Central buffer coupling device

A coupling device and housing technology, which is applied in the field of intermediate buffer coupling devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

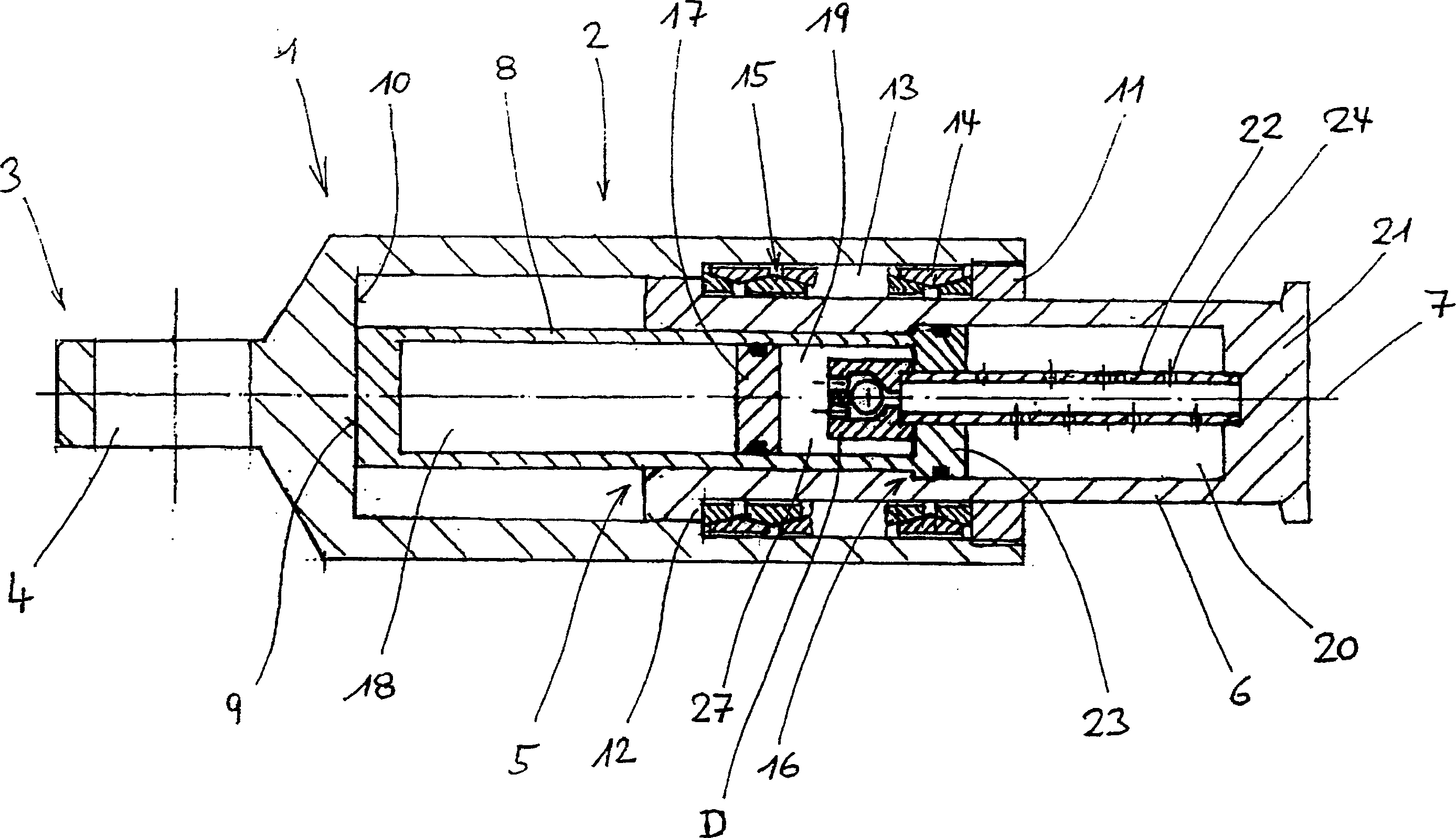

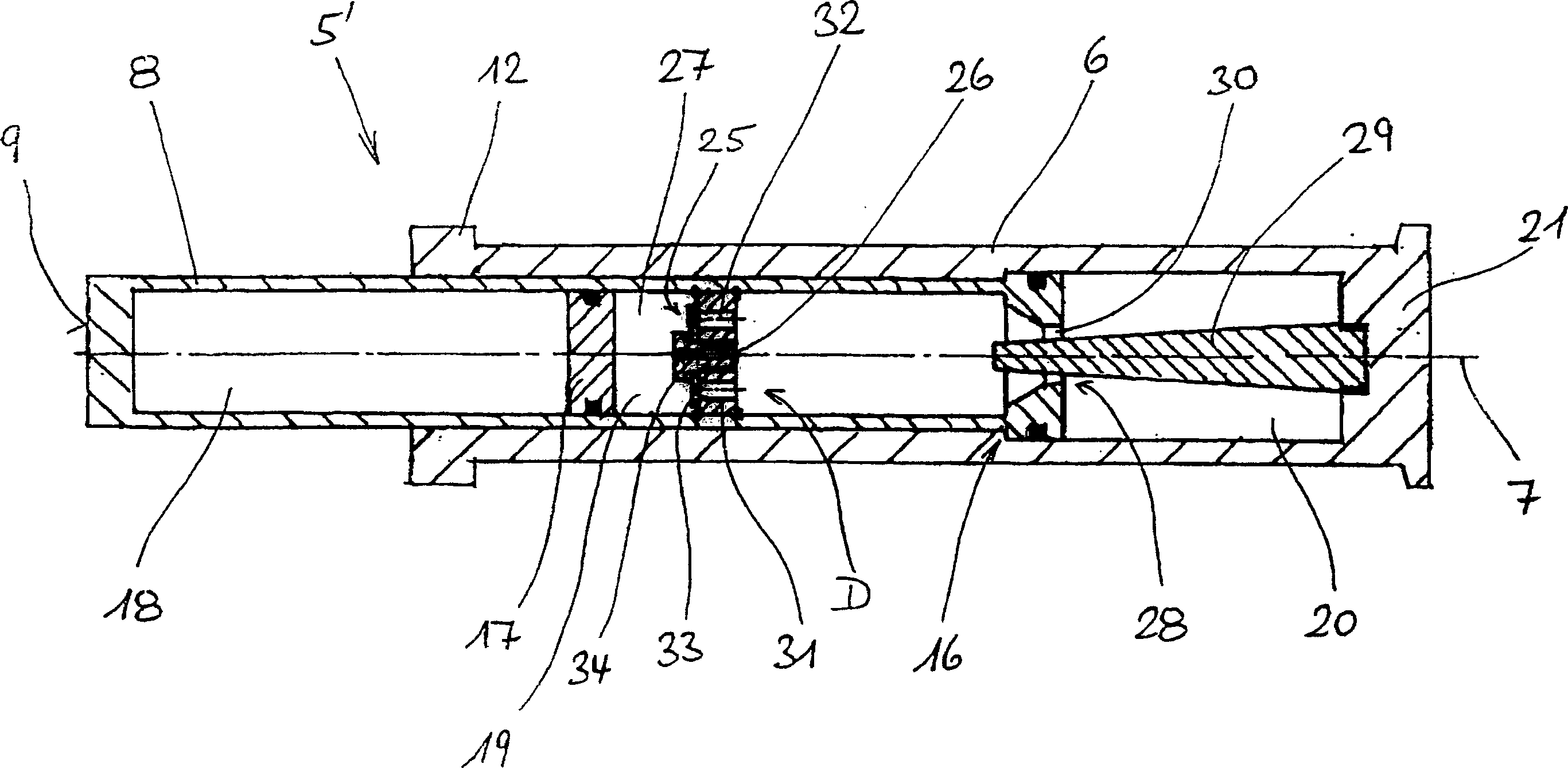

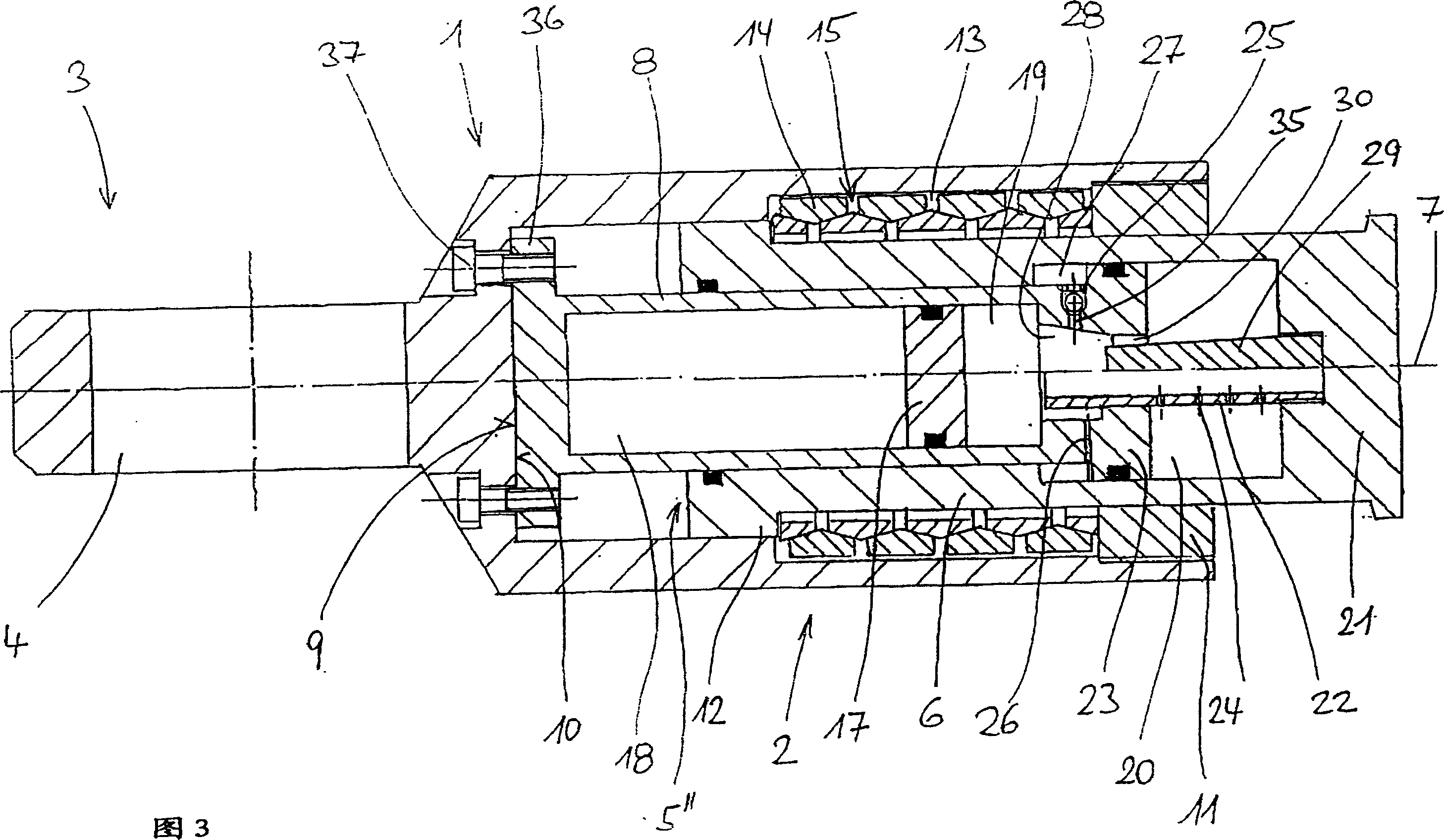

[0029] according to figure 1 The intermediate buffer coupling device comprises a housing 1 with a cylindrical section 2 and a connecting section 3 . In this known manner, the connection section 3 has a suitable eye ring 4 for receiving a ball joint, which allows the housing 1 not only to travel in a horizontal plane (curved lines) with respect to a locomotive equipped with an intermediate buffer coupling. ) and swings in a vertical plane (pop-in).

[0030] A damping sleeve 5 is arranged inside the cylindrical section 2 in the housing 1 . This damping sleeve comprises a cylindrical part 6 as main part and a hollow piston 8 which is guided displaceably along an axis 7 within this cylindrical part 6 . The hollow piston 8 is supported with its end face 9 on a bearing face 10 of the housing 1 . A cylindrical part 6 of the damping sleeve 5 projects out of the housing 1 ; this cylindrical part 6 is guided displaceably in the housing 1 along an axis 7 . For this purpose, on the on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com