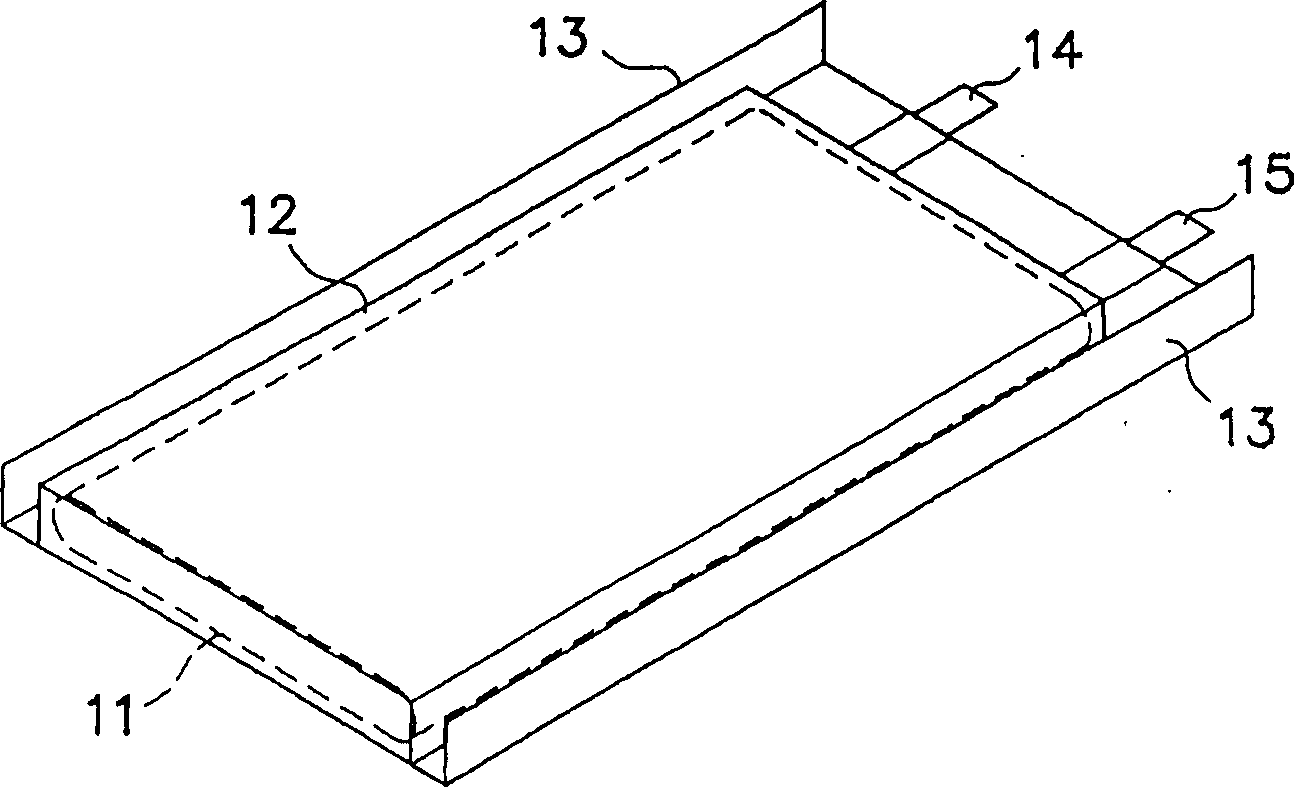

[0038] The prepared nonaqueous electrolyte battery, which includes an elliptical wound power generating element composed of a positive electrode, a separator, and a negative electrode, was housed in a metal-laminated resin film case with a nonaqueous electrolyte (not shown). The metal laminated resin film case can be produced by thermally welding the metal laminated resin films.

[0039] The appearance of the non-aqueous electrolyte battery of embodiment 1-10 is shown in figure 2 middle. exist figure 2 Among them, reference numeral 11 denotes a power generating element, reference numeral 12 denotes a battery case, reference numeral 13 denotes a thermally welded part of the battery case, reference numeral 14 denotes a positive terminal, and reference numeral 15 denotes a negative terminal.

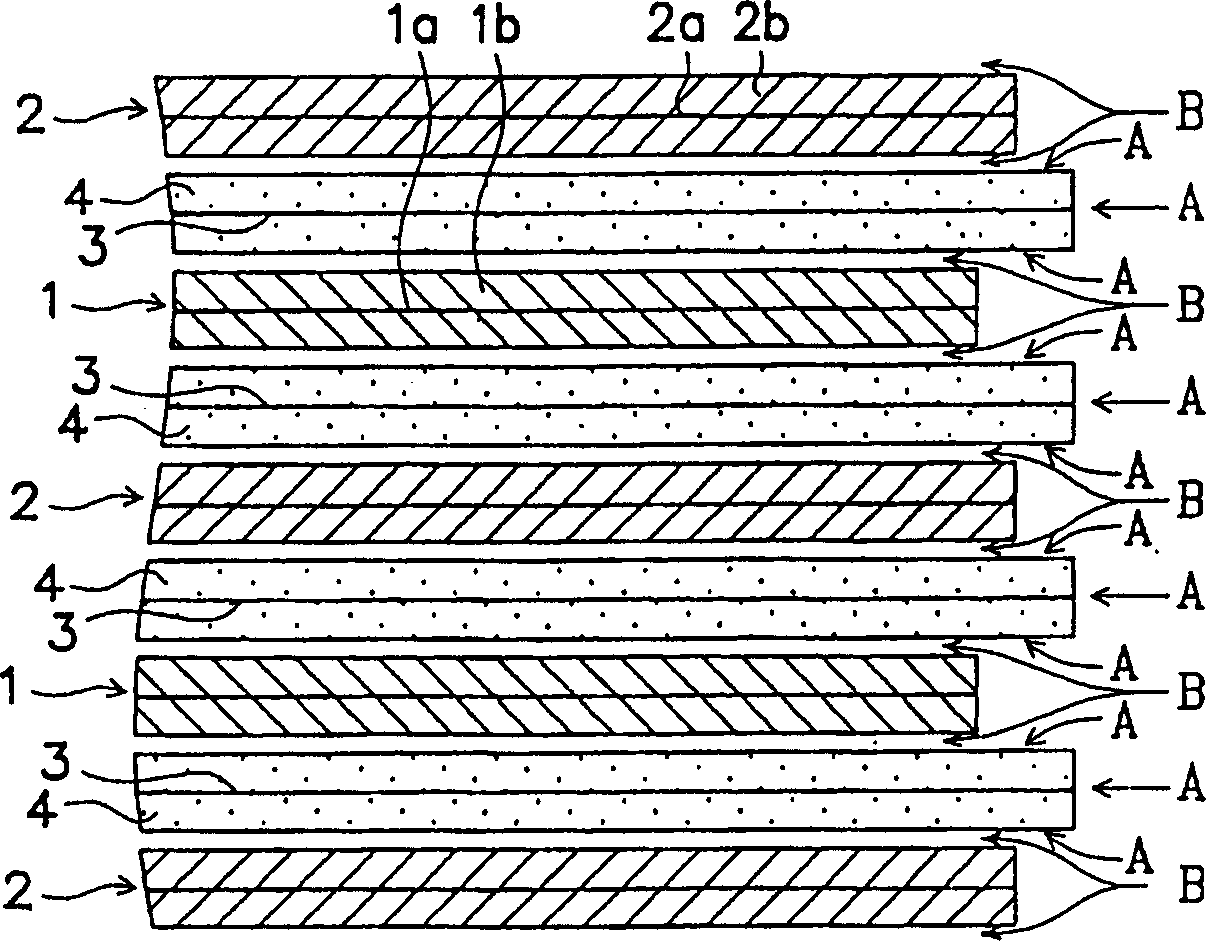

[0040] The positive electrode can be prepared as follows: mix 90% by weight of lithium-cobalt composite oxide as the positive electrode active material, 6% by weight of PVDF as the bind...

Embodiment 11

[0050] In Example 11, except that the pressing process is not implemented during the heating of the heating and cooling steps but only during the cooling of the heating and cooling steps and the pressure is 0.1 MPa / cm 2 A non-aqueous electrolyte battery having the same composition as in Example 1-10 was prepared in the same manner as in Example 1-10 except that it was carried out under the same conditions. The battery is referred to as "A11".

Embodiment 12

[0052] In Example 12, except that the pressing process is not carried out during the cooling process of the heating and cooling step but only during the heating process of the heating and cooling step and the pressure is 0.1 MPa / cm 2 A non-aqueous electrolyte battery having the same composition as in Example 1-10 was prepared in the same manner as in Example 1-10 except that it was carried out under the same conditions. The battery is referred to as "A12". Comparative Example 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com