Goods sorting method of material flow center

A logistics center and logistics technology, applied in special data processing applications, instruments, electronic digital data processing, etc., can solve problems such as different basis, disunity, and insufficient replenishment of goods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

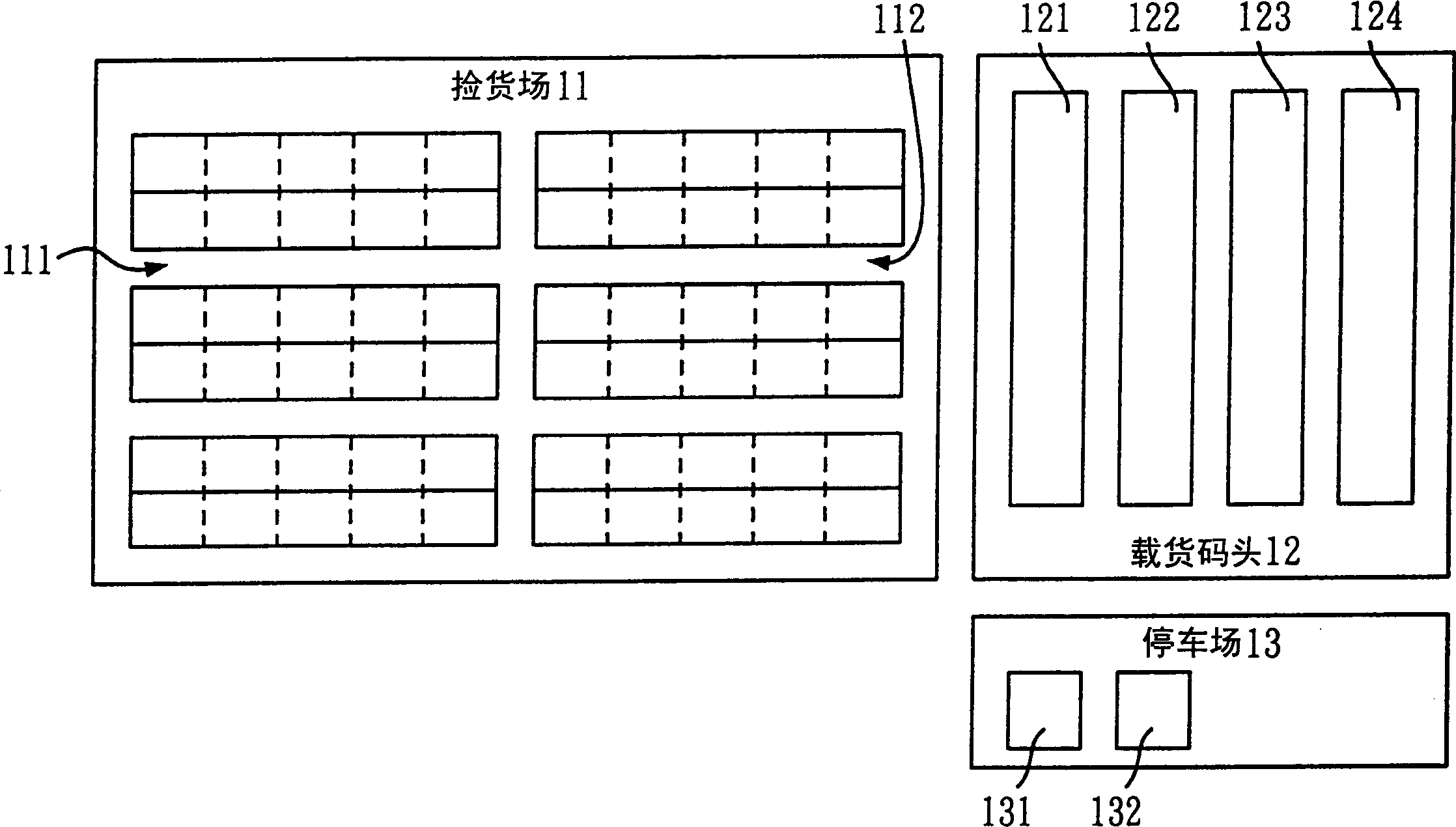

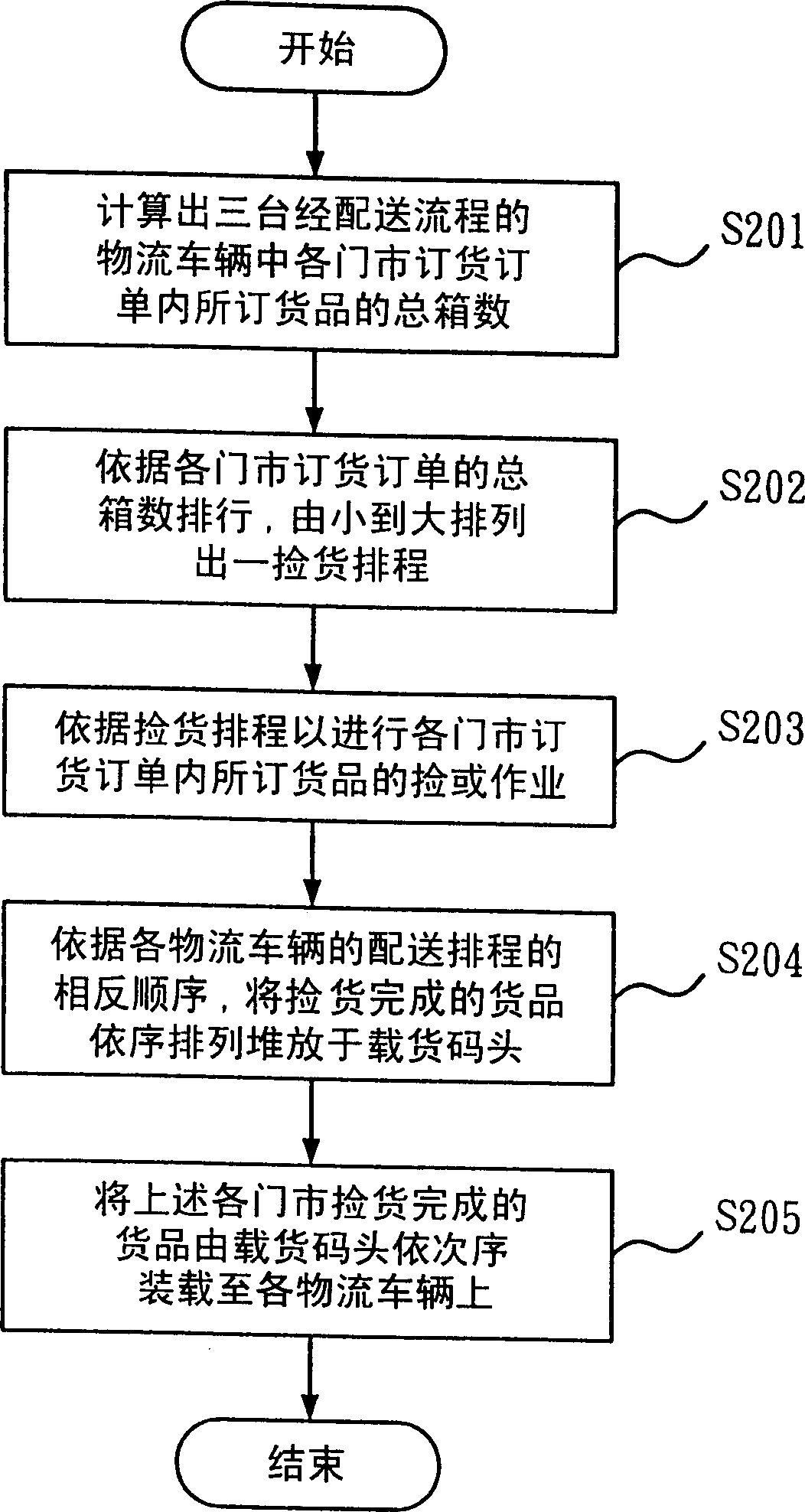

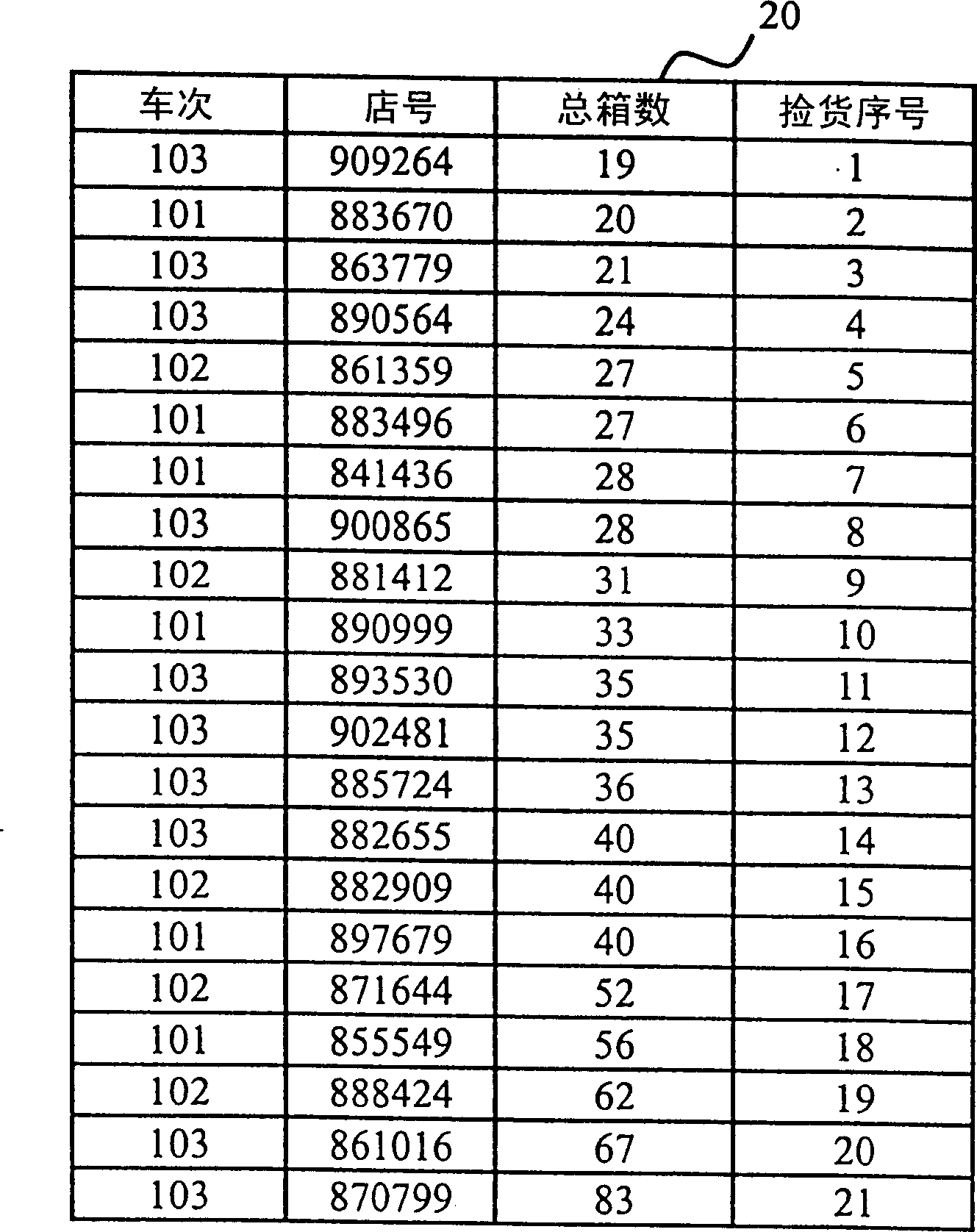

[0035] see figure 1 The configuration diagram of the logistics center, in this example, is applied to a logistics center, which is responsible for processing orders from chain convenience store stores, and is used to pick orders from multiple stores. A distribution center (Distribution Center, DC) in this example includes a picking yard 11 , a loading dock 12 , and a parking lot 13 . The picking yard 11 has a plurality of shelves to form a plurality of storage positions for storing various kinds of goods. There are picking lanes 111 and 112 between the shelves and the shelves, which can be used by replenishment personnel to use stackers for replenishment, and also It can be used for picking personnel to shuttle through it to carry out picking operations. For example, the first picker can enter the picking aisle 111 to pick goods first. At this time, other pickers who need to replenish goods in the picking aisle 111 must wait at the entrance; when the first picker finishes pic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com