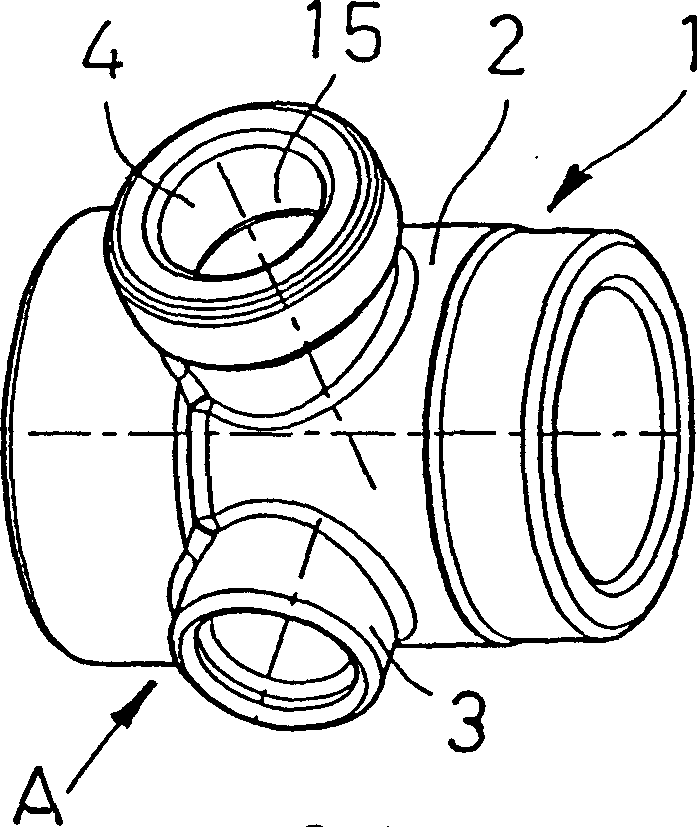

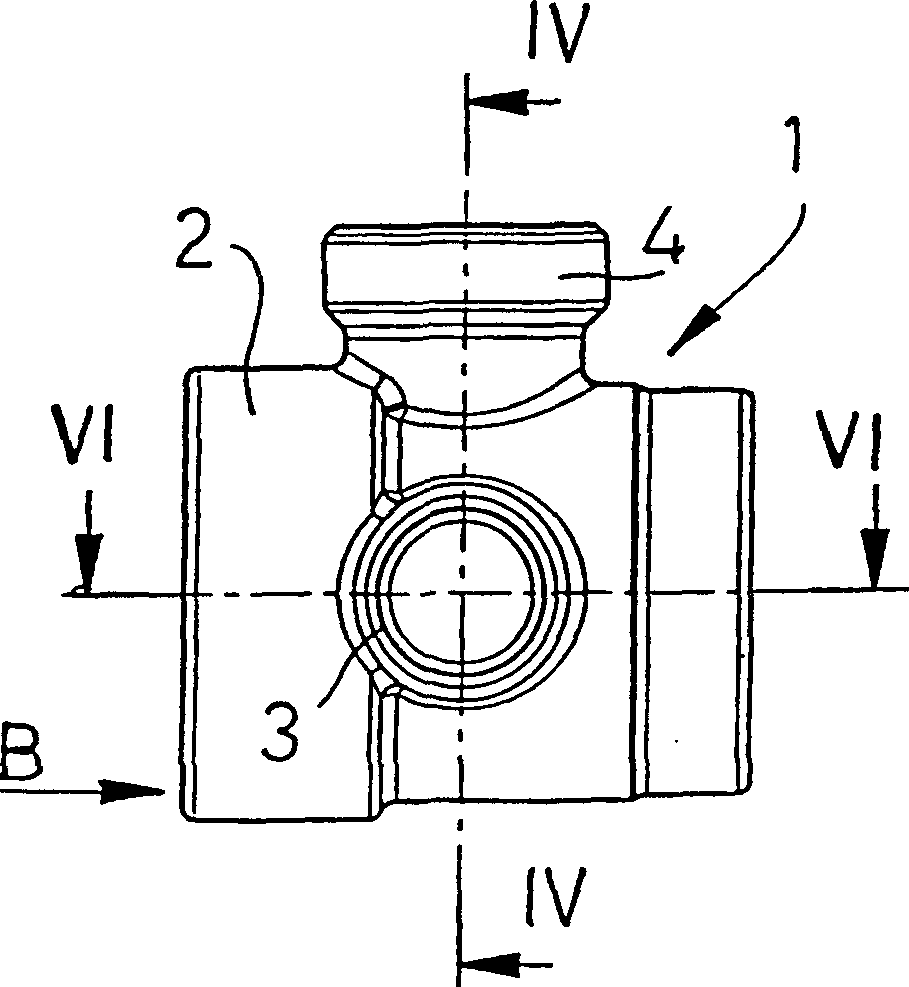

Modular manifold for heating and sanitary systems

A modular, manifold technology, applied in piping systems, pipes, branch pipelines, etc., can solve the problems of using tools, time-consuming plastic manifolds, etc., to reduce assembly time, reduce pressure loss, and reduce weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 21

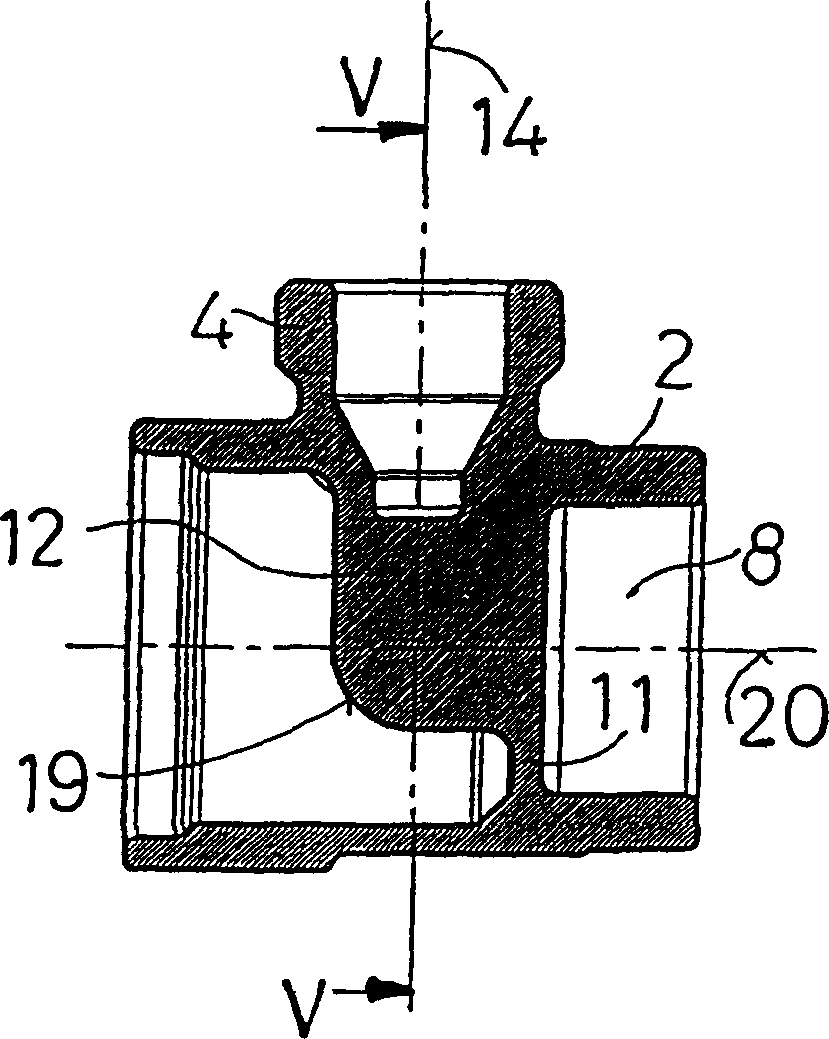

[0080] The tap 4 can also be constructed like the tap 4A, ie a fixture for mounting metal pipes, plastic pipes, composite or multilayer pipes, etc.

[0081] In order to enhance the reduction of pressure losses caused by friction and indirectly achieve better dimensions and better efficiency of the pipes of heating or sanitary systems, no Boss 12 and first and second cup-shaped end chambers 6 , 8 , while the latter of said connecting pipe 12 have substantially the same inner diameter, so that inside module body 2 a substantially cylindrical straight-through pipe 16A is obtained.

[0082] Further structural features of the manifold modules 70, 71 and 80 can be deduced from FIGS. 7 to 13 and their above description.

[0083] In another aspect of the present invention, a flow meter or the like or a thermostatic element or a piston head end of the automatic control switch 34 may also be installed in the adjusting joint 3 of the installation switch 34 .

[0084] Each of the two com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com