New seal device for galvanized sheet

A technology of galvanized sheet and seal, which is applied in the direction of lifting device, printing, cleaning method and utensils, etc., can solve the problems of stamp demand, which can easily pollute the environment, affect the clarity of the seal, and cannot adjust the height of the galvanized sheet, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

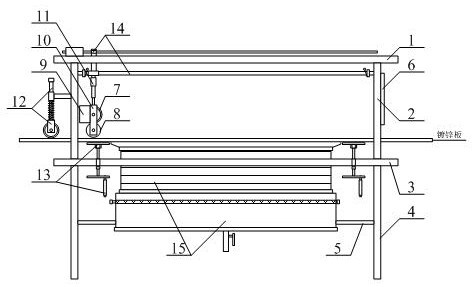

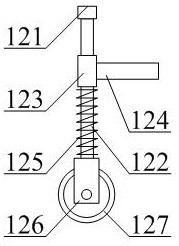

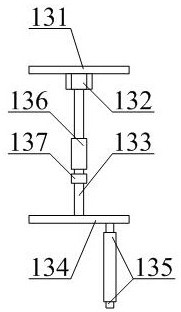

[0034] Below in conjunction with accompanying drawing, the present invention is described in detail, as shown in accompanying drawing 1 and accompanying drawing 2, a kind of novel stamp device for galvanized sheet, comprises return type crossbeam 1, return form support stand 2, frame 3, support leg 4. Connecting seat 5, control panel 6, dip roller 7, stamp roller 8, paint box 9, inverted U-shaped bracket 10, automatic push rod 11, buffer type galvanized sheet surface dust cleaning wheel structure 12, galvanized Plate seal height position adjustment strut structure 13, seal position movement adjustment machine structure 14 and seal paint leftover collection and filtration anti-fouling box structure 15, the return-shaped crossbeam 1 transverse bolts are connected between the return-shaped support stands 2 The upper end of the upper end of the support stand 2 is bolted to the upper left and right sides of the frame 3; the four corners of the bottom of the frame 3 are longitudinally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com