Three-phase integrated gas isolated bus

A technology of gas insulation and busbar, which is applied in the direction of fully enclosed busbar devices, electrical components, high-voltage air circuit breakers, etc., can solve the problems of the size limitation of the cross-section of the busbar shell, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] An embodiment of the invention is described below with reference to the following drawings, in which:

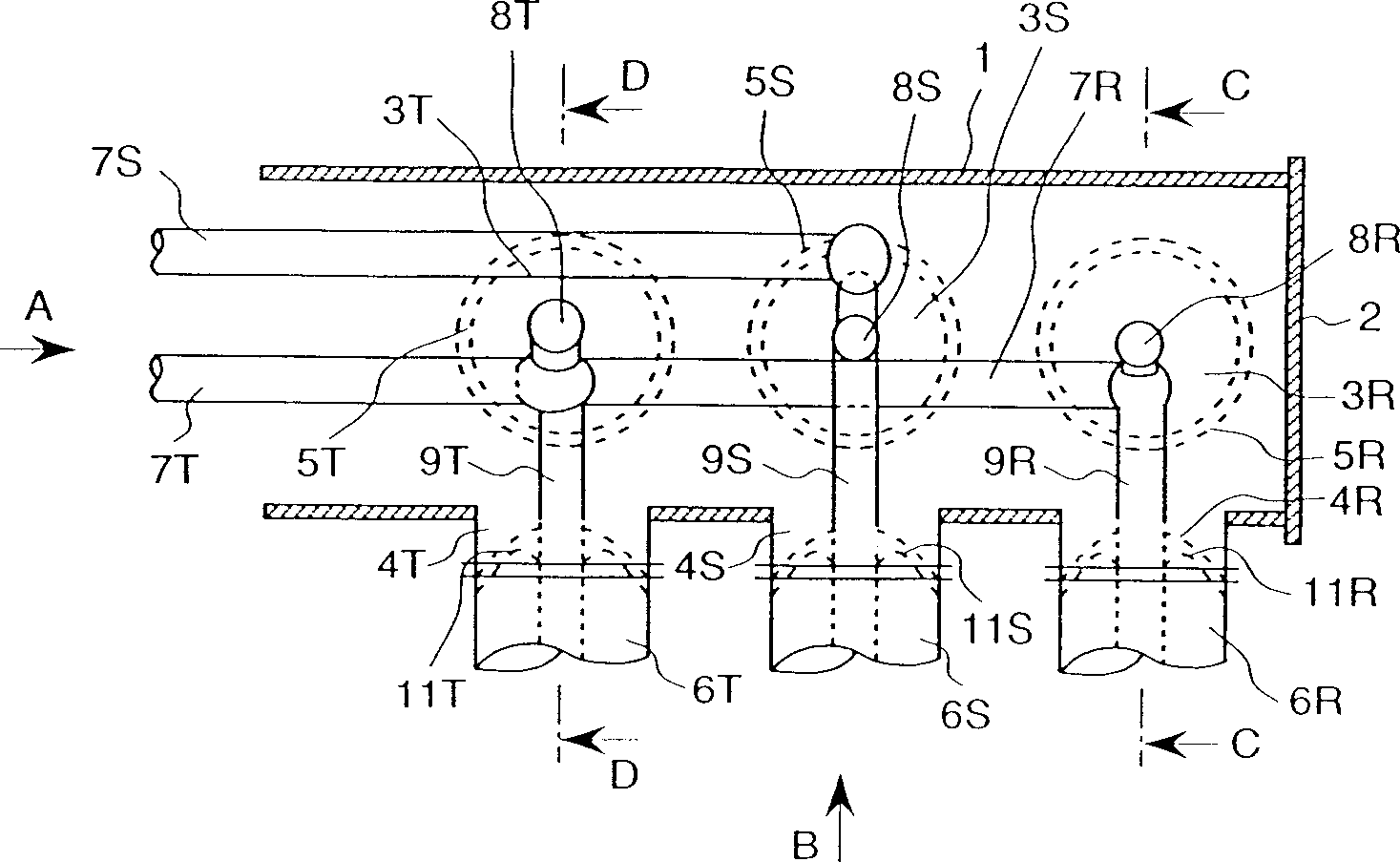

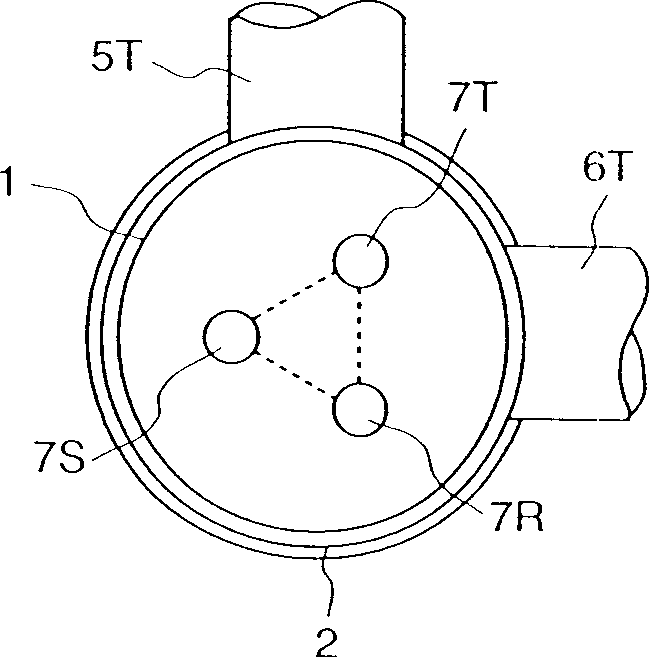

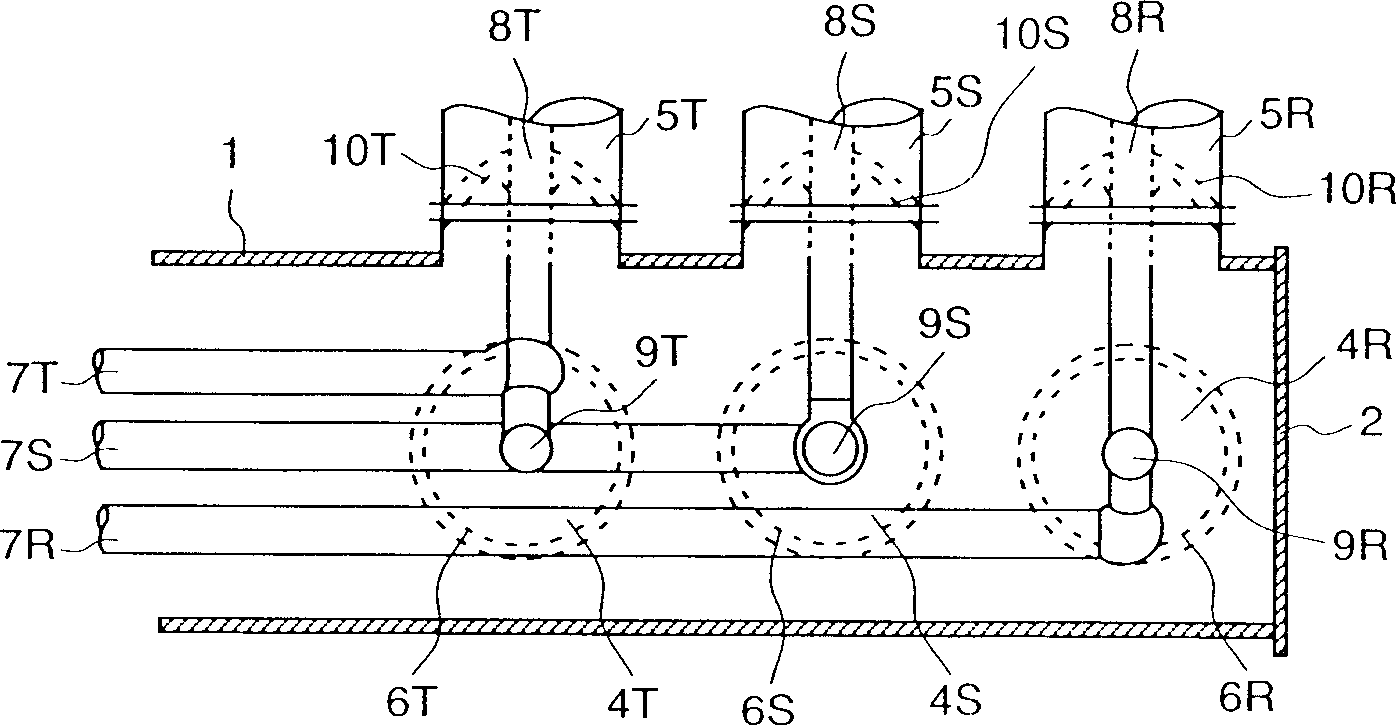

[0020] figure 1 It is a top view with a partial cross-sectional view of the three-phase integrated gas-insulated busbar of the present invention. figure 2 is along figure 1 The view from the direction of arrow A in the middle. image 3 is along figure 1 The view from the direction of the arrow B in the middle. Figure 4 is a perspective view of the connection between the main and branch buses.

[0021] exist Figures 1 to 4 Among them, the cylindrical busbar casing 1 is made of metal such as stainless steel, and a bolt mounting flange 2 is used on one side of the busbar casing to make it closed. The bus bar housing 1 is filled with insulating gas. Three vertical outlets 3R, 3S and 3T are formed on the top surface of the busbar housing 1 in the longitudinal direction (axial direction). The three vertical outlets 3R, 3S and 3T are formed on a straight line coax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com