Compound switch set for vehicle

A composite switch and switch group technology, applied in the direction of electric switches, vehicle components, electrical components, etc., can solve the problems of time-consuming assembly and lack of reliability of electrical connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

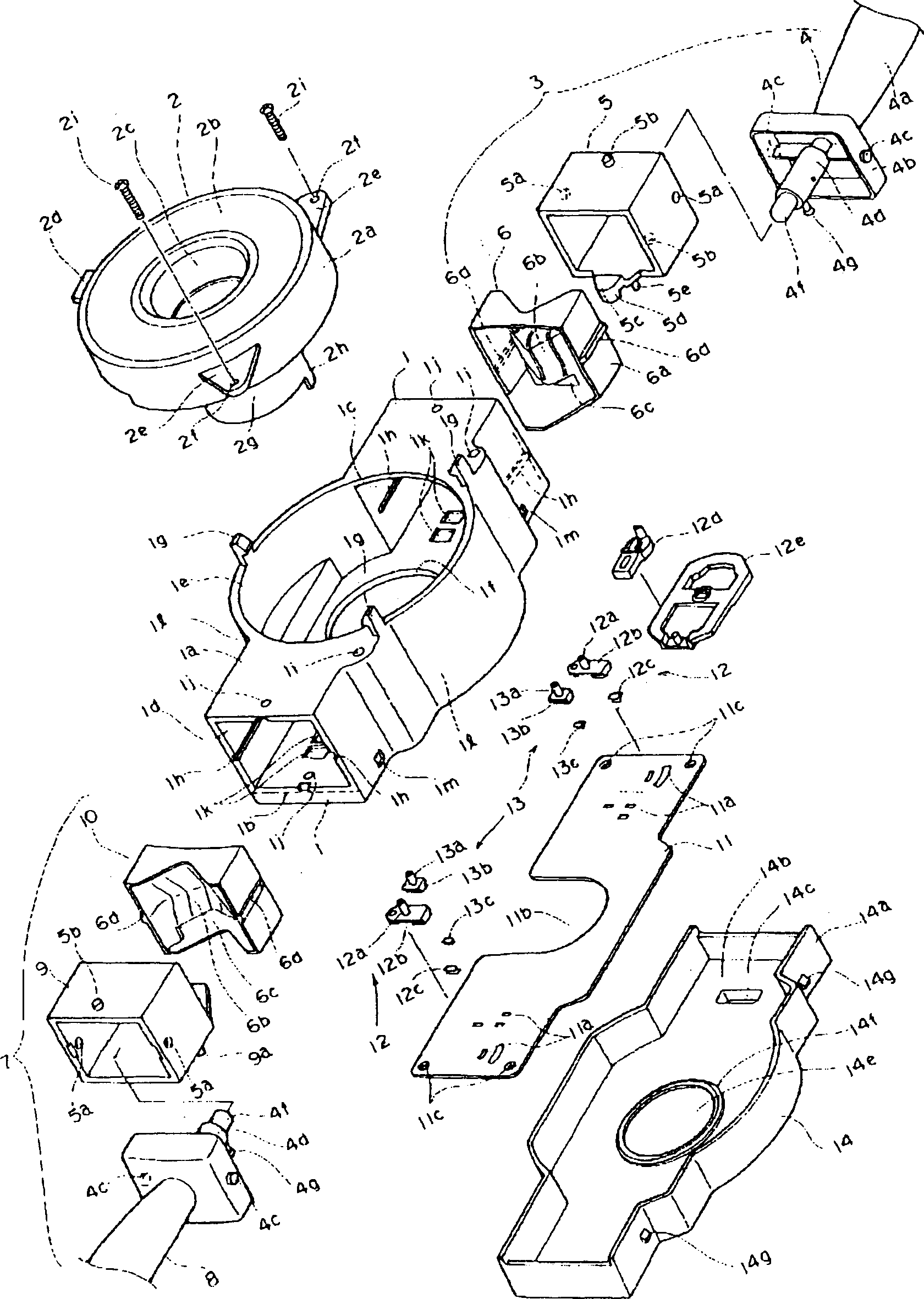

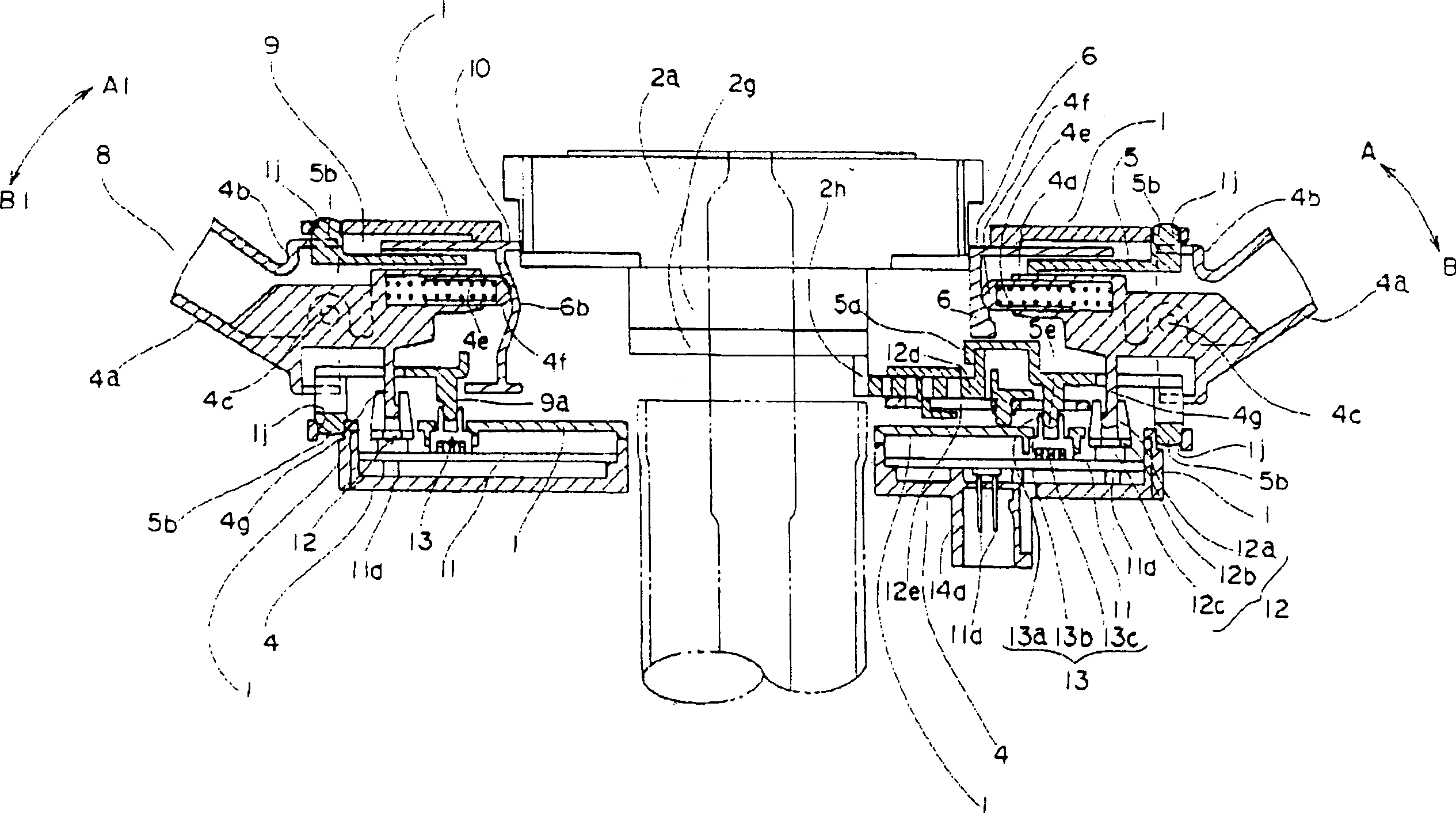

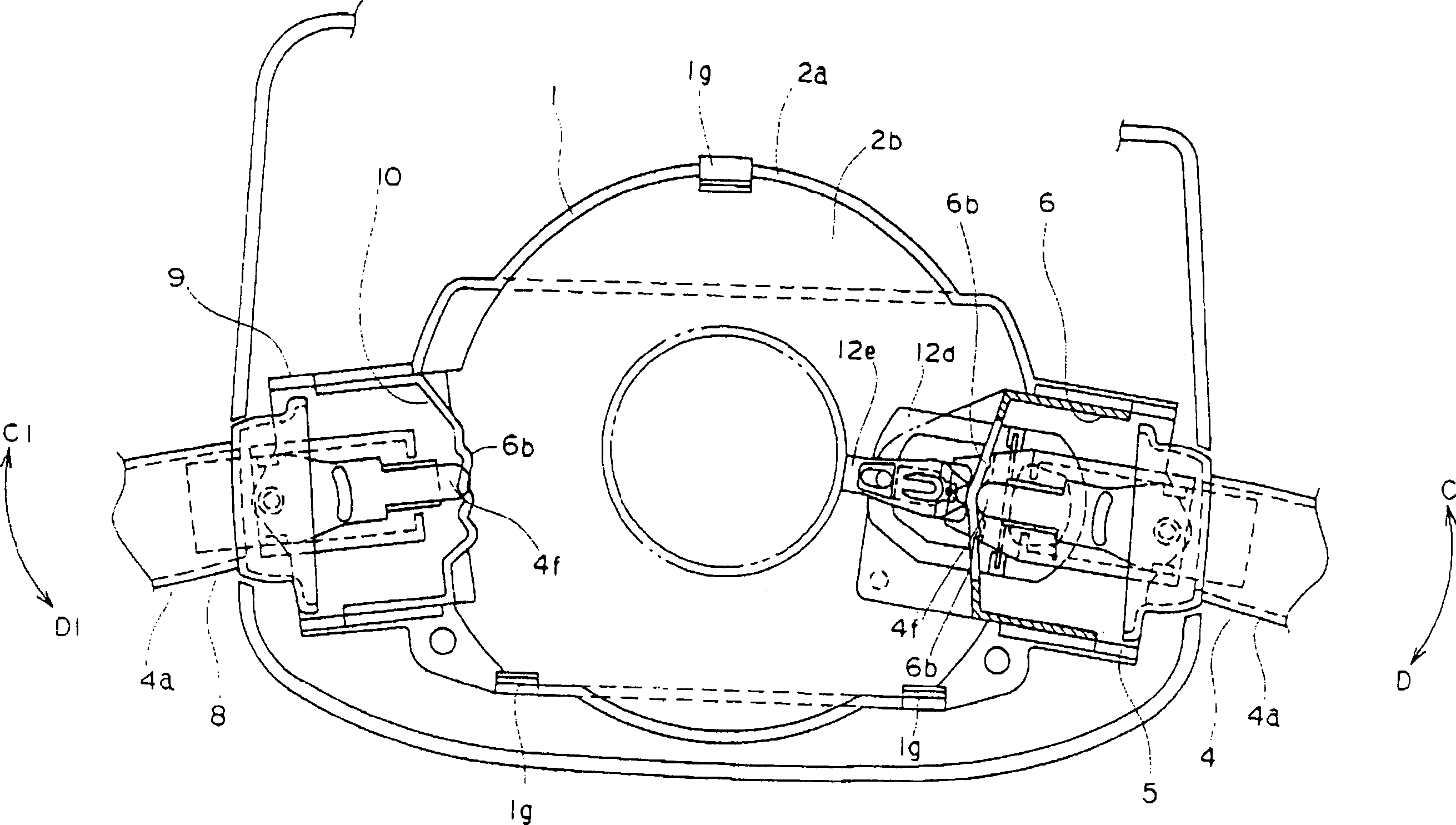

[0044] Utilize figure to illustrate the embodiment of composite switch group for vehicle of the present invention, figure represents respectively: figure 1 It is an exploded perspective view of an embodiment of the composite switch group for vehicles of the present invention, figure 2 It is a cross-sectional view of the main part of the vehicle composite switch group embodiment of the present invention, image 3 It is a longitudinal sectional view of the main part of the embodiment of the compound switch group for vehicles of the present invention.

[0045] Next, combine Figure 1 ~ Figure 3 The structure of the composite switch group for vehicles of the present invention will be described.

[0046] hood 1, such as figure 1 As shown, it is in the shape of a long box made of insulating resin. There is a rectangular opening 1c at one end in the longitudinal direction, and a rectangular opening 1d at the other end in the longitudinal direction. The left and right walls of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com