Prosthetic mitral heart valve

A technology for heart valves and mitral valves, applied in the direction of heart valves, etc., can solve problems such as turbulent flow that cannot be completely avoided

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

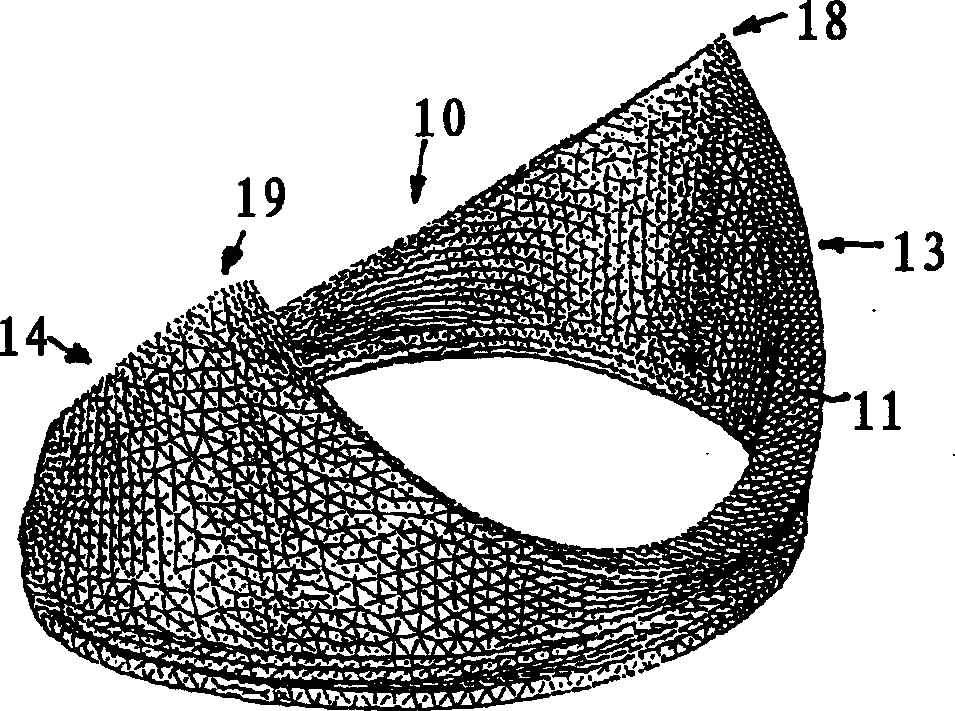

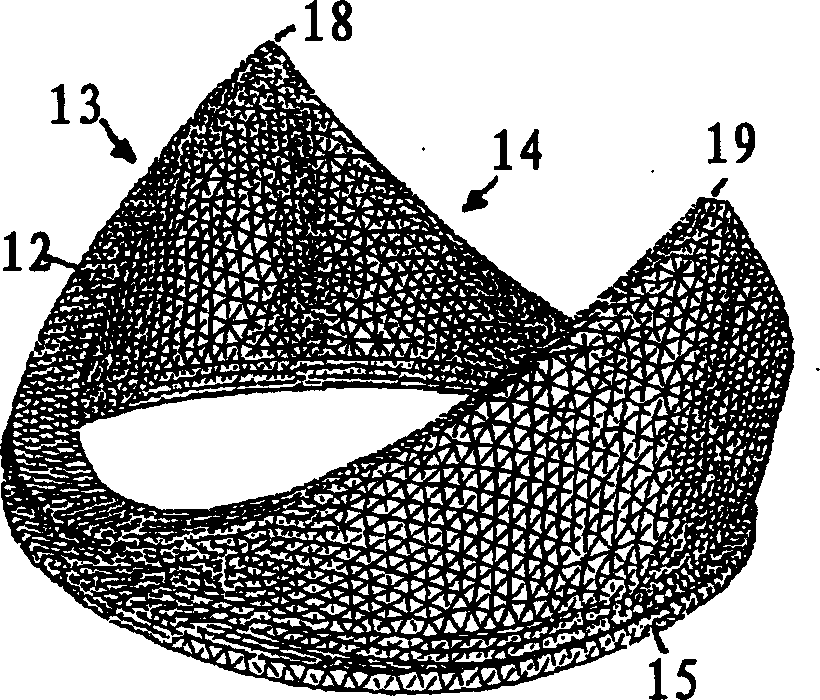

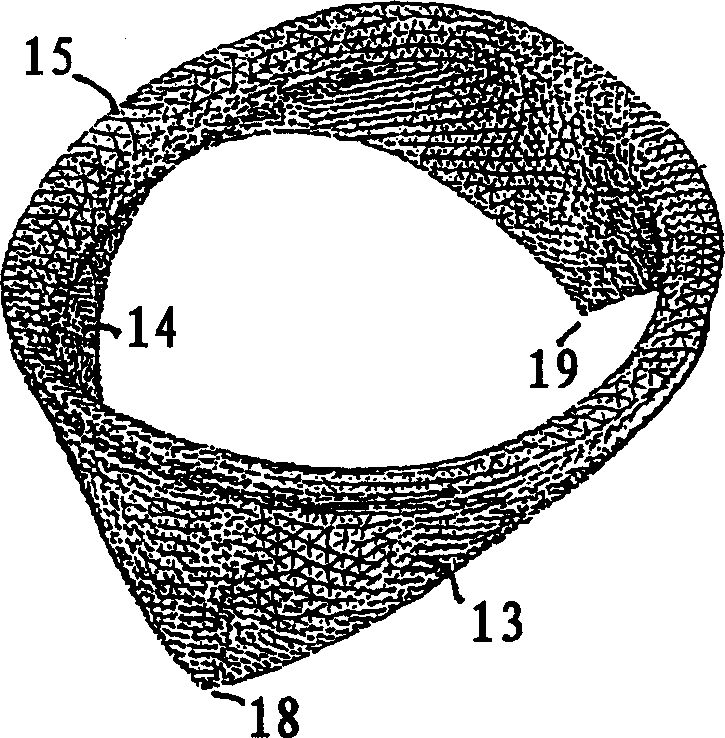

[0014] The prosthetic mitral heart valve consists of a support housing 10 with two (not shown) leaflets made of plastic, preferably polyurethane, or real material, which are fixed to the side posts On the end faces 11,12 of the integral walls 13,14. The support housing 10 is made of a thermoplastic, preferably polyurethane, which is produced by slightly bending the elastomer, for example by injection molding. The support shell is in one piece and has a base ring 15 whose inner edge is rounded outwards in a manner known from the prior art. To improve the fastening of the seam ring, the base ring has groove-shaped recesses 16 . In contrast to the mitral heart valve described in WO 97 / 49355, however, the walls 13, 14 are not aligned uniformly perpendicular to the base ring base, but are inclined by an angle α of approximately 15° (cf. in particular FIG. 5 ). Such inclination is characterized by the fact that the plane connecting the line 17 of each lateral post tip 18 and 19 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com