System for connecting filament to current input header

A technology for connecting to and filaments, applied in the field of incandescent lamps, which can solve the problems of long assembly time, difficult filament assembly, and damage to the filament.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

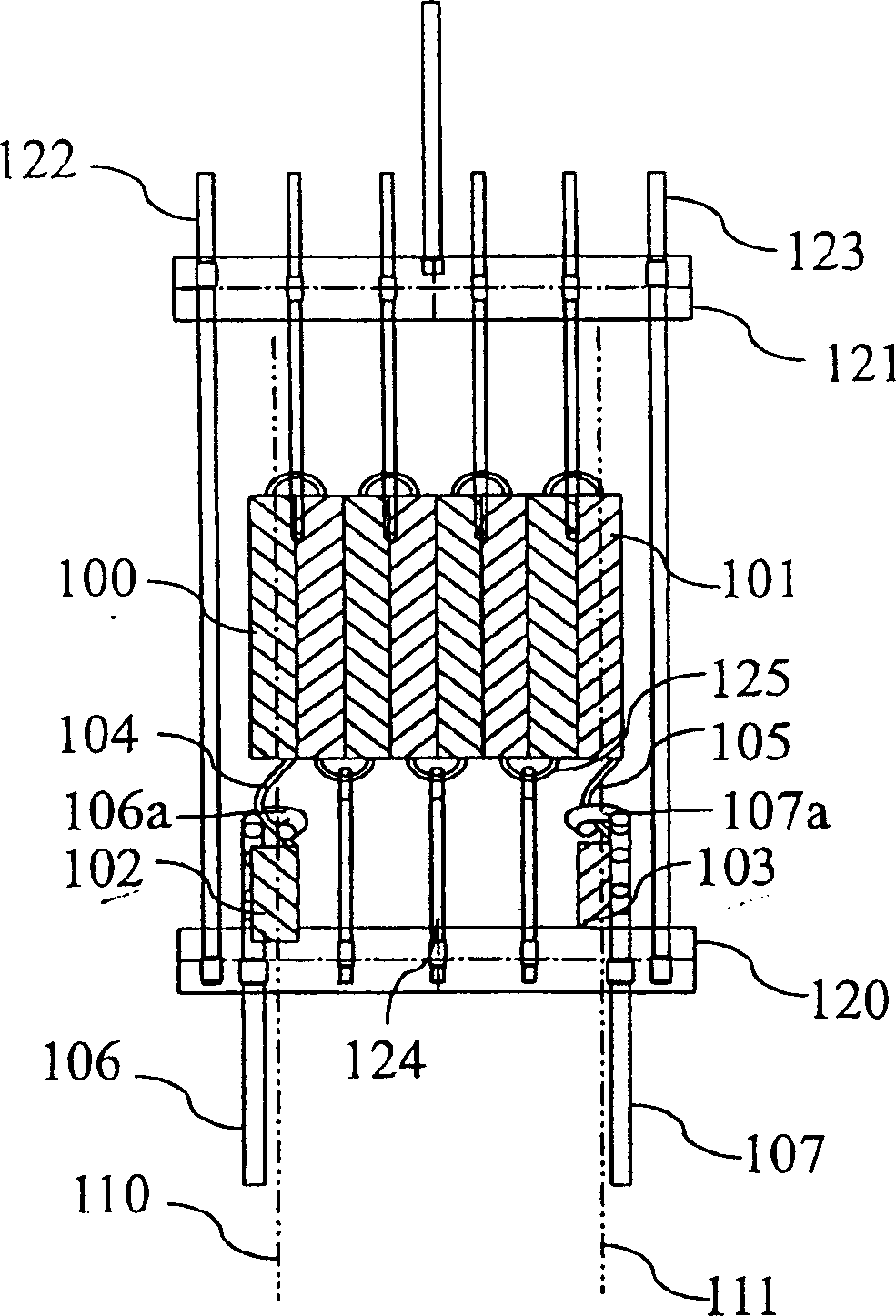

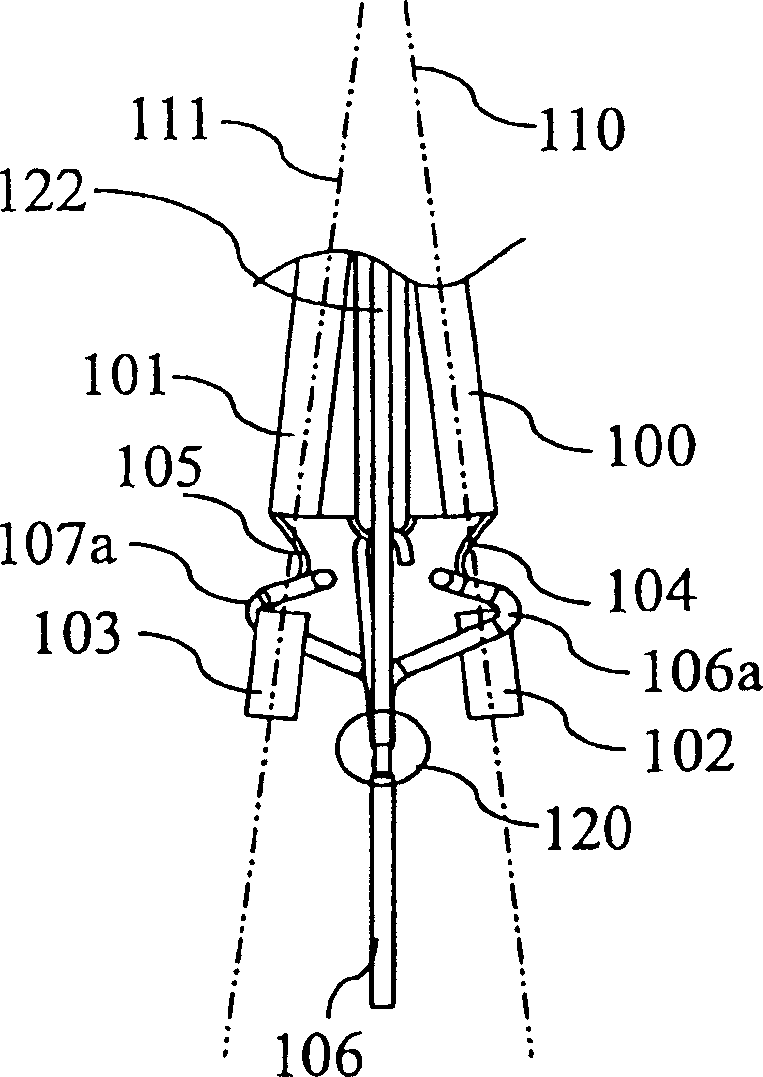

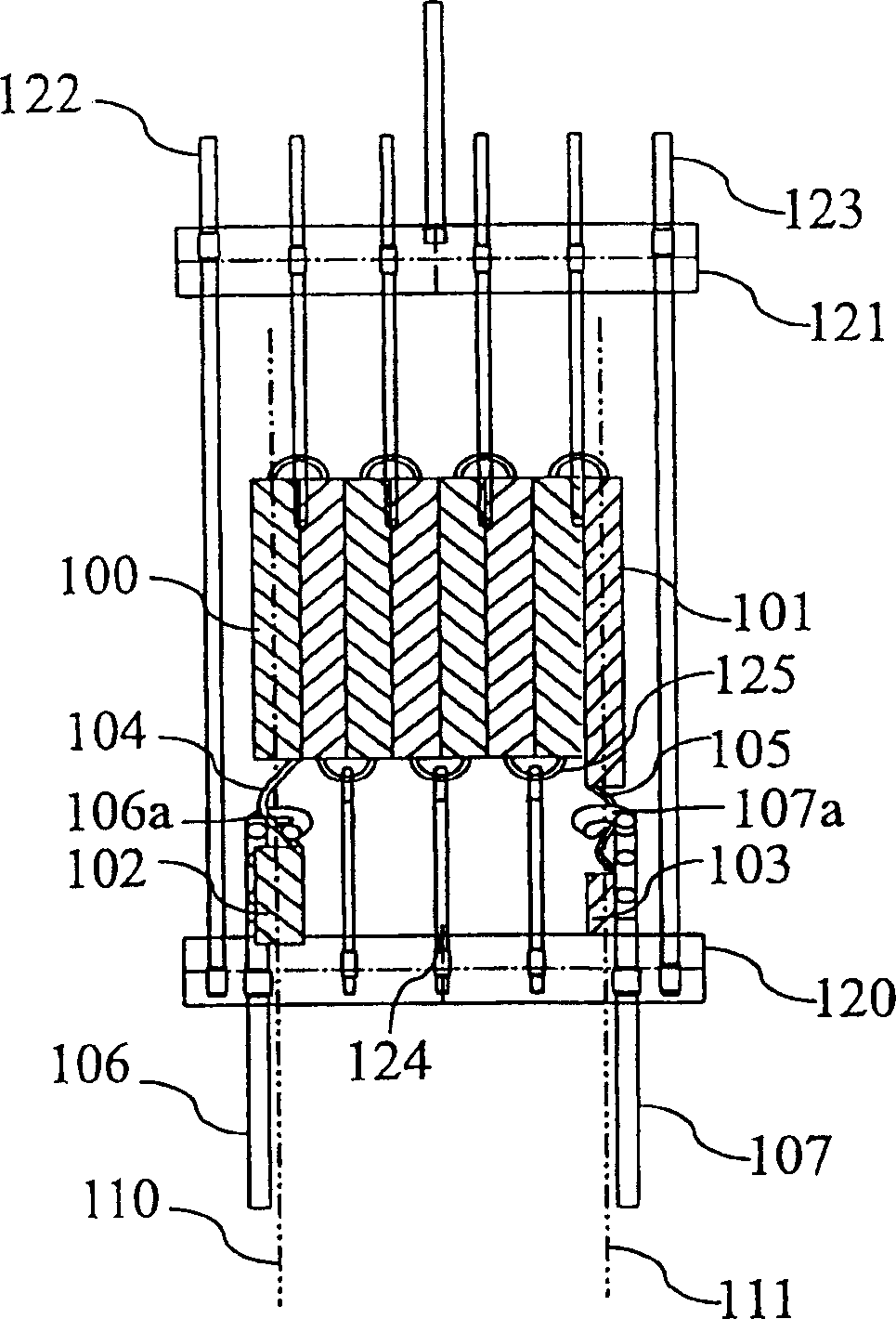

[0019] attached Figure 1a and 1b A prior art lamp is shown. The problem solved by the invention can be seen from the description of such a lamp.

[0020] This lamp comprises a first filament part 100, a second filament part 101, a first auxiliary part 102, a second auxiliary part 103, a first spacer 104, a second spacer 105, a first Metal support bar 106 , second metal support bar 107 including second hook 107 a , bridges 120 and 121 connected by metal bars 122 and 123 , spacer 124 , and filament ring 125 . The first filament part 100 has a first rotation axis 110 , and the second filament part 101 has a second rotation axis 111 . The axes of rotation of the hooks 106 a and 107 a substantially coincide with the first axis of rotation 110 and the second axis of rotation 111 . It will be considered below that the axis of rotation of the first hook 106 a is the first axis of rotation 110 and the axis of rotation of the second hook 107 a is the second axis of rotation 111 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com