Vehicle and ship lubricating oil real time detection method and its device

A real-time detection, lubricating oil technology, applied in the direction of vehicle components, transportation and packaging, electrical circuits or fluid pipelines, etc., can solve the problems of time consumption, loss of lubrication effect, loss of lubrication, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

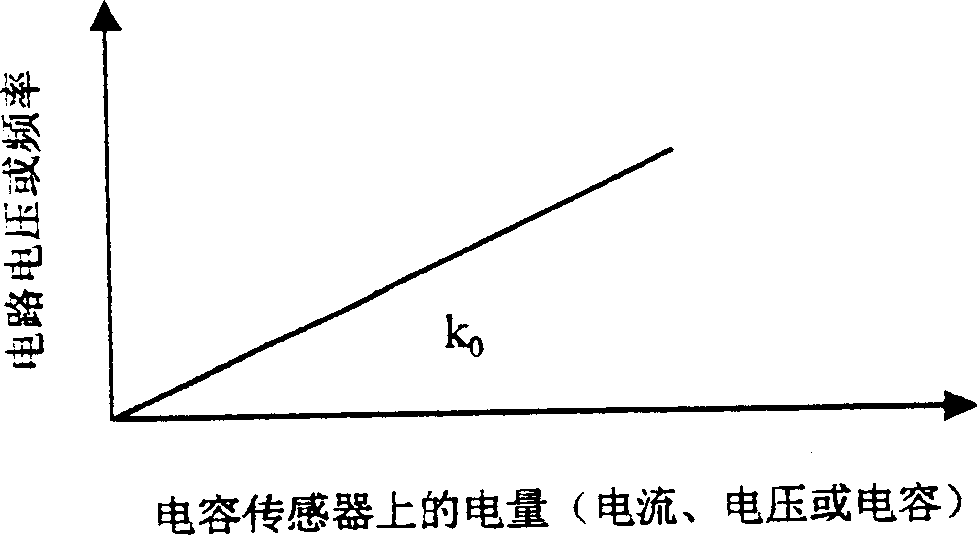

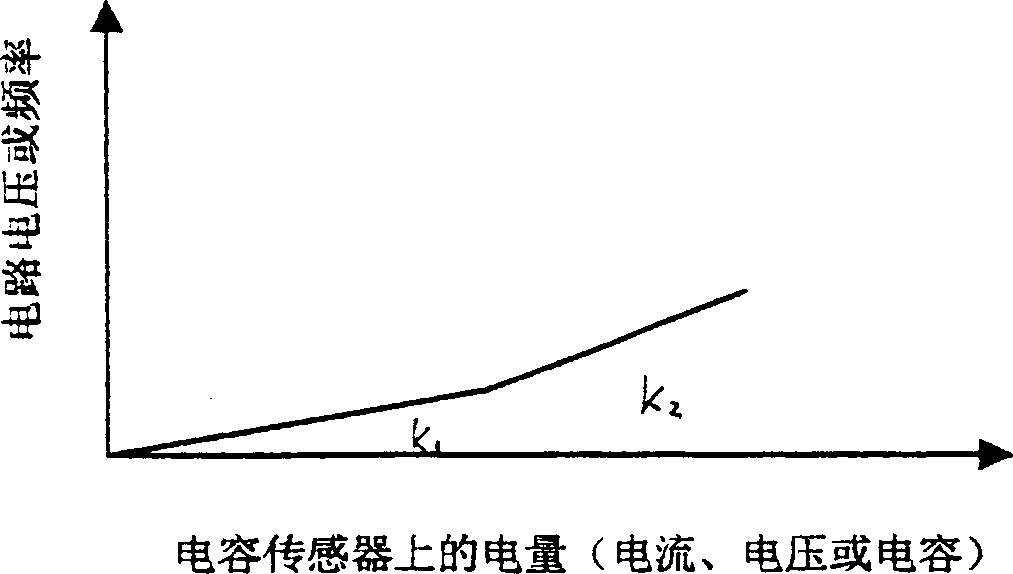

[0009] Because the additives contained in the lubricating oil often have a polar bond, and it is usually negative polarity; the lubricating oil will be ionized after oxidation, and after complex chemical reactions, there will be various ions in the lubricating oil. These ions are all charged and can be Detected by various electrical measuring devices, the present invention uses the capacitance method to measure these ions, and can detect the reduction of additives in lubricating oil and the severity of lubricating oil oxidation after simple data processing;

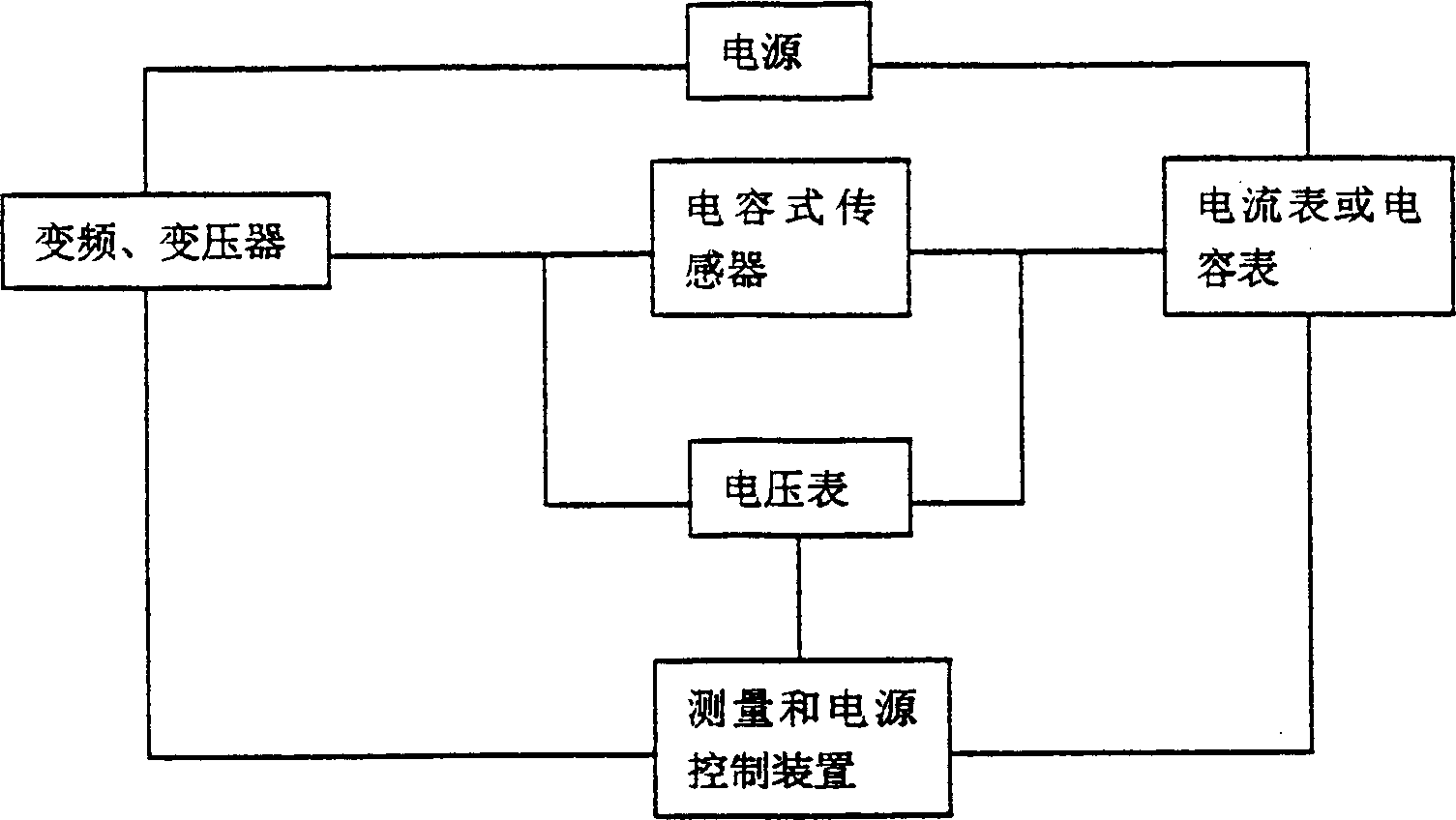

[0010] Please refer to the attached figure 1 In the circuit block diagram of the present invention, a capacitive sensor is placed in the lubricating oil for vehicles and ships, and the two electrodes of the capacitive sensor are respectively connected with an ammeter or a capacitive meter and a variable frequency transformer, and a voltmeter and a variable voltage frequency converter are connected in parallel at the two po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com