Pick-up feeder, information regenerator and information recorder

A feeding device and information recording technology, which is applied in data recording, information storage, recording information storage, etc., can solve the problems of difficulty in miniaturization of the device, large size of resin spring, and large friction load, etc., to prevent recording/reproduction quality The effect of lowering, reducing the load, and reducing the imparting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

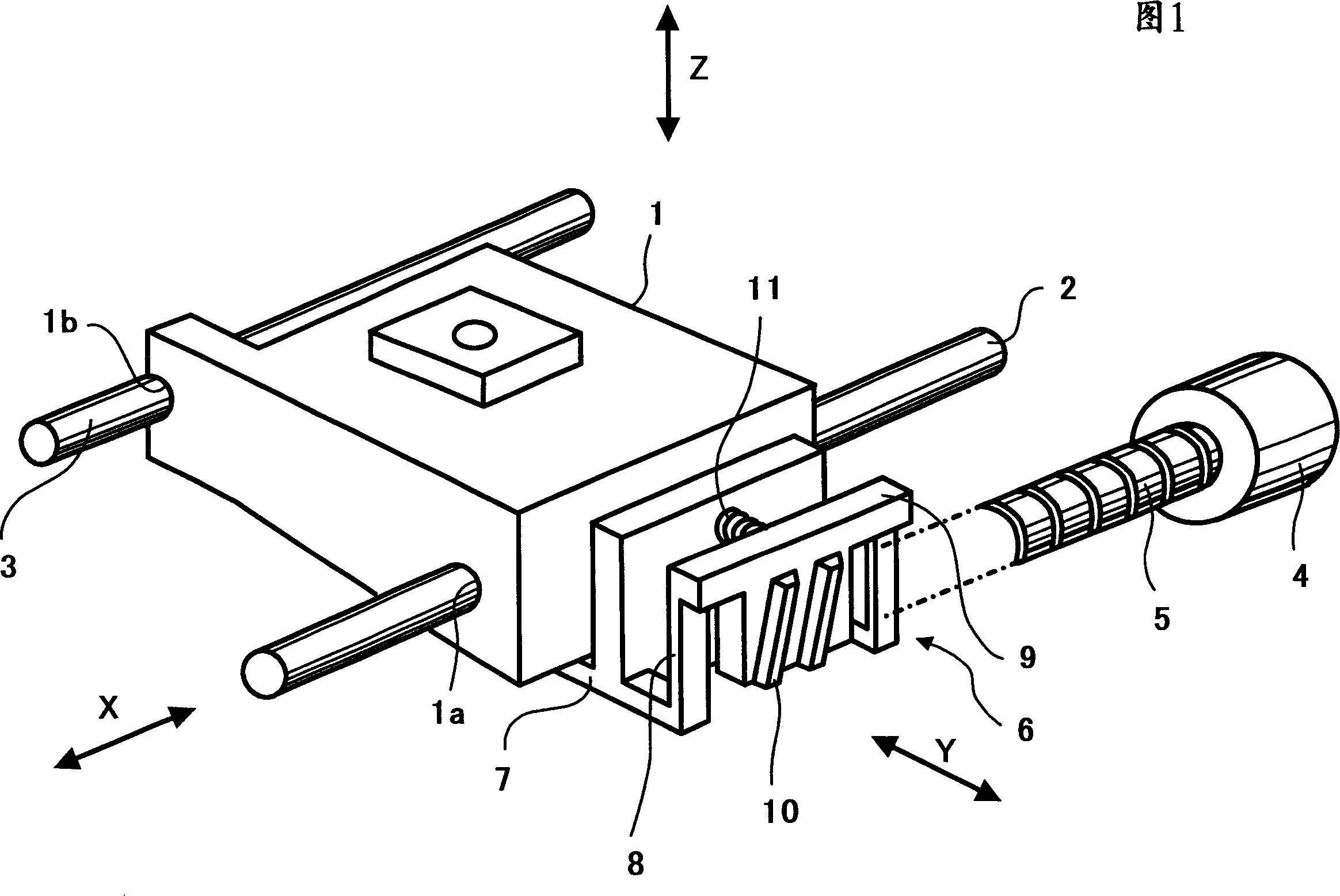

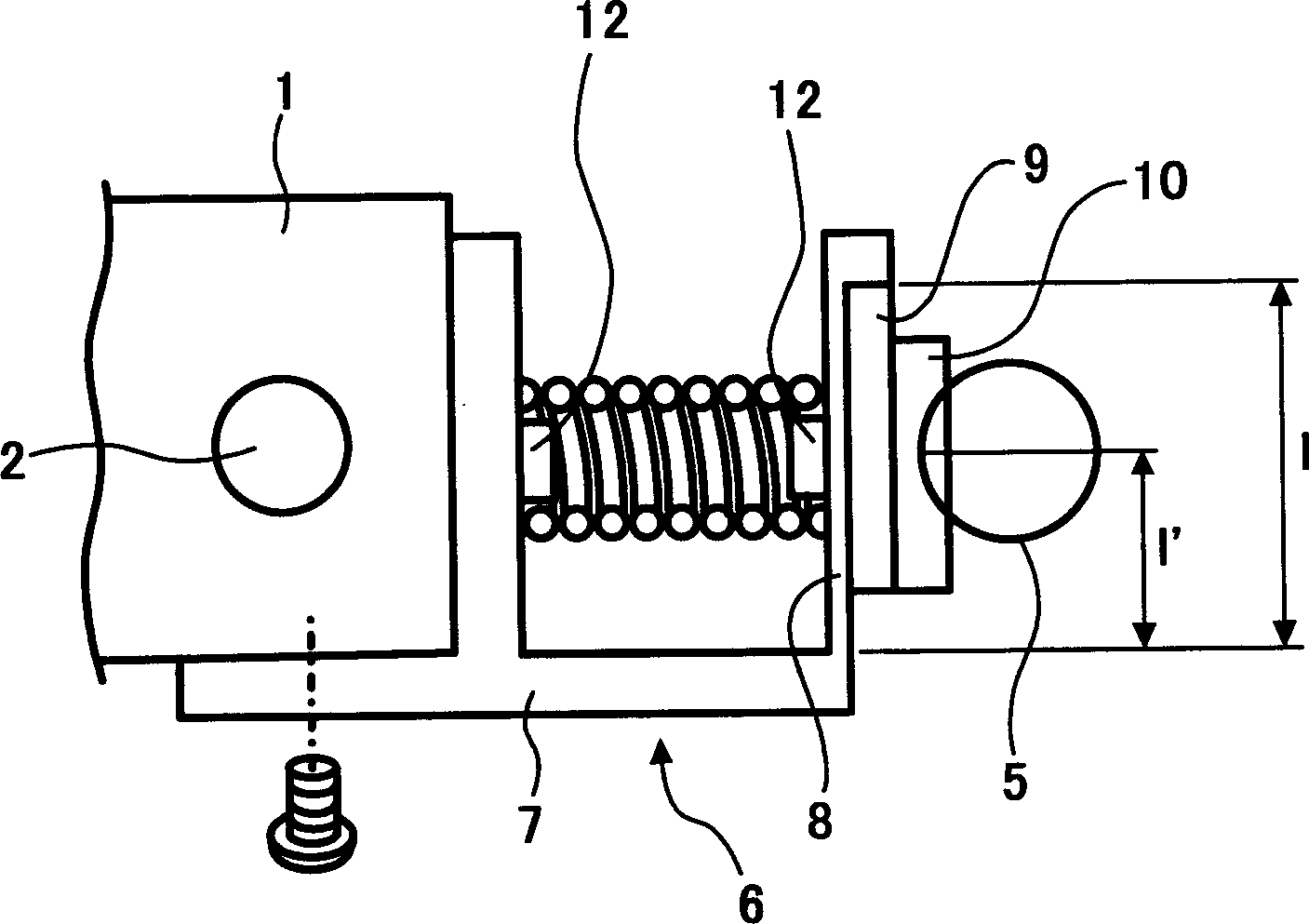

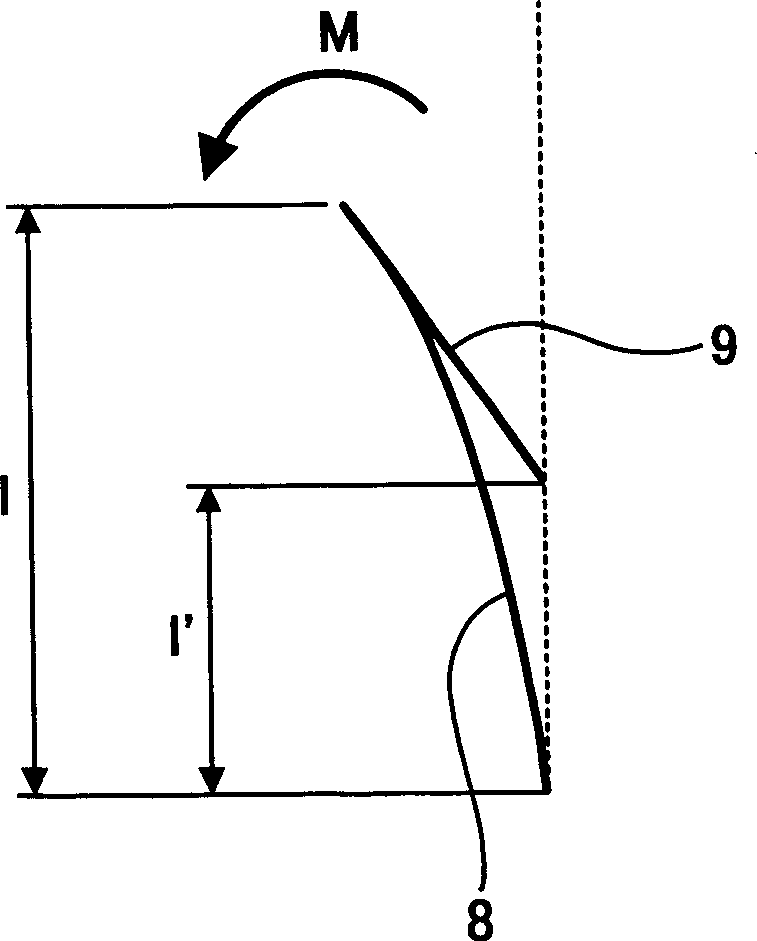

[0068] Fig. 1 is the perspective view of the device structure of the first embodiment of the present invention, among the figure, symbol 1 represents the pick-up that carries various optical parts for making the light irradiate the optical disc, and 2 represents that pick-up 1 is carried out along the radial direction of the optical disc. The first guide shaft for guidance, 3 represents the second guide shaft arranged in parallel with the above-mentioned first guide shaft 2, and guides the pickup 1 along the radial direction of the disc, 4 represents the motor, and 5 represents the lead screw composed of a cylindrical shaft , A helical groove is provided on the cylindrical shaft. The above-mentioned lead screw 5 is connected with the motor 4 and is driven to rotate. At this time, the central axis of the above-mentioned lead screw 5 coincides with the rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com