Electrostatic driver

A technology of electrostatic drive and driver, which is applied in the direction of fast-moving devices, electrostatic motors, electrostatic generators/motors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is directed to electrostatic driving devices. The electrostatic drive device embodiments described here can be used in a variety of devices, but have proven to be particularly beneficial for use in very small computer storage devices and other MEMS systems. For illustrative purposes only, the following embodiments of the electrostatic drive device will be discussed mainly in the context of high-density MEMS computer storage devices.

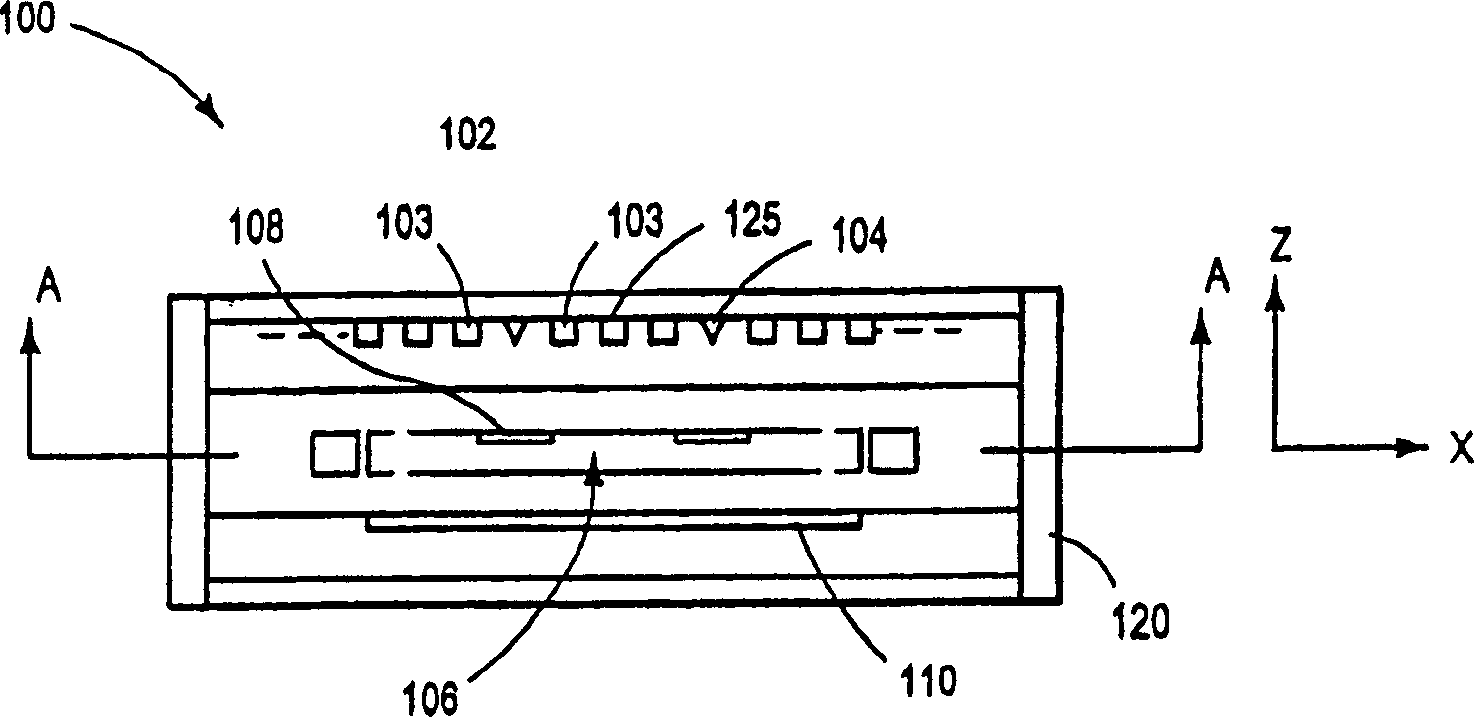

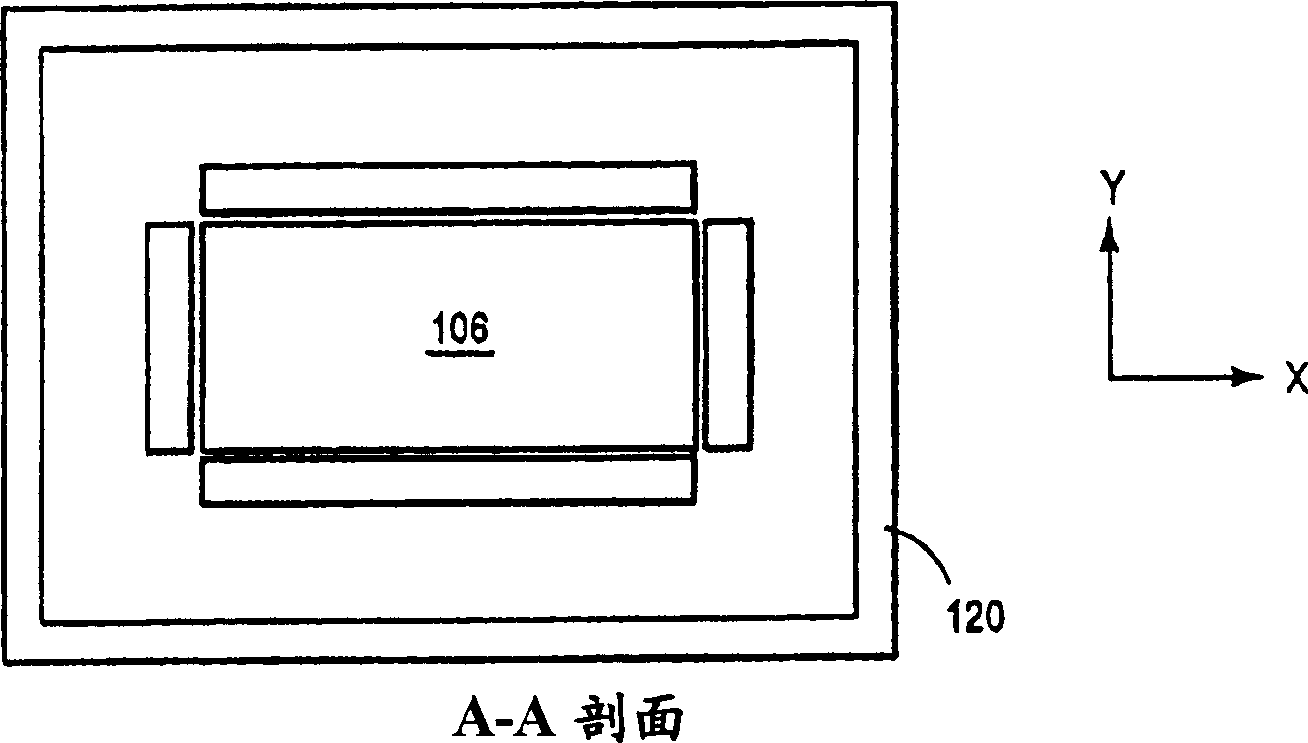

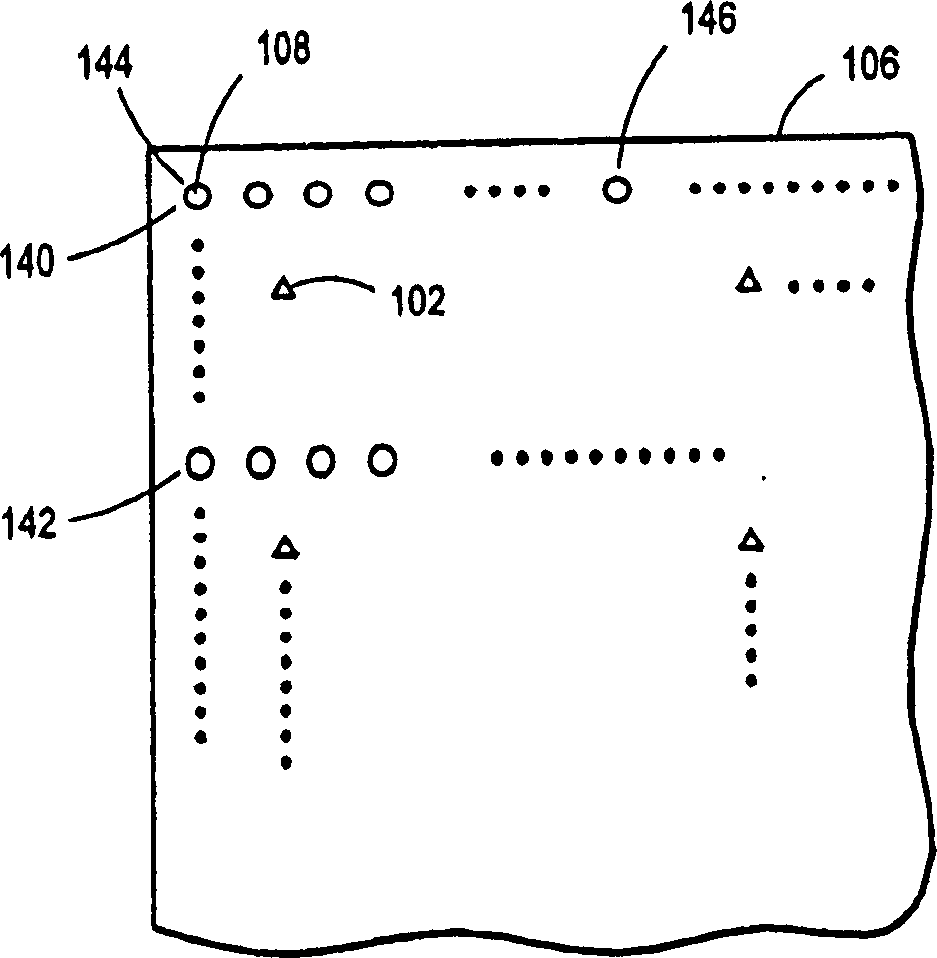

[0011] figure 1 with figure 2 The side and top cross-sectional views of the storage device 100 are respectively illustrated, in which the electrostatic drive device according to the present invention can be used. The storage device 100 includes: several field emitters, such as 102 and 104; a storage medium 106 with several storage areas such as 108; and a microactuator 110, which makes the storage medium 106 relative to the field Cause the emitter to scan (move) or vice versa. The storage device 100 may be configured s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com