Loom take-up motion

A technology of looms and cloth rolls, used in looms, textiles, winding strips, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

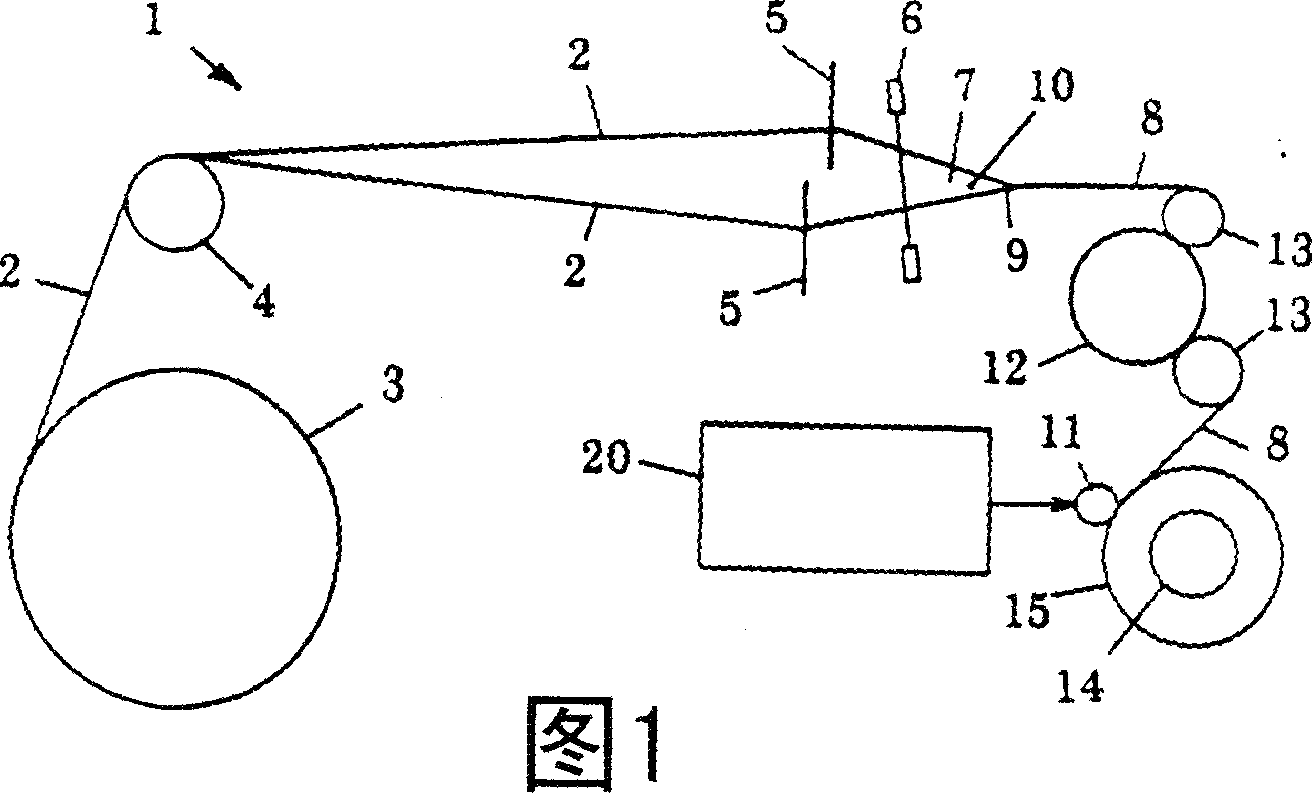

[0020] FIG. 1 shows the main part structure of a general loom 1 . In this FIG. 1 , the warp 2 is sent out in sheet form from the warp bundle 3 , passes through the support roller 4 and penetrates the heddle 5 and the reed 6 , forms an opening 7 and reaches the cloth fell 9 of the fabric 8 at the same time. On the other hand, after the weft thread 10 is weaved into the opening 7 of the upper and lower warp threads 2 and beats up, it is beaten into the cloth fell 9 of the fabric 8 by the reed 6 to form the fabric 8 . One side of the fabric 8 passes through the pressure roller 13, the floating yarn take-up roller 12, and the other side passes through the pressure roller 13 and the pressure roller 11 of the pressing part, and is wound into a cloth roll 15 on the outer circumference of the cloth winding roller 14.

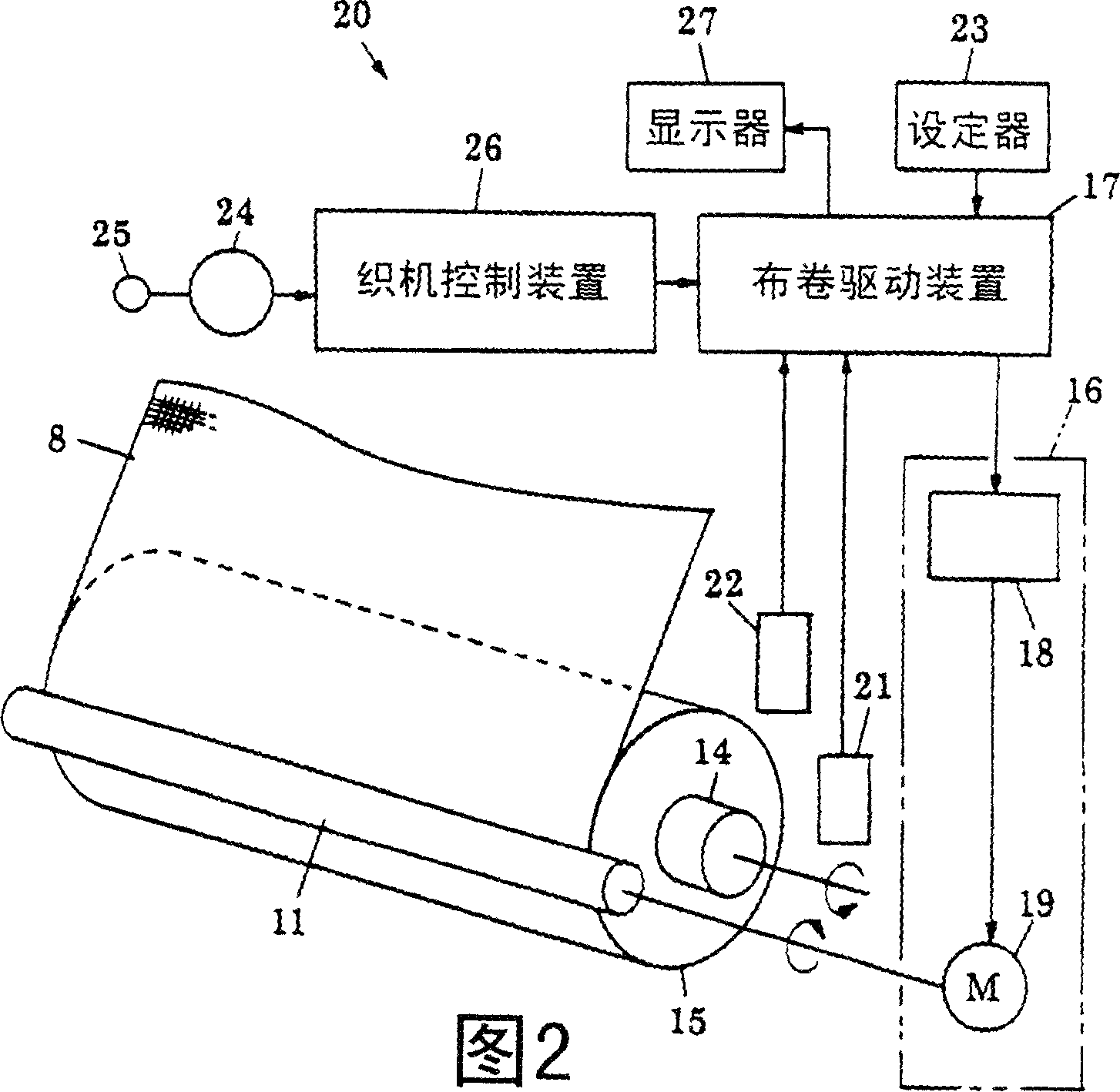

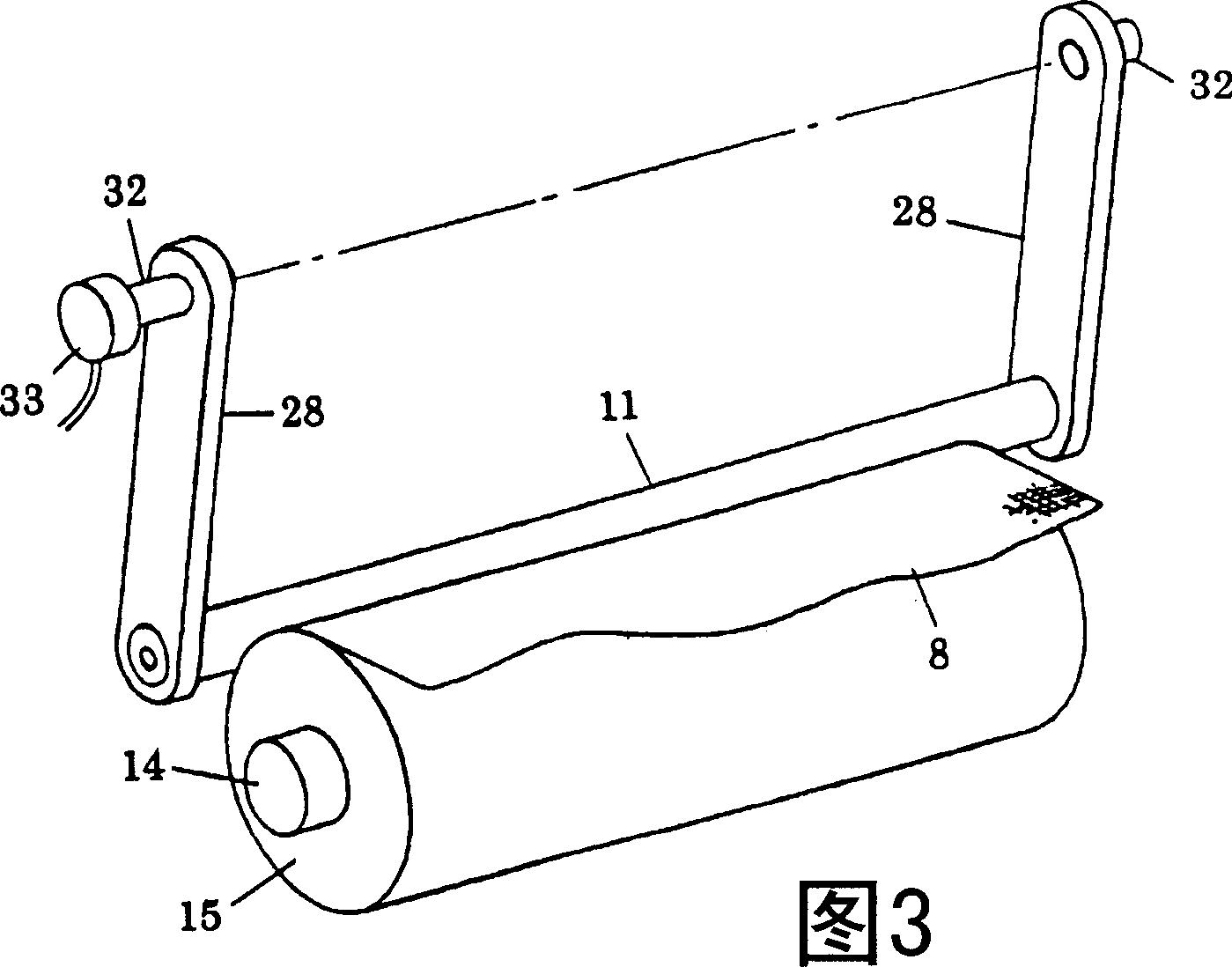

[0021] Moreover, the cloth roll 11 as a crimping member is extended in the width direction of the cloth roll 14, and is displaced according to the increase of the roll ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com