Method for dyeing cloth and collar sleeve and its device

A leader, dyeing technology, applied in the field of bleaching and dyeing, can solve the problems of large equipment area, difficult to dye through defects, low production efficiency, etc., to achieve the effect of small equipment area, stable dyeing cloth size, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

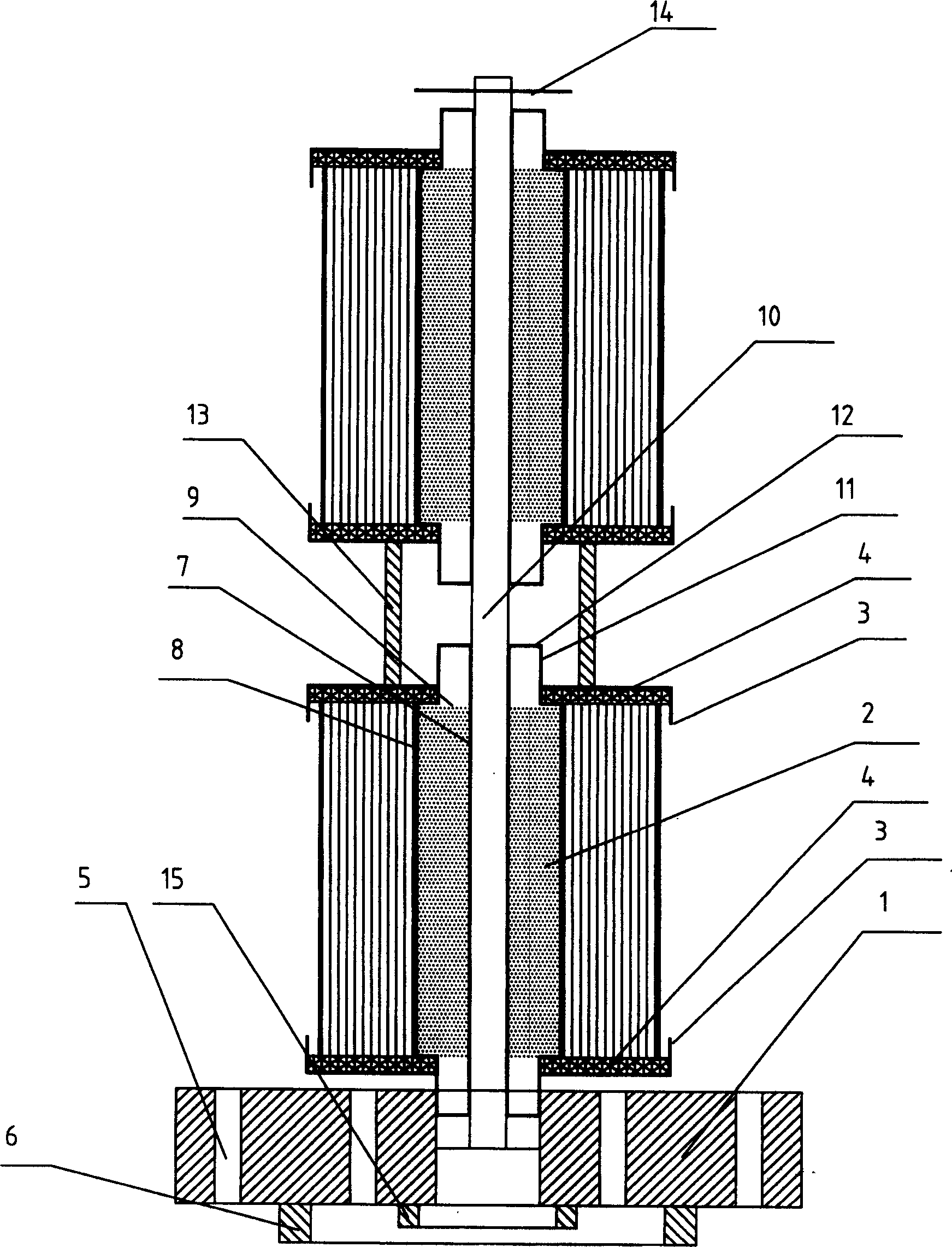

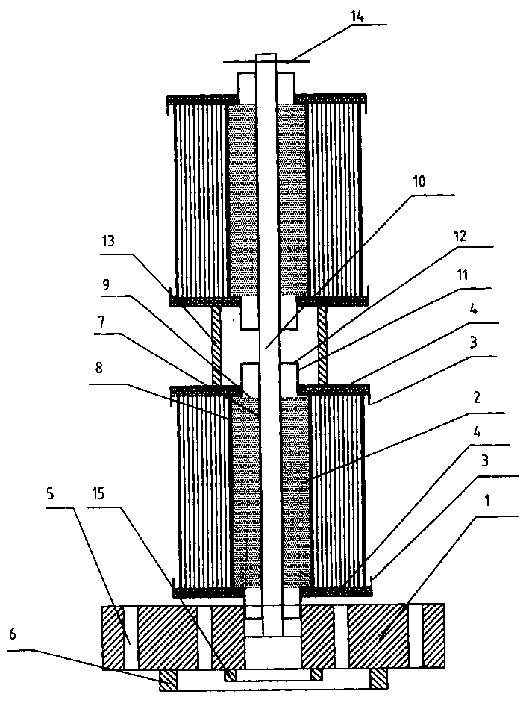

[0013] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0014] The method for dyeing cloth and leader of the present invention is achieved in that cloth or leader is wound on the cloth roll shaft, and the cloth roll shaft is a hollow shaft, and its outer wall is uniformly and densely arranged with small holes, and then wraps the cloth with sealing material The two sides of the roll cloth wound on the cloth roll shaft are sealed, one end of the shaft hole is closed, the dye solution is pumped into the other end of the shaft hole, and the dye solution on the dye vat enters the roll through the densely distributed small holes on the outer wall of the shaft. Each layer of cloth that permeates through the rolled cloth flows back into the dye vat.

[0015] The cloth dyeing and leader device of the present invention is realized in this way, mainly consisting of a base 1, a cloth roll shaft 2 arranged on the base 1, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com