Device for sterilising packaging using hydrogen peroxide

A hydrogen peroxide and packaging technology, applied in disinfection, packaging sterilization, chemistry, etc., can solve the problems of high cost and complexity of pipelines, improper vaporization of hydrogen peroxide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

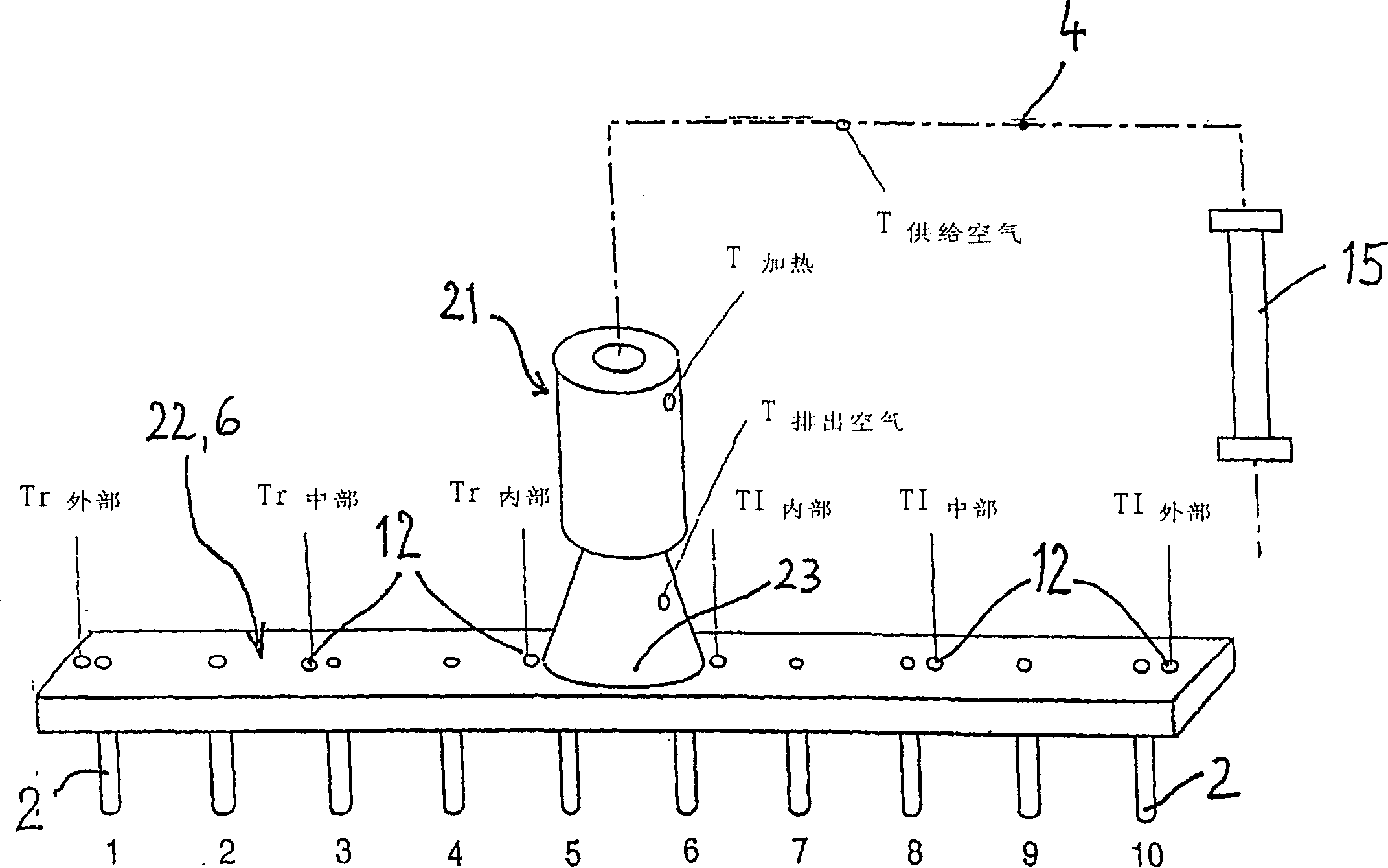

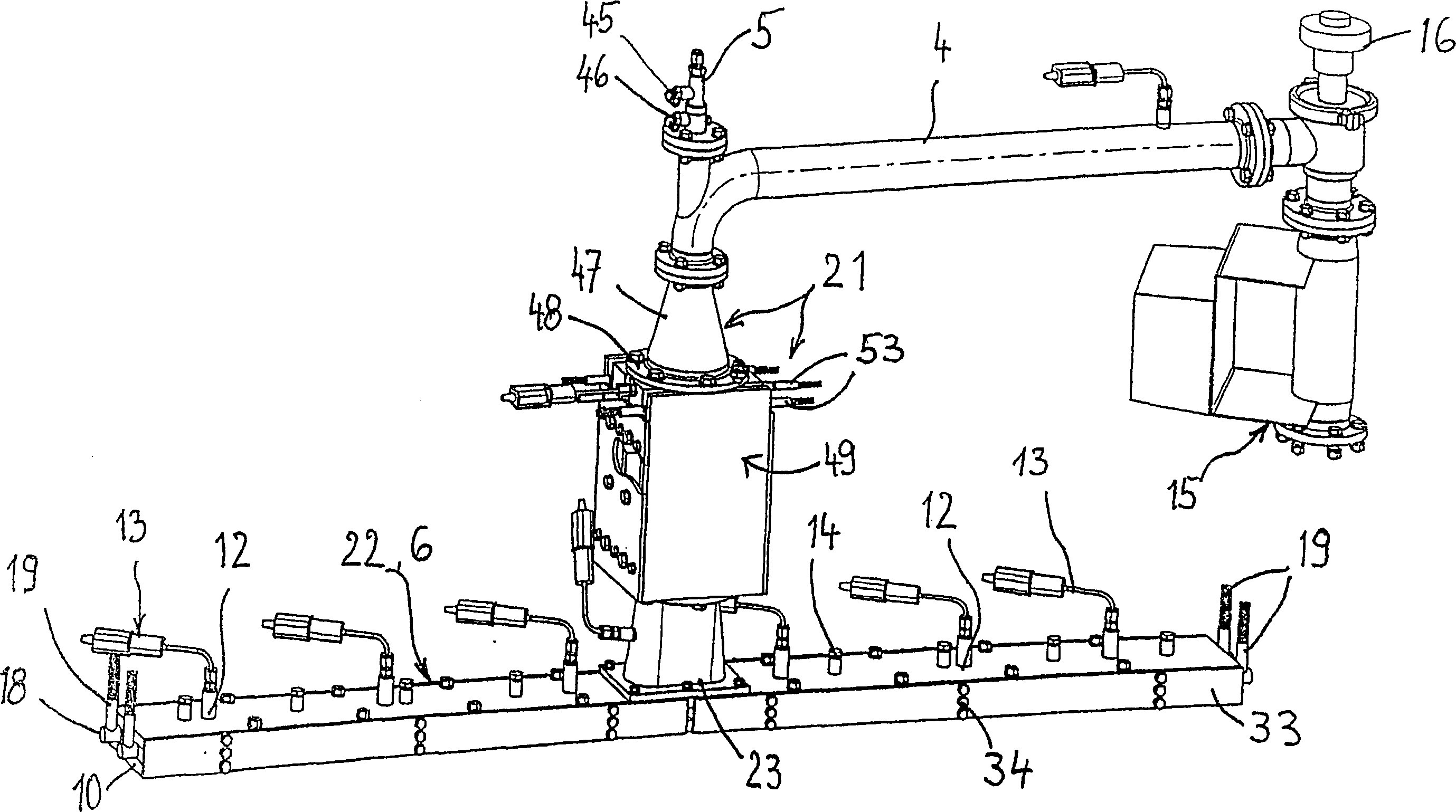

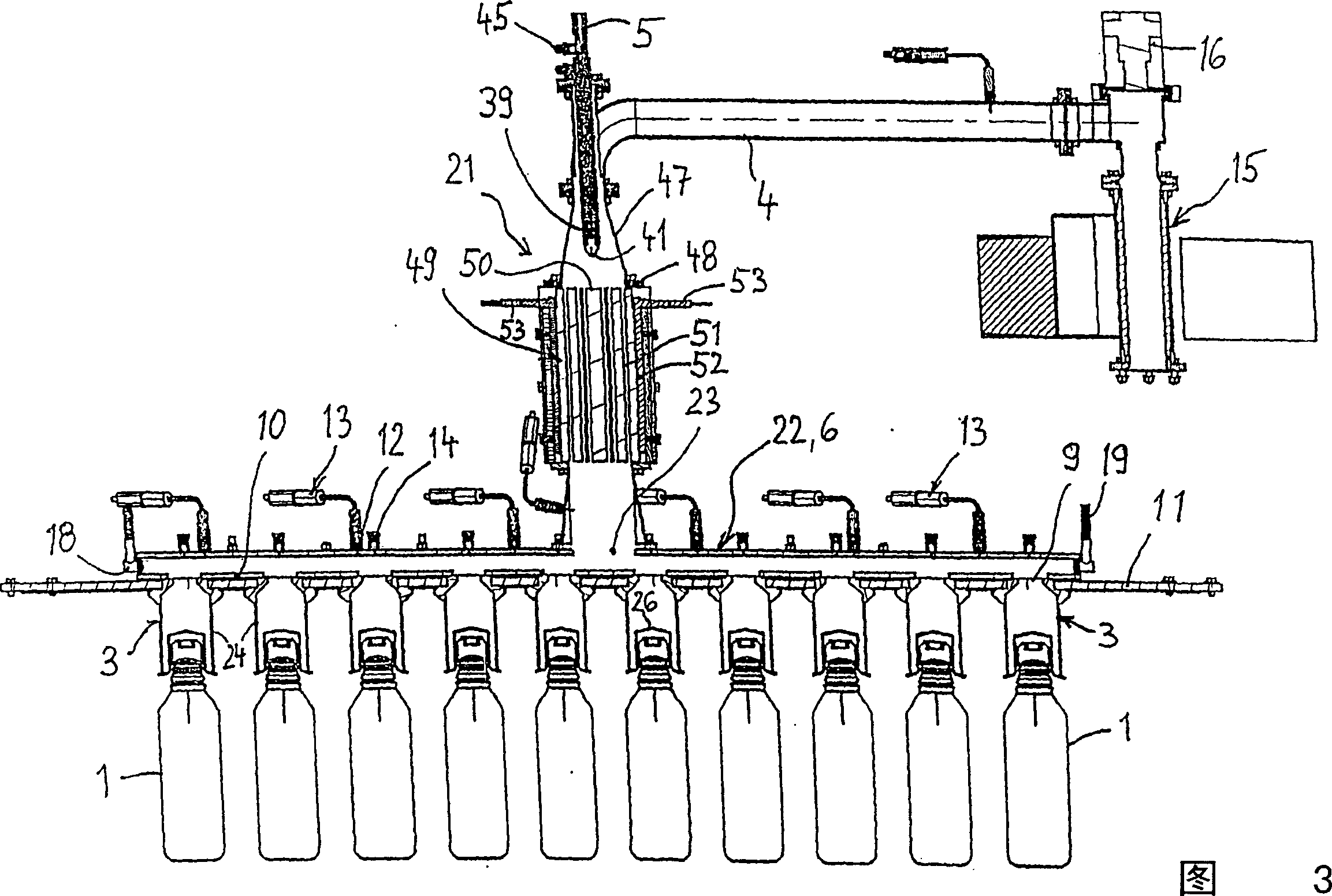

[0043] In the preferred embodiment shown in the drawings, for simultaneous sterilization operations, as shown in FIG. 3 , 10 packages 1 are lined up one behind the other under the corresponding nozzle 2 or 3 . Sterilized hot air as carrier gas on the one hand and liquid hydrogen peroxide on the other hand lead via supply lines 4, 5 to a device 21 for thermally vaporizing the hydrogen peroxide and mixing it with the hot air In this way, the adjusted gas mixture can finally pass into the distribution line, which is generally indicated by reference numeral 22, and from there into the nozzles 2,3. From the upstream position 23 for infeeding the regulated gas mixture, as figure 1 As shown in FIG. 3 , the gas mixture passes through the distribution line 22 from a position 23 arranged at the center of the distribution line 22 toward the left in the left half, and in the right half toward the right, thereby leading to the left and right outer sides of the distribution line 22 respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com