Commutator motor

A commutator, motor technology, applied in the direction of DC commutator, electric components, electromechanical devices, etc., can solve problems such as increasing the output level of magnetic sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Referring now to the accompanying drawings, a description will be given of specific embodiments of the present invention.

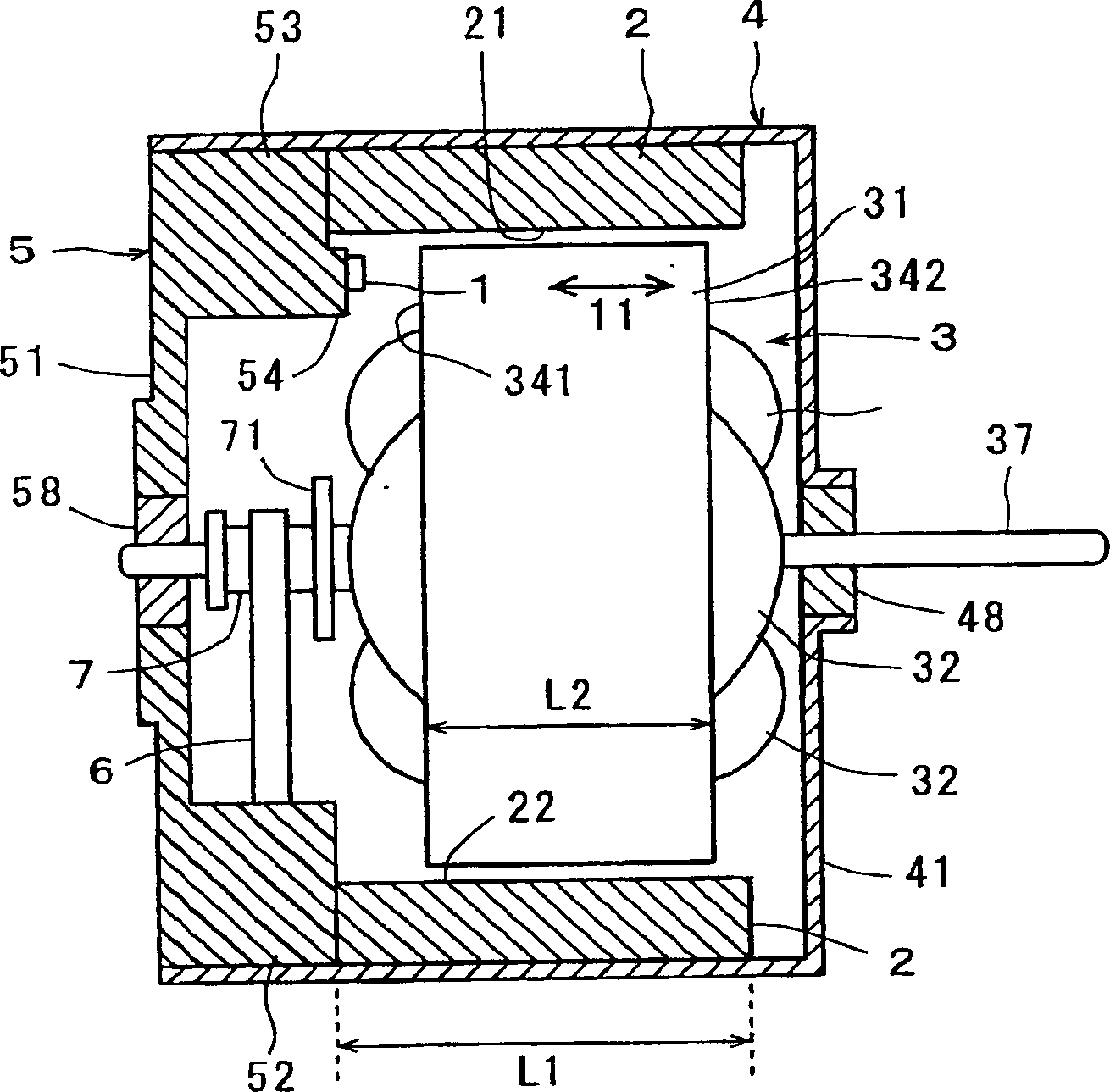

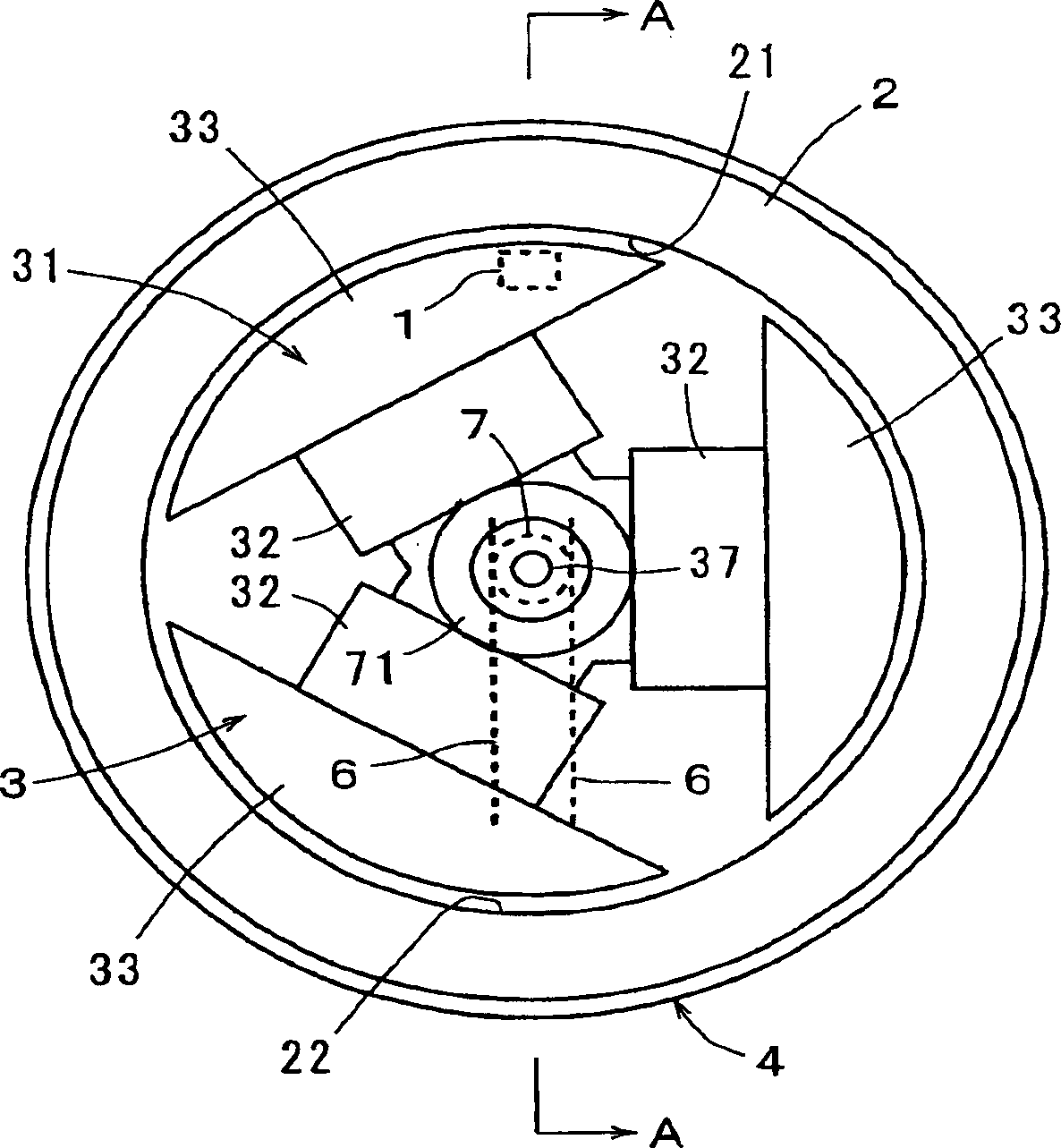

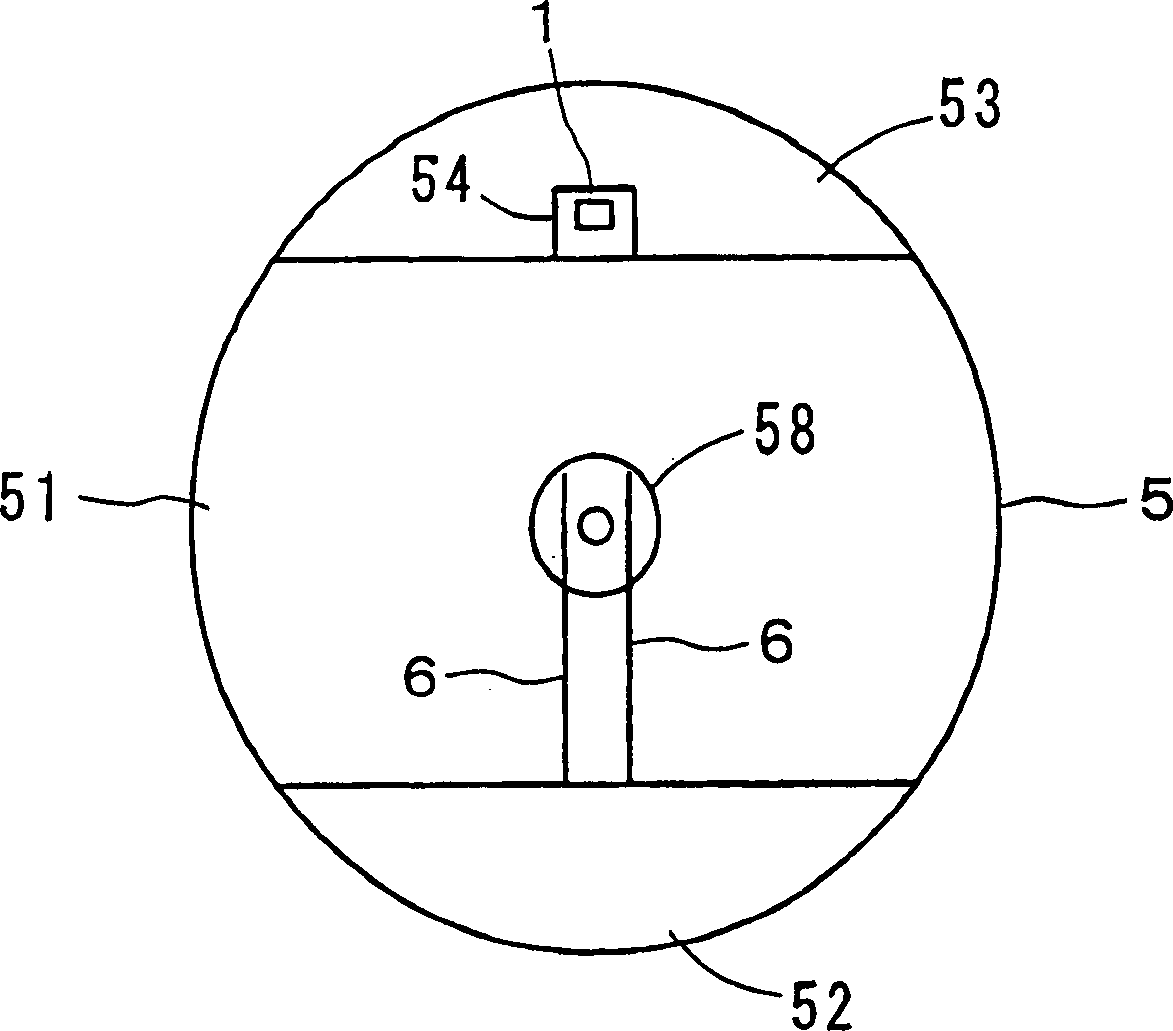

[0037] Figure 1A and Figure 1B is a block diagram illustrating a first embodiment of the commutator motor according to the present invention. Figure 1B shows the shape seen from the rear of the commutator motor, while Figure 1A shows along the Figure 1B A cross-sectional view taken along line A-A of ; in addition, figure 2 It is a shape drawing of the end frame plate seen from the inside.

[0038] In the drawing, an annular permanent magnet 2 for forming a field magnet is fixed to the inner periphery of a substantially cylindrical motor case 4 whose one end portion is closed. The rotor 3 is rotatably supported by a bearing 58 provided on the end frame plate 5 , and a bearing 48 is provided on the disc-shaped front plate 41 of the motor case 4 . The rotor 3 has a rotor core 31 fixed to a motor shaft 37 , and the rotor core 31 has three a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com