Hub structure provided with reduction box

A reduction gearbox and hub technology, which is applied in the field of hub structures with reduction gearboxes, can solve the problems of small torque, inconvenient wheelchair users, and easy to cause danger, etc., and achieve the effect of increasing forward torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

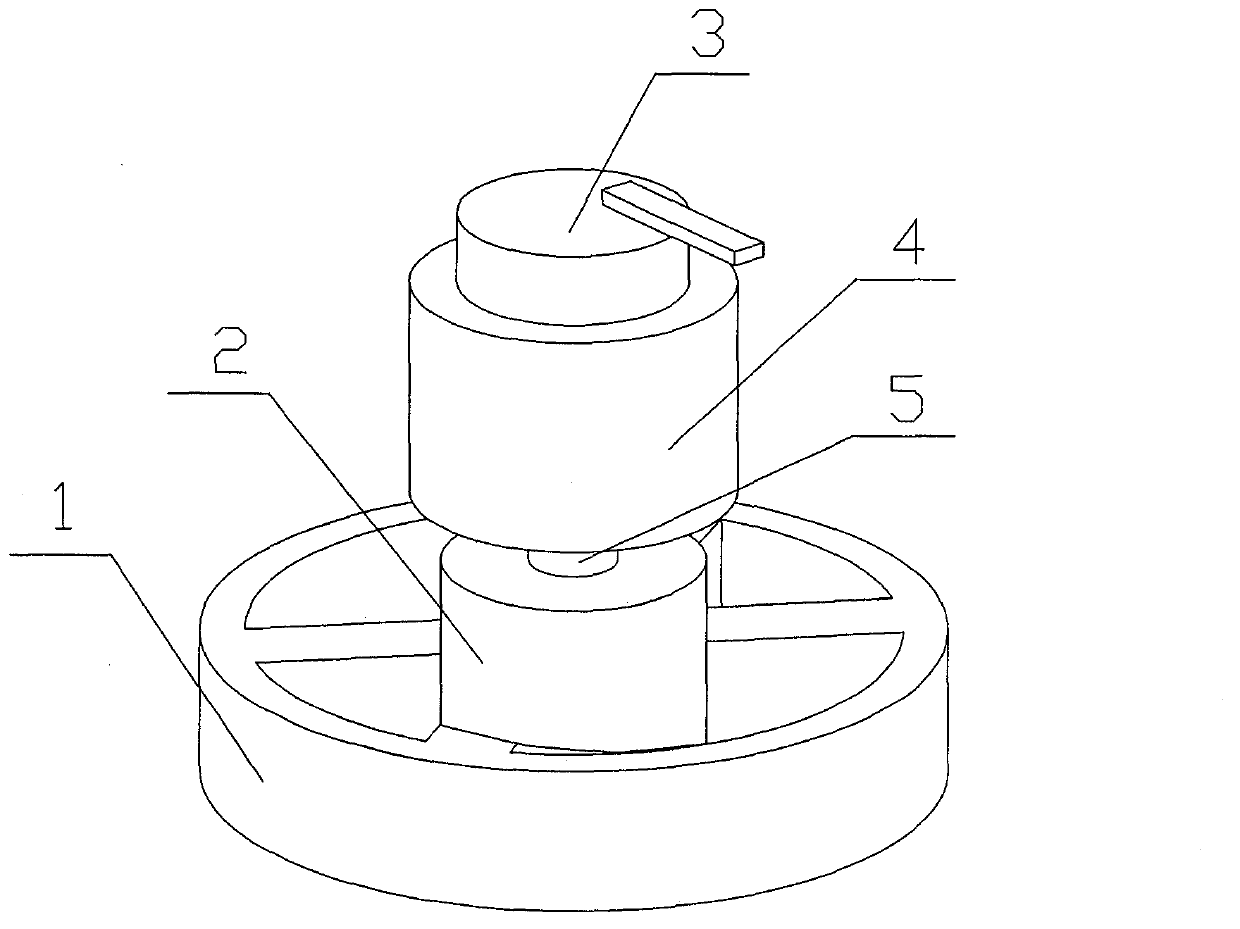

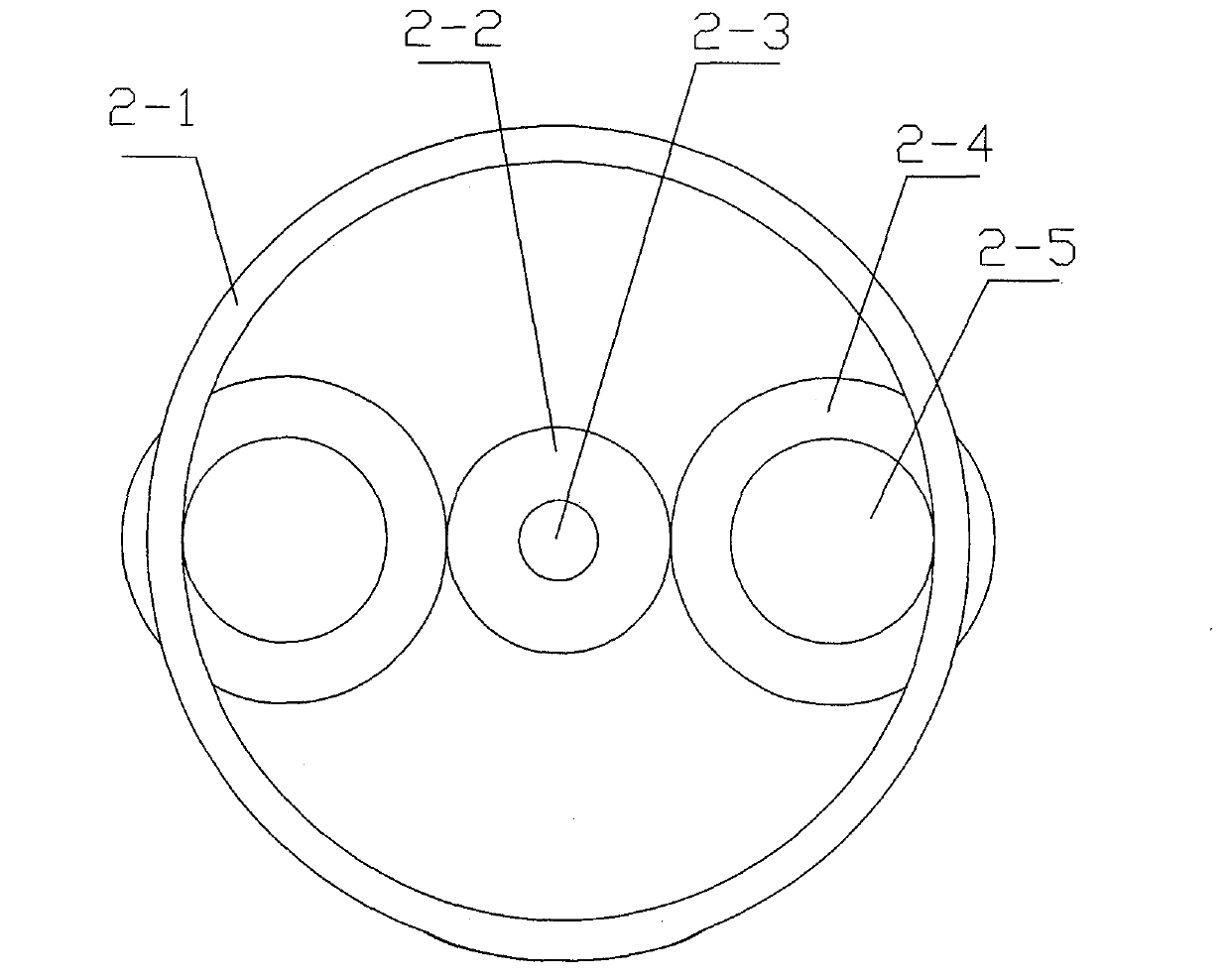

[0012] Such as figure 1 and figure 2 A hub structure with a reduction box is shown, including a hub 1, a motor 4 is provided at the axis of the hub 1, a braking device 3 is provided on one side of the motor 4, and a brake device 3 is provided between the motor shaft 5 and the hub 1. There is a reduction box 2; the reduction box 2 includes a gear shaft 2-3 connected with the motor shaft 5, and a sun gear 2-2 is arranged on the gear shaft 2-3, and the sun gear 2-2 is evenly connected with the reduction box 2. Two distributed planetary gears 2-4 are meshed, and a drive pinion 2-5 is arranged on the axis of the planetary gear 2-4, and the lower part of the drive pinion 2-5 is a pin shaft, which is fixedly inserted into the At the axis of the planetary gear 2-4, the drive pinion 2-5 meshes with the large ring gear 2-1.

[0013] The above planetary gears 2-4 are not limited to two, as long as there are more than two, it can be realized, and the uniform distribution can ensure tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com