Sealing type prothole window for front-loading drum washing machine

A drum washing machine, sealed technology, applied to other washing machines, applications, washing devices, etc., can solve the problems of tearing of laundry, overloading, endangering the firmness of the glass plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] figure 1 It shows a front view of a washing machine 1 provided with an open sealed round window 2 for closing the loading and unloading opening 3 .

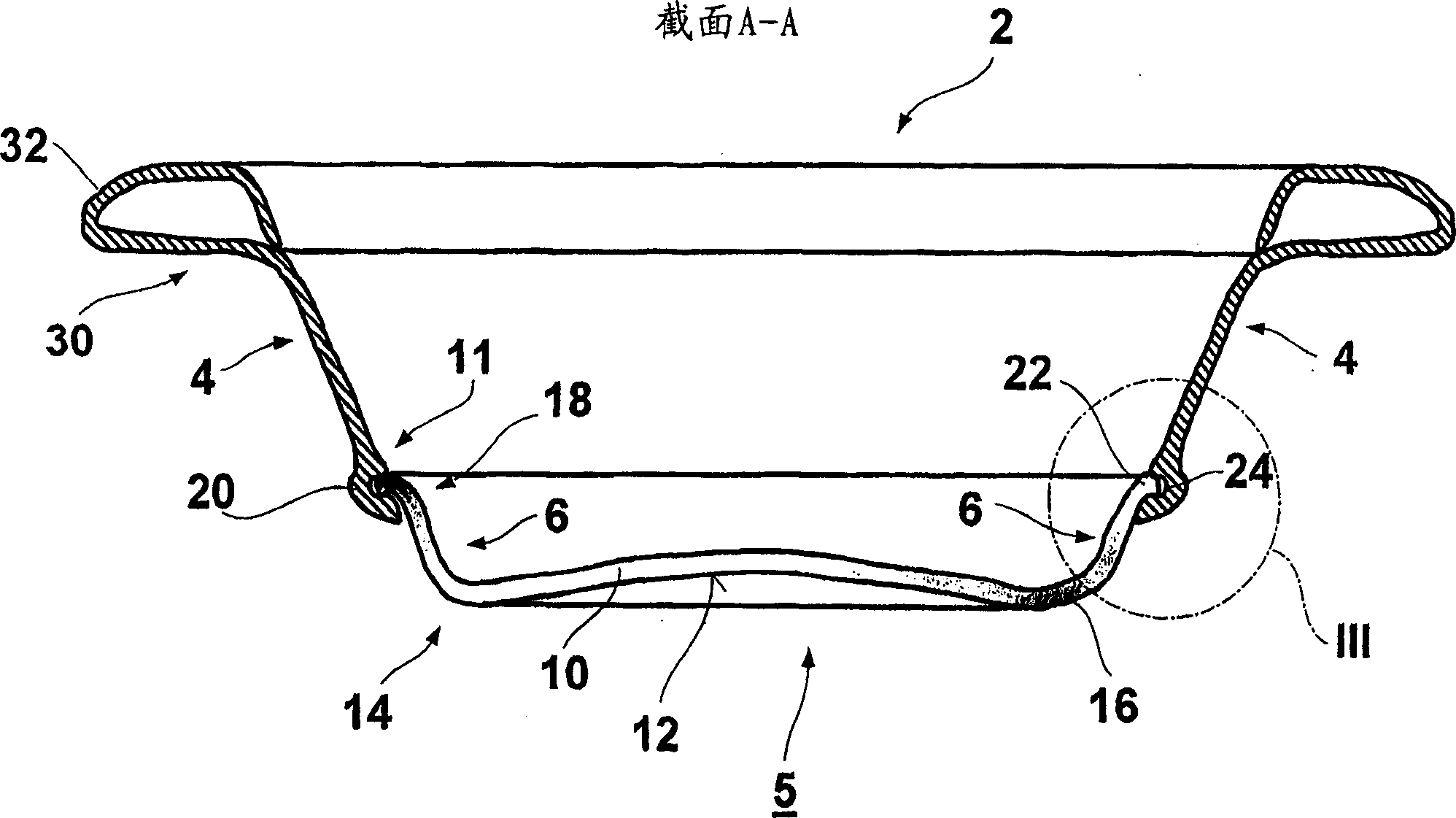

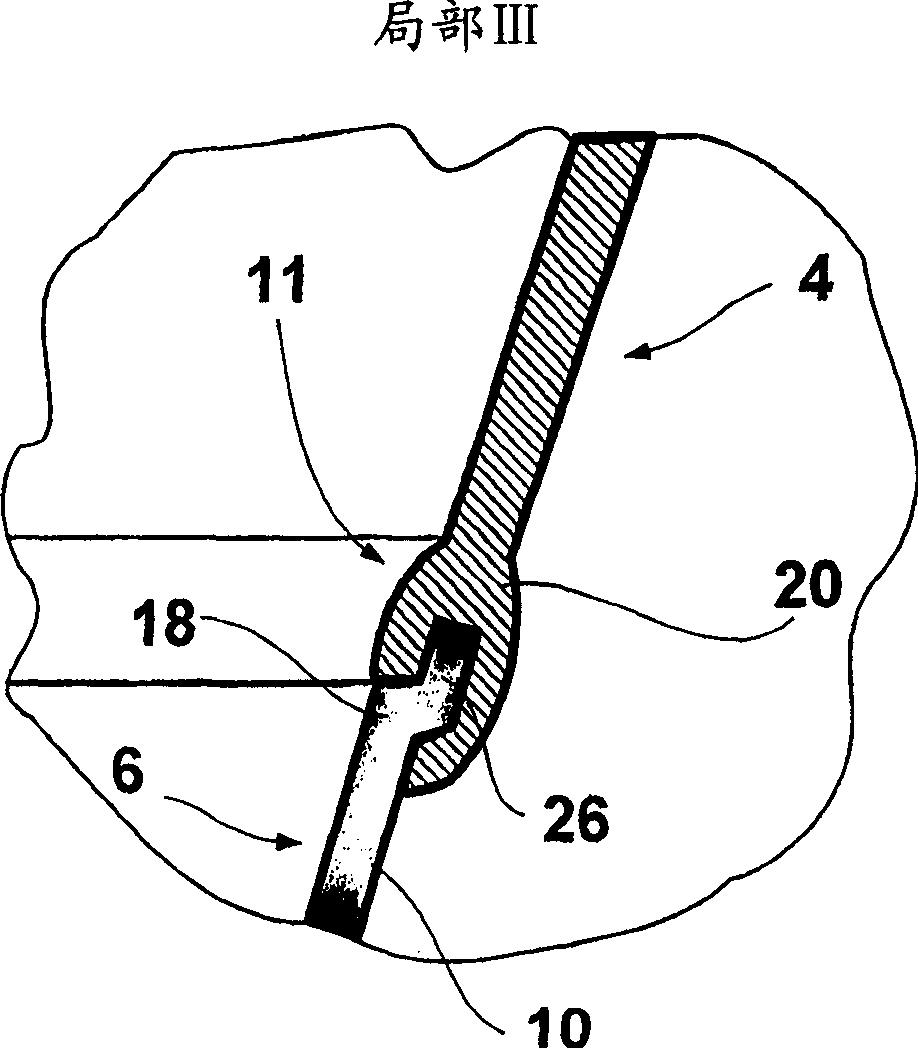

[0019] figure 2 A preferred embodiment of the sealed round window 2 of the present invention is shown. The sealed round window 2 consists of a side wall 4 made of hard plastic and a base 5 made of mineral glass. The sight glass 10 has an inner surface 12 slightly raised toward the mouth of the cup. In the edge region 14 of the base 5 the sight glass 10 is bent towards the side wall 4 in such a way that a rounded glass shoulder 16 is formed. On the outer edge of the glass shoulder 16 , the sight glass 10 has a ring-shaped connecting portion 6 which runs obliquely relative to the inner surface 12 of the base 5 . The connecting part 6 opens into a top end 18 which has an annular projection 22 extending substantially parallel to the inner surface 12 of the bottom 5 .

[0020] The projection 22 engages in the top end 20 o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap