Lub grease tube for verticle thrust bearing of open-end spinning cup

A technology of thrust bearings and air spinning, which is applied in the direction of rotating bearings, bearings, spinning machines, etc., and can solve the problems of narrow space and high transformation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

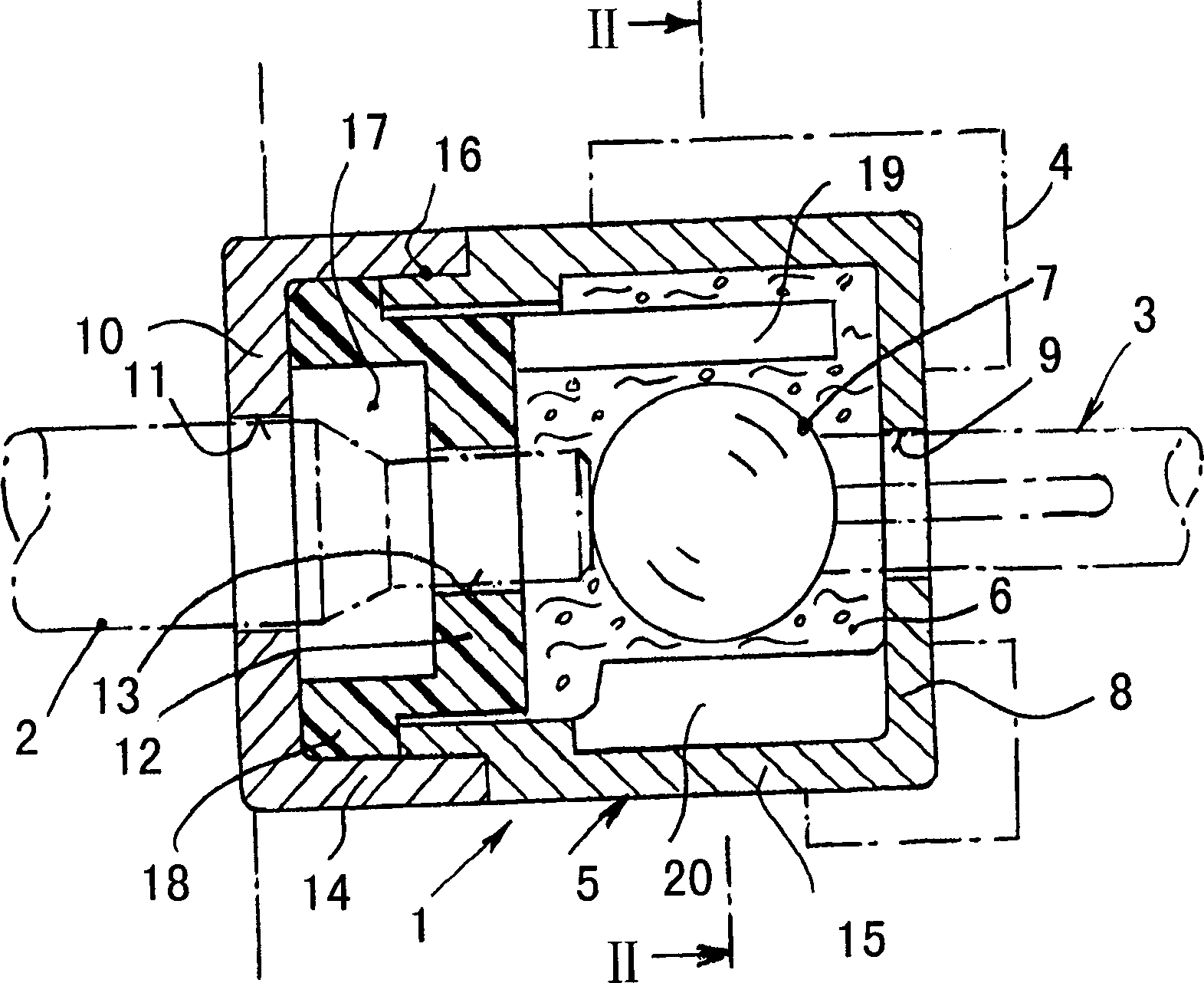

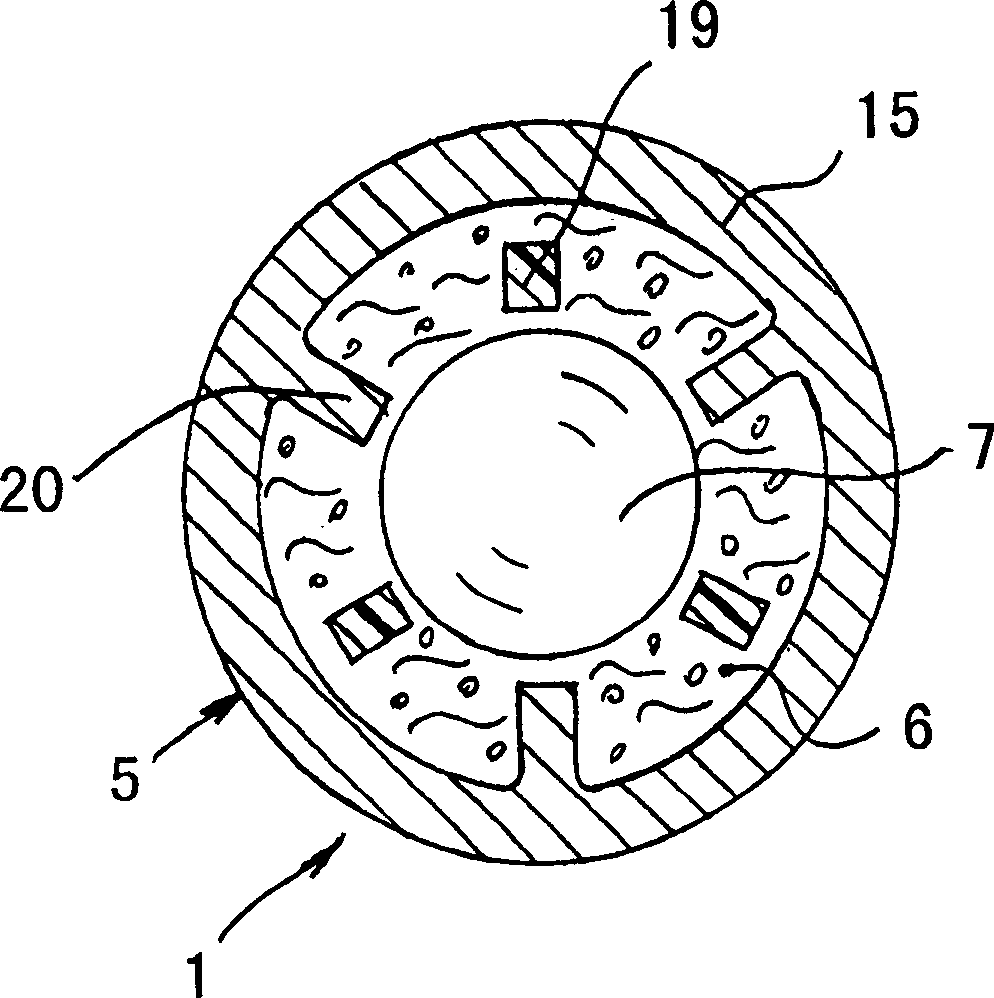

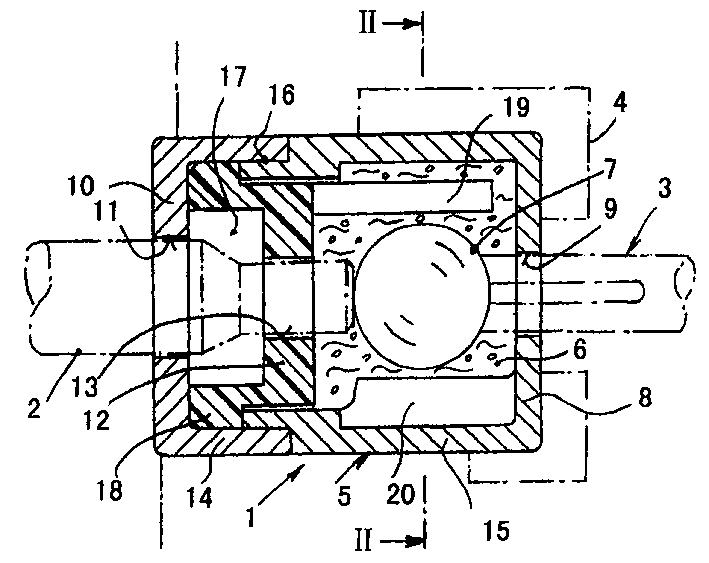

[0012] figure 1 and figure 2 The shown grease cartridge 1 is specially designed for a vertical thrust bearing of an open-end spinning rotor, of which there are several in an open-end spinning machine. In addition to the grease cartridge 1 shown, a cooperating rotor shaft 2 and a thrust bearing 3 as well as a bracket device 4 for clamping the grease cartridge 1 are indicated by dotted lines.

[0013] The grease cartridge 1 comprises a substantially cylindrical housing 5 with a grease chamber 6 containing grease. There is a thrust bearing ball 7 installed in the grease chamber 6, the ball is originally a part of the grease cylinder, when the rotor shaft 2 is running, it is supported by the ball, and the thrust bearing ball 7 itself is supported by the bolt type opening. Grooved thrust bearing 3 supports.

[0014] The housing 5 has a rear face wall 8 which provides a passage opening 9 for the screw-type thrust bearing 3 . Arranged on the front side of the grease cartridge 1 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap