Temp.-compensation type crystal oscillator and method for regulating its out-put frequency

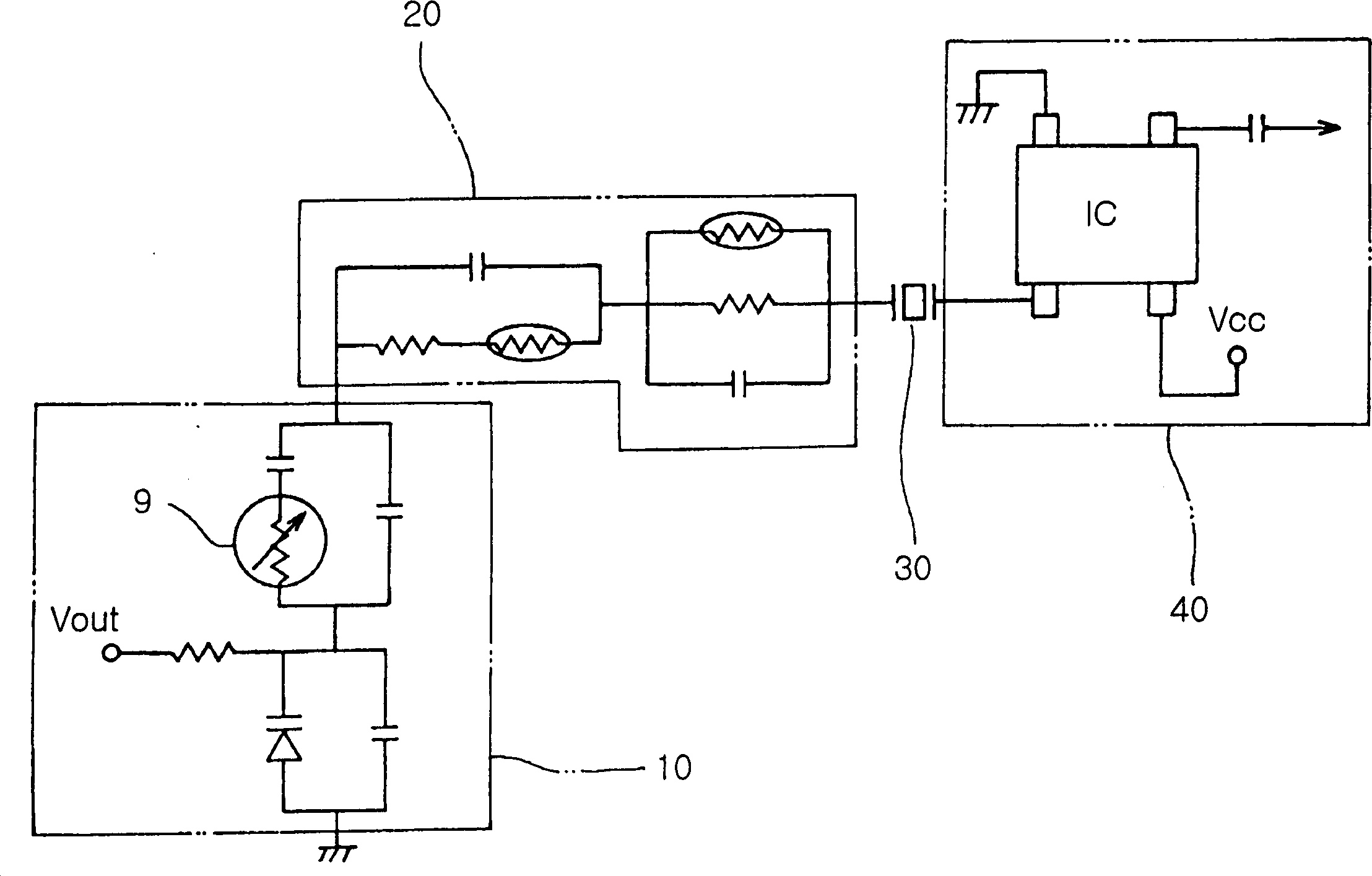

A technology for crystal oscillators and temperature compensation, applied in power oscillators, output stability, electrical components, etc., can solve problems such as increasing size and difficulty in miniaturizing mobile communication terminals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

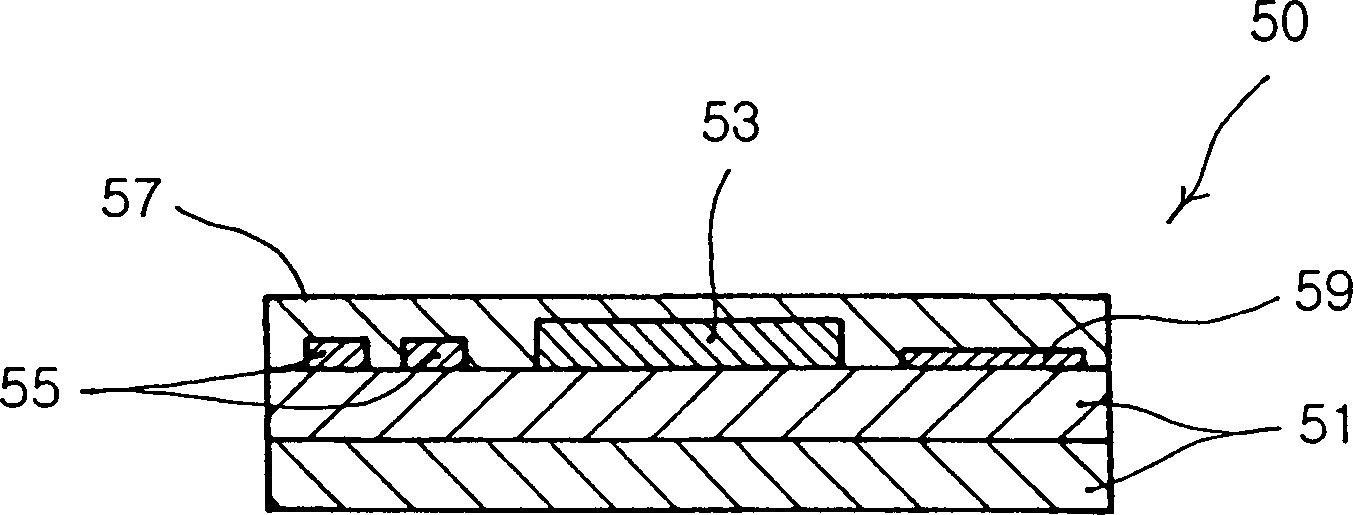

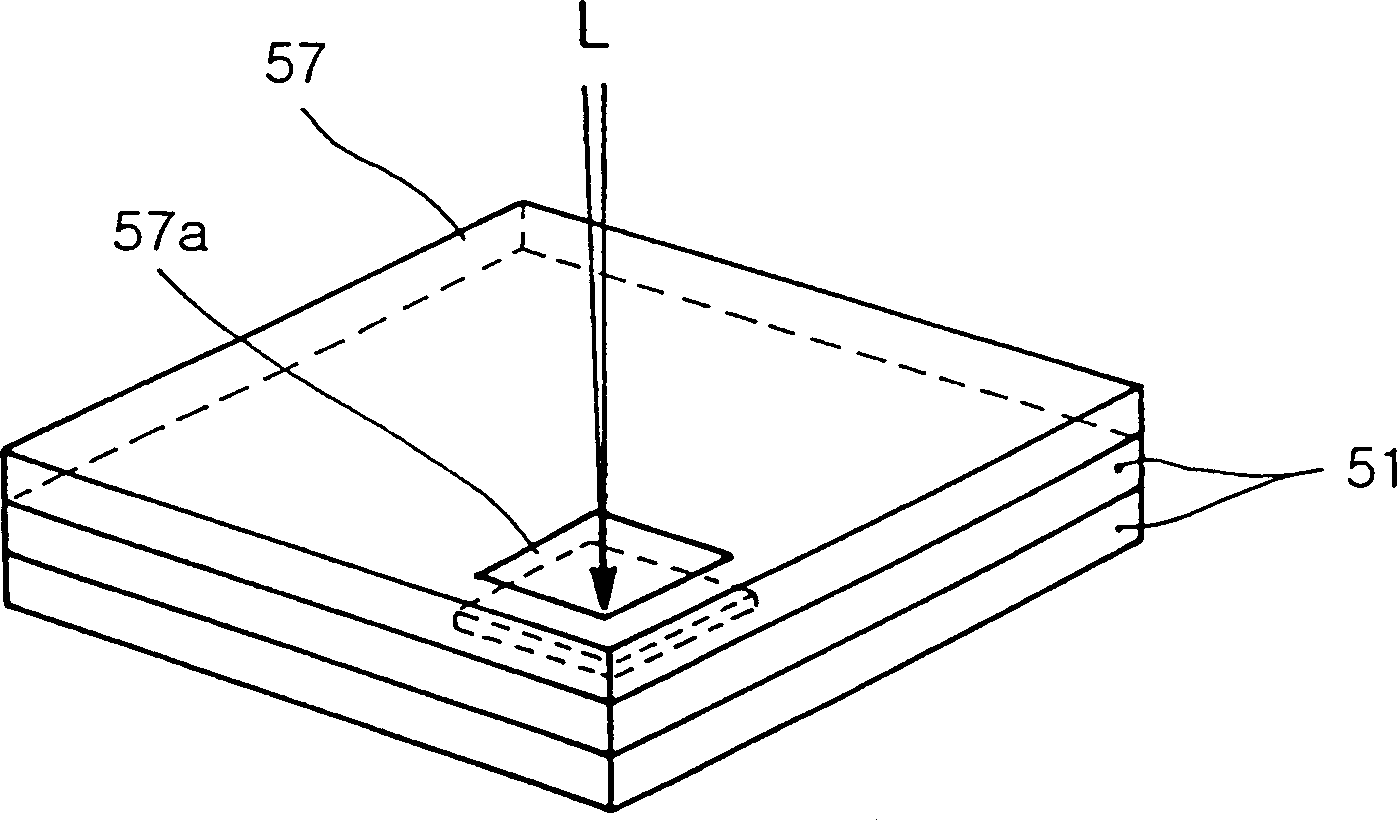

[0026] image 3 is a side sectional view of a temperature compensated crystal oscillator 100 according to a preferred embodiment of the present invention;

[0027] refer to image 3 The temperature compensated crystal oscillator 100 includes a top layer 101, on which a crystal oscillator unit 103 and components 105 constituting a temperature compensation circuit and an oscillator circuit are printed with conductive patterns. Here, the crystal oscillating unit 103 includes a crystal oscillating plate to generate an output frequency. The layered structure 101 consists of three layers 101a, 101b and 101c. In addition, the upper surface of the first layer 101 a on which the crystal oscillation unit 103 and the circuit components 105 are mounted is covered with a metal case 107 .

[0028] Such as image 3 As shown, the feature of the present invention is that the planar thin film resistor 109 is formed on the upper surface of the third layer 101c, and the third layer 101c is al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com