Ice maker heater controlling device

A control device and heater technology, which is applied in ice making, ice making, lighting and heating equipment, etc. It can solve the problems of inability to accurately control the heater, inability to remove ice normally, and inability of the temperature sensor to accurately sense the temperature of the ice making tank, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

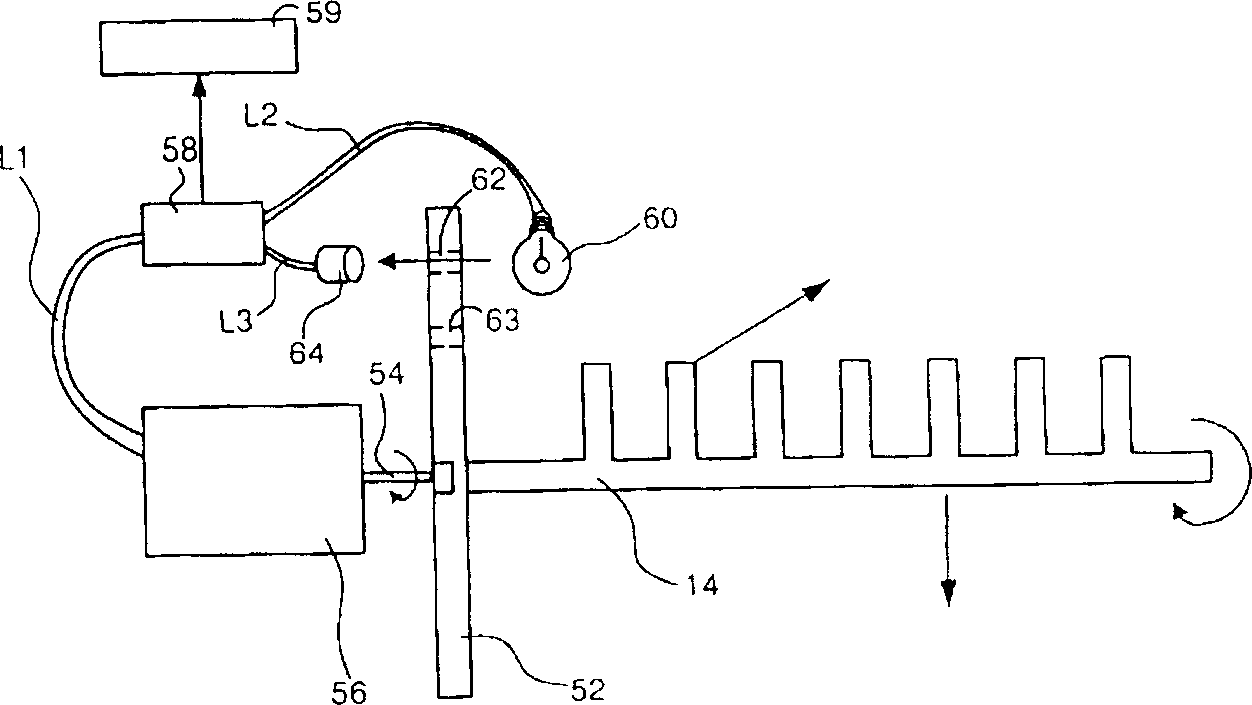

[0012] As previously mentioned, the activation of the heater 15 is carried out when the ice making process ends and the ice removal process begins, that is to say, the activation of the heater 15 means the beginning of the moving process, and the disconnection of the heater 15 means Ice removal is complete. Therefore, the control of the heater must be performed in conjunction with the ice removal process in the present invention.

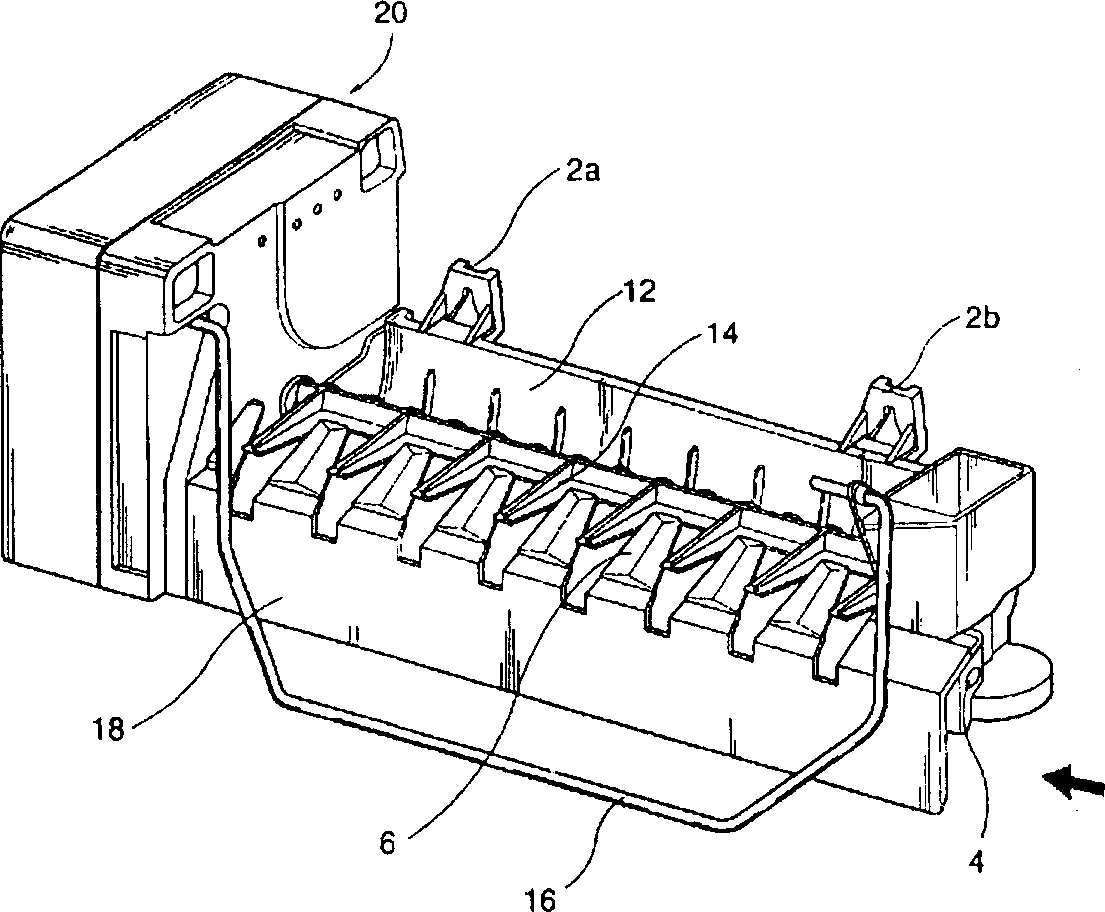

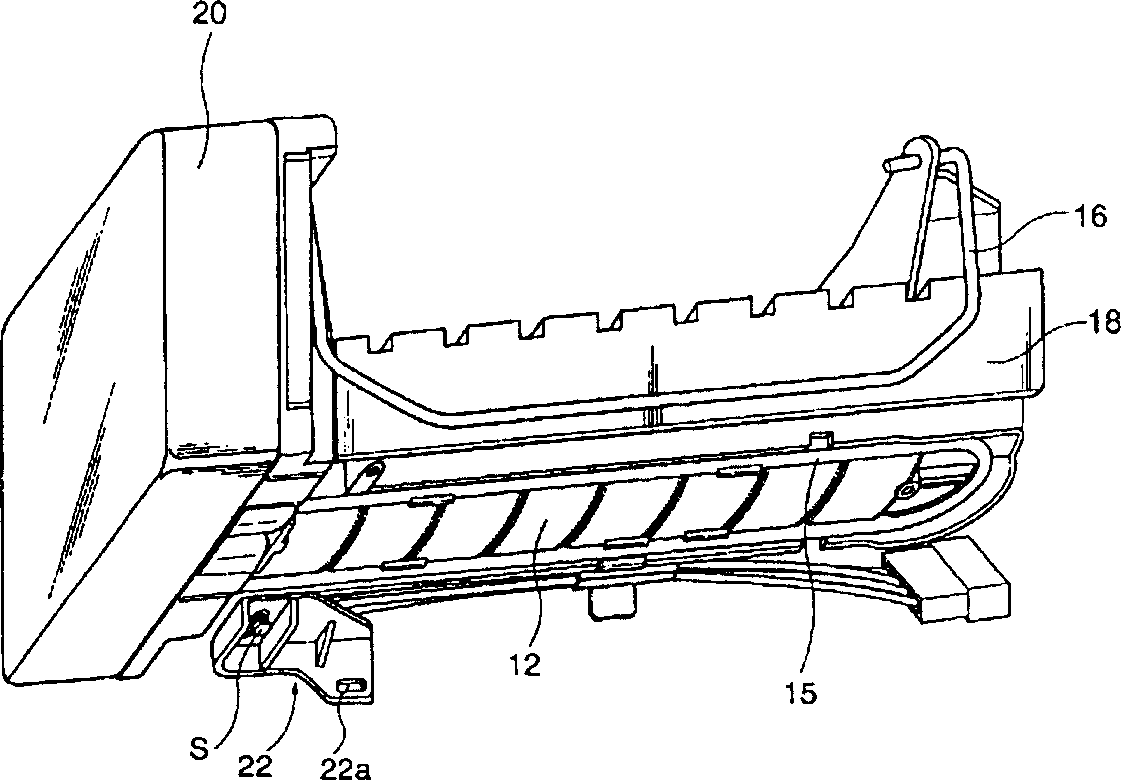

[0013] Such as Figure 3a , Figure 3b As shown, the heater control device of the ice maker of the present invention is mainly composed of a light shield 52 , a light sensor and a control unit 58 . The shading plate 52 is coaxially installed on the shaft end of the rotating shaft 54 of the ice-moving rod driving motor 56 with the ice-moving rod 14, so that it can be driven by the motor 56 to rotate synchronously. With the second light-transmitting hole 63, the rotation radius of the first light-transmitting hole 62 and the second light-transmit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com