Fluid distribution end plate of aliform plank type heat exchanger and flow deflector connected end plate

A plate-fin heat exchanger and fluid distribution technology, applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc. efficiency and other issues to achieve the effect of eliminating poor heat transfer, reducing operation and maintenance costs, and improving heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

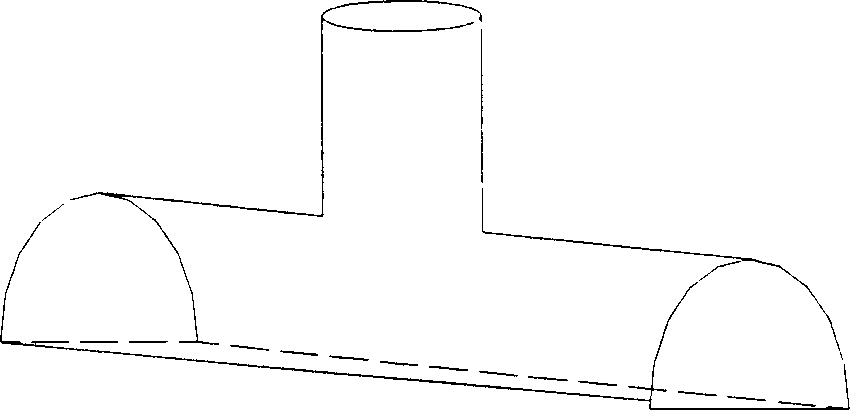

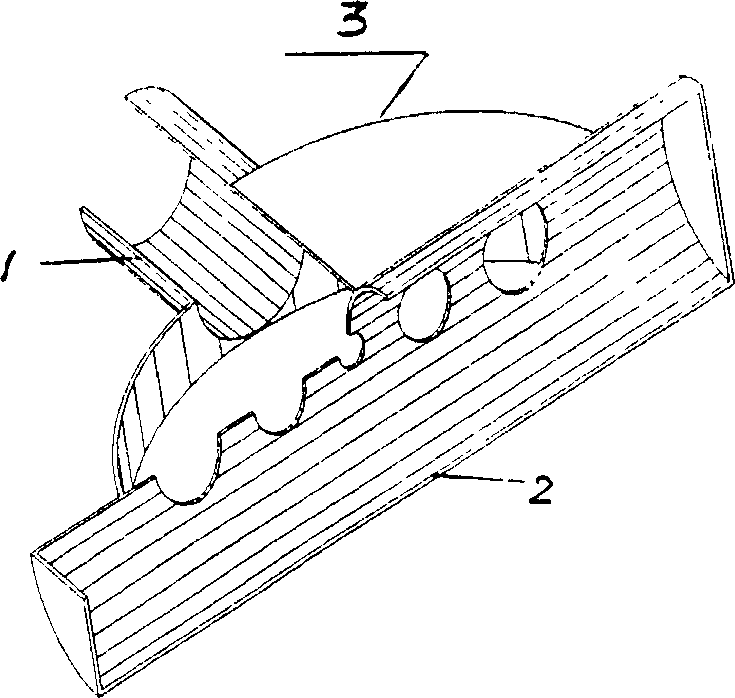

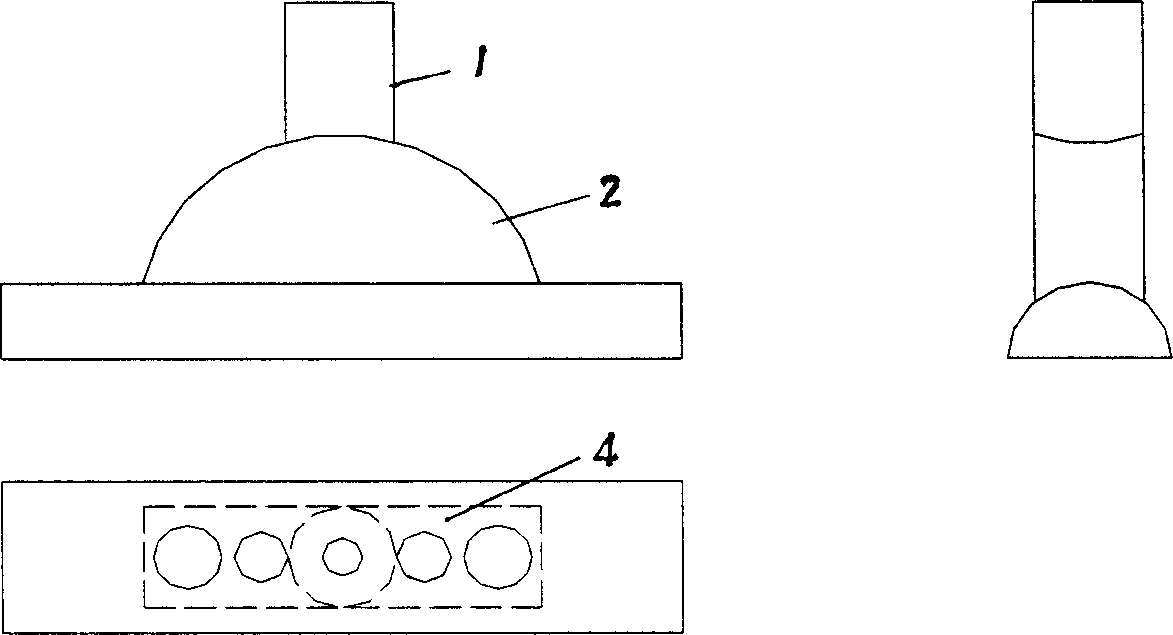

[0030] See attached picture. According to the technical solution of the present invention, the fluid distribution head of the plate-fin heat exchanger is still according to the traditional basic type head " "Type structure design, which includes a fluid inlet section 1 and an arc-shaped head connection section 2; an outer arc 3 is added between the fluid inlet section 1 and the head connection section 2 as a secondary head, and the head A plurality of through holes are distributed on the connecting section 2 .

[0031] There are 5 to 7 through holes distributed on the head connection section 2 .

[0032] The ratio of the equivalent sectional diameter of the outlet of the secondary head to the equivalent sectional diameter of the outlet of the primary head is equal to the ratio of the diameter of the inlet pipe to the equivalent sectional di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap