Optical fiber

A technology of optical fiber and fiber core, applied in cladding optical fiber, optics, light guide, etc., to achieve the effect of low loss characteristics, high-speed and high-quality optical data transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

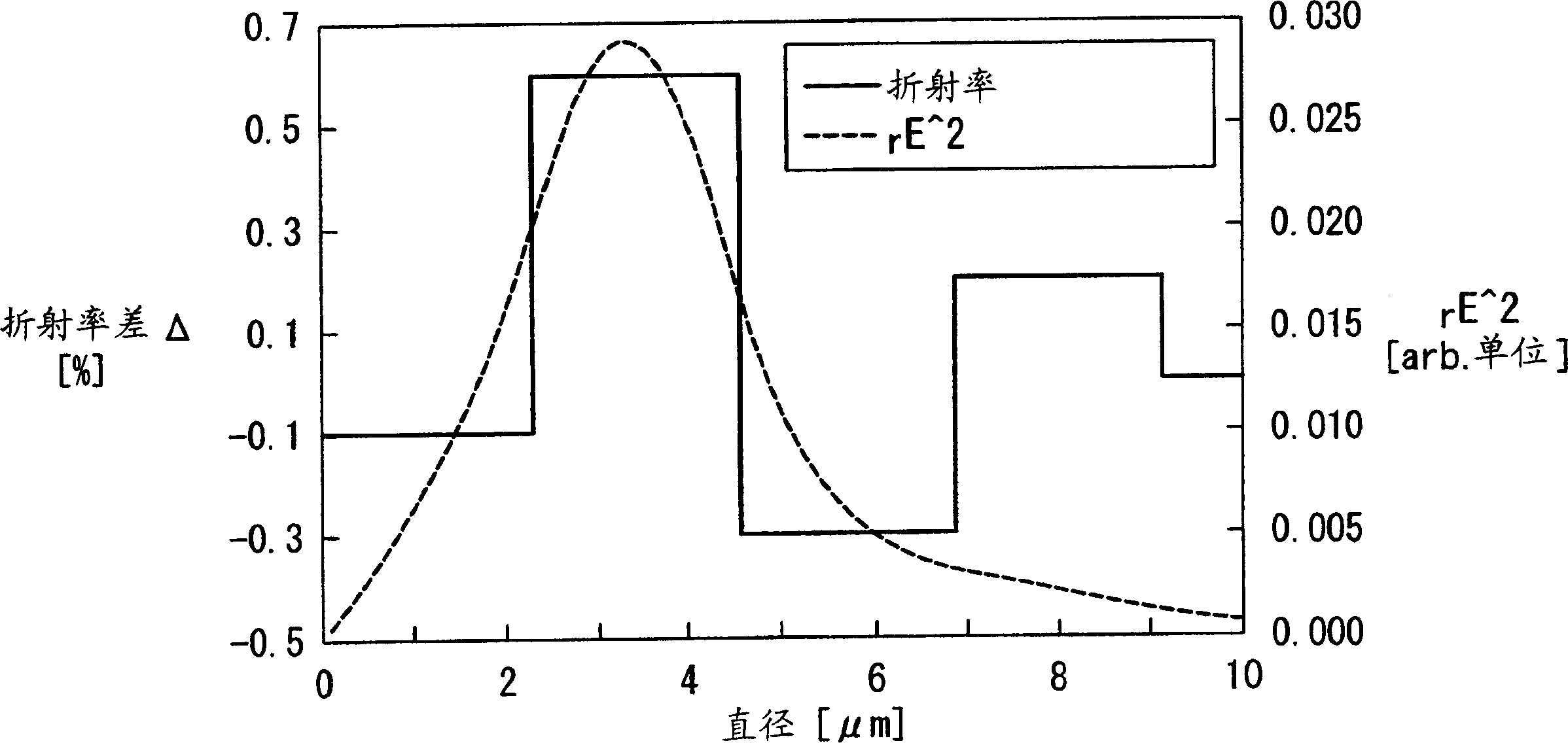

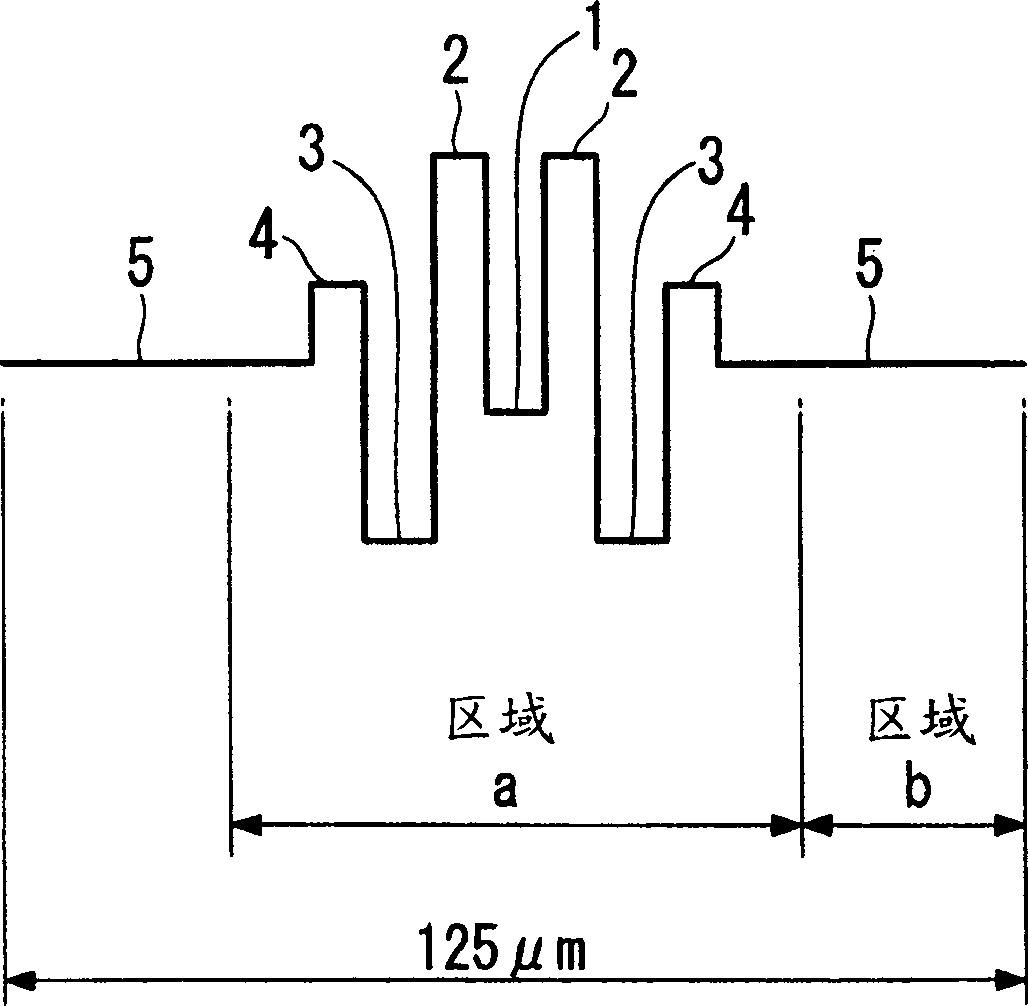

[0067] has produced a figure 1 Fiber with refractive index profile shown. This optical fiber is manufactured by using chemical vapor deposition (hereinafter referred to as CVD) method to produce figure 2 The region (a) in the optical fiber with the shown refractive index profile, this region (a) contains the core; figure 2 The region (b) in the fiber of the shown refractive index profile, this region (b) contains the cladding. attached here figure 2 As shown, the outer diameter of the fiber cladding is 125 μm. The chromatic dispersion at the wavelength of 1550nm in this fiber is +8ps / nm / km, which meets the requirements of product design. The properties of this fiber are shown in Table 2.

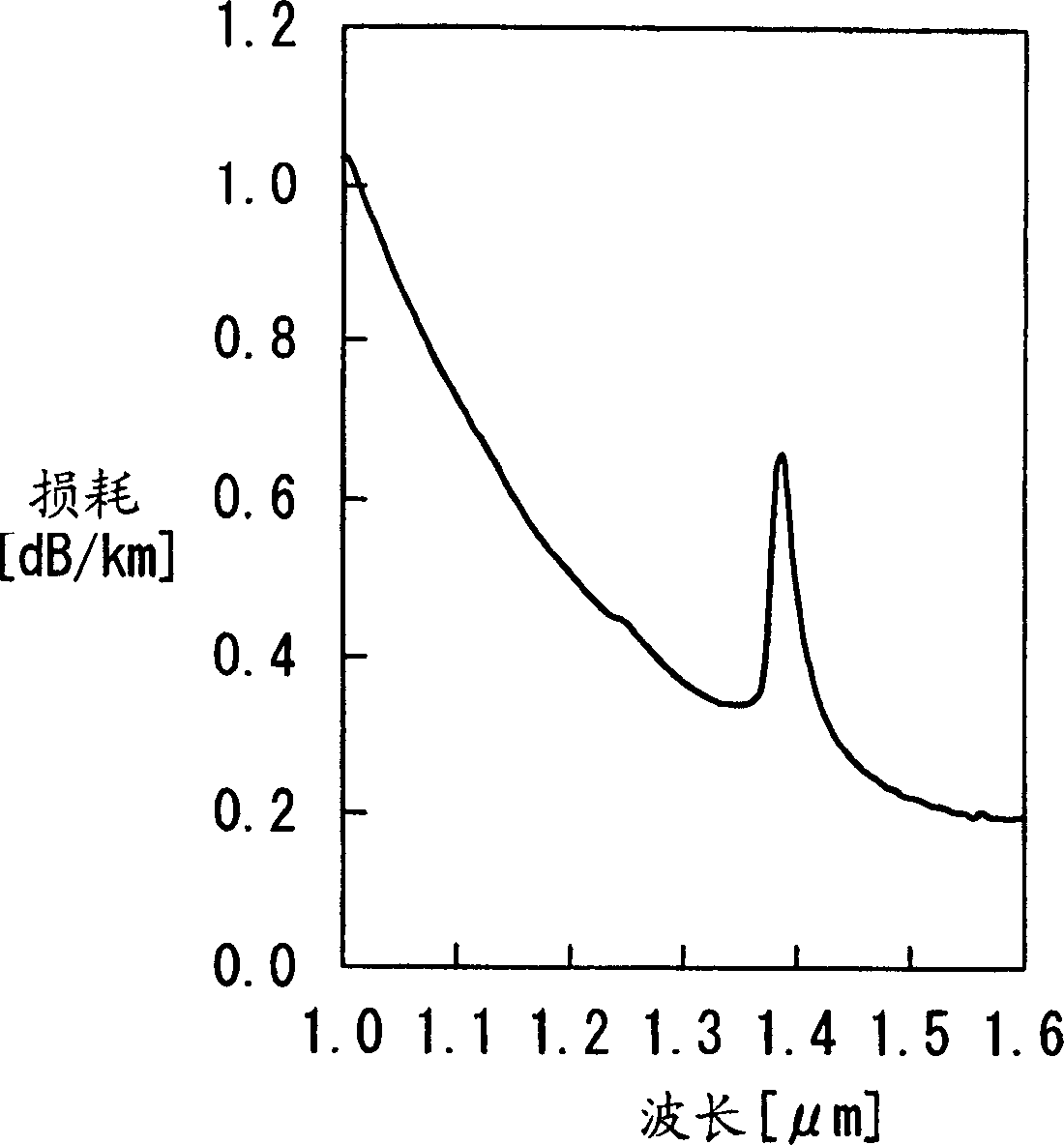

[0068] transmission loss

[dB / km]

0.206

Cable cut-off wavelength λcc

[nm]

1450

Effective core cross-sectional area A eff

[μm 2 ]

100.6

Mode Field Diameter MFD

[μm]

9.26

Dispersion

[ps / nm / km]

8.0

...

no. 2 approach

[0074] has produced a Figure 5 , 6 Fiber with refractive index profile shown.

[0075] attached Figure 5 Design values of the refractive index profile in the general NZ-DSF dispersion region are shown. attached Image 6Design values of the refractive index distribution are shown when the dispersion is set to about +9 ps / nm / km higher than the dispersion of the ordinary NZ-DSF. This optical fiber is manufactured by using chemical vapor deposition (hereinafter referred to as CVD) method to produce figure 2 The region (a) in the optical fiber with the shown refractive index profile, this region (a) contains the core; figure 2 The region (b) in the fiber of the shown refractive index profile, this region (b) contains the cladding. attached here figure 2 As shown in , the outer diameter of the cladding in the fiber was produced to be 125 μm.

[0076] In this fiber example, the MRIP can be reduced from 0.50 to 0.43 by increasing the dispersion to about +9 ps / nm / km. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com