Miniature creeping vehicle based on shape memory alloy driving

A technology of memory alloy and memory alloy spring, which is applied in the field of robots and can solve the problems of complex control sequence and large power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

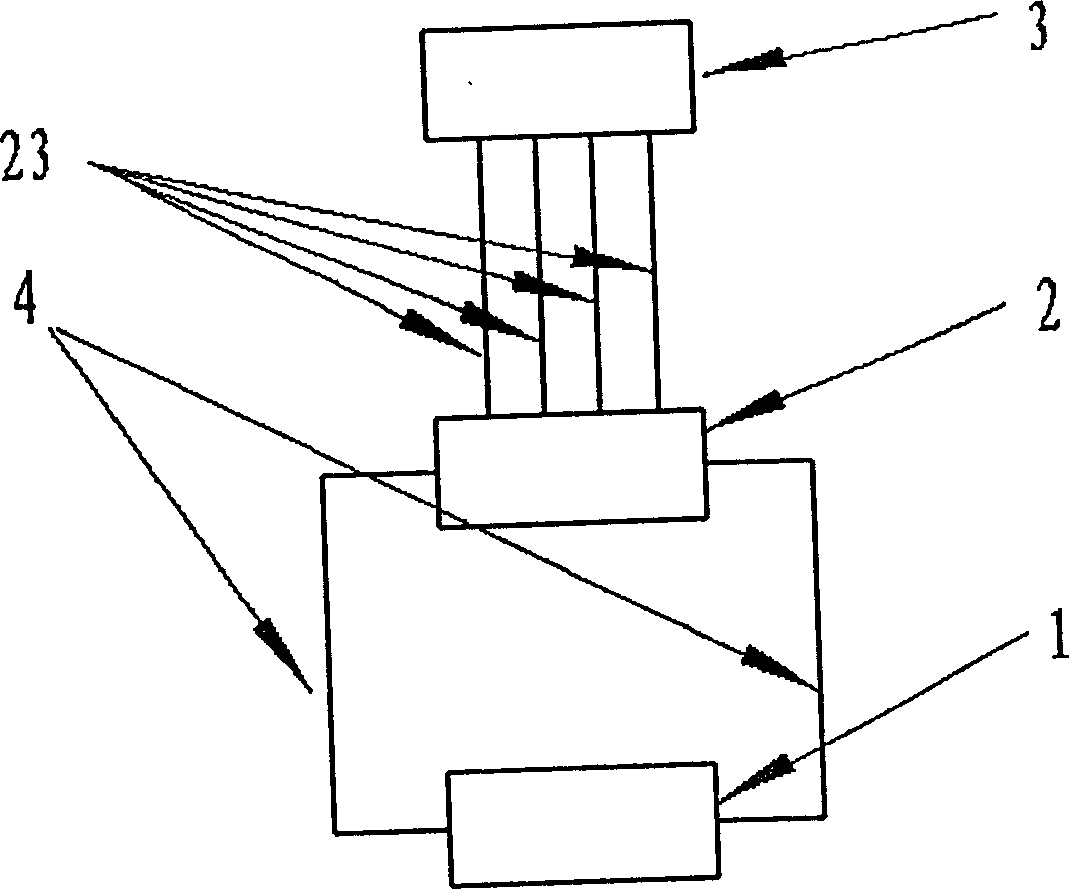

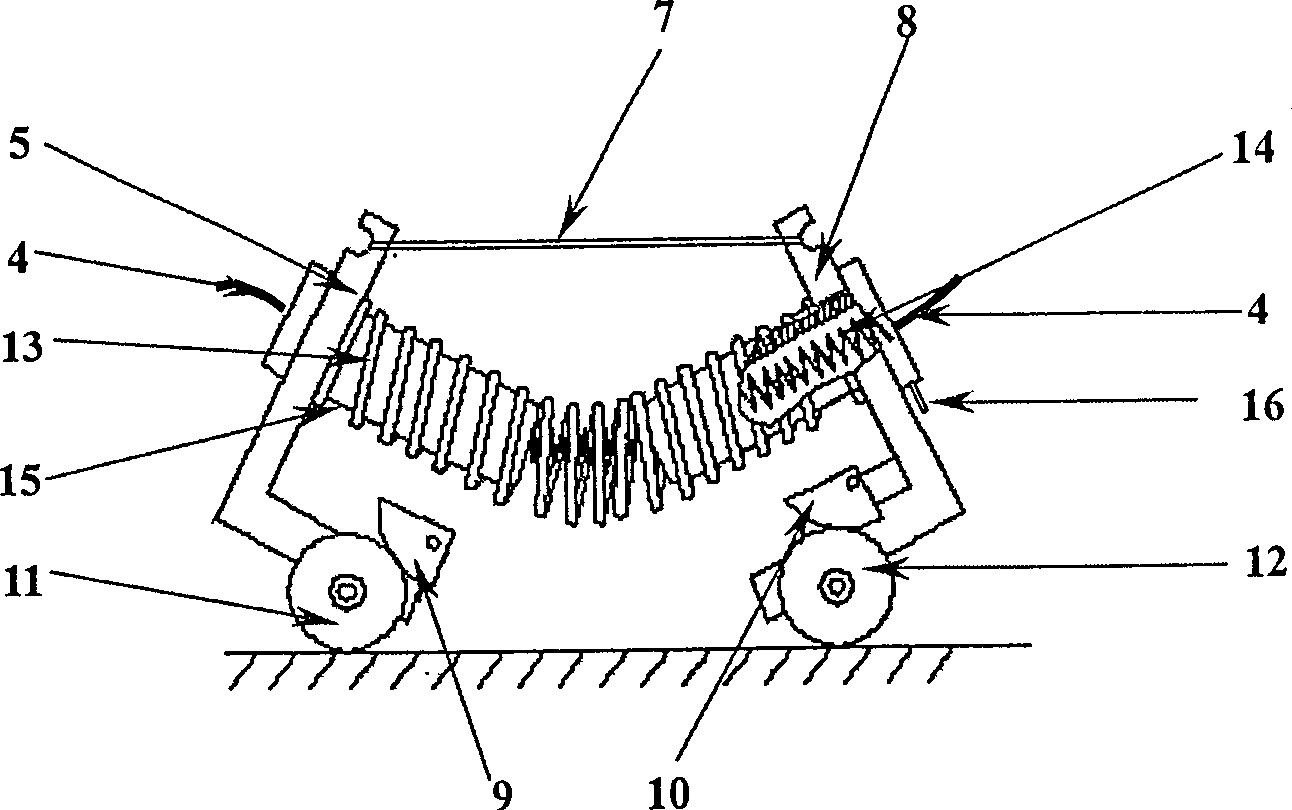

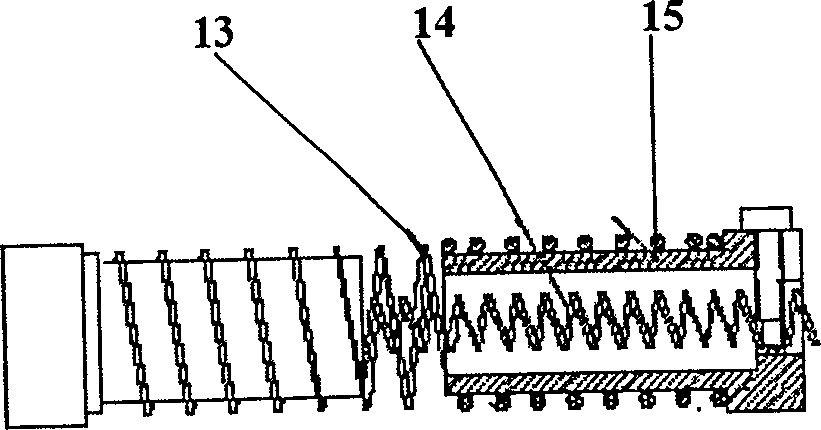

[0023] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention mainly includes: a mechanism body 1, a control system 2 and a power supply device 3, two output leads 4 of the control system 2 are connected to the mechanism body 1, four input leads 23 are connected to the power supply device 3, and the mechanism body 1 Mainly includes: front car body 5, shape memory alloy driver 6, elastic rod 7, rear car body 8, front wheel self-locking mechanism 9, rear wheel self-locking mechanism 10, front wheel 11 and rear wheel 12. The connection method is : The elastic rod 7 is hinged with the front car body 5 and the rear car body 8, the front car body 5 and the front wheel 11, the front car body 5 and the front wheel self-locking mechanism 9, the rear car body 8 and the rear wheel 12, and the rear car body 8 It is connected with the rear wheel self-locking mechanism 10 through the axles respectively. The shape memory alloy driver 6 is connected with the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com