Piston pin mounting structure for sealed compressor

A mounting structure, piston pin technology, applied to parts of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc., to achieve the effects of preventing deformation, long-term fixed bonding, and suppressing the tendency to rotate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The piston pin installation structure of the hermetic compressor of the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments:

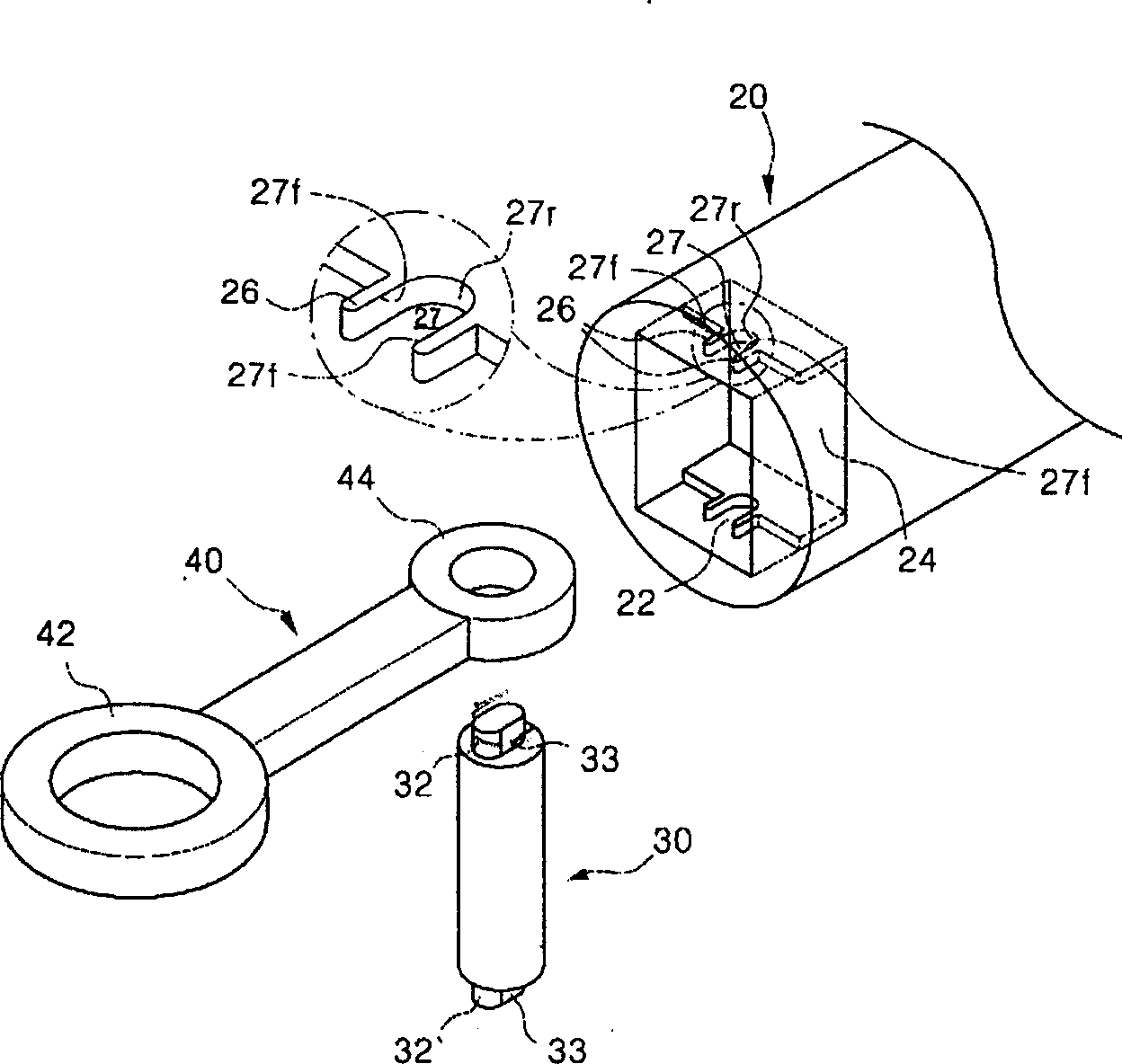

[0020] like image 3 , 4 As shown, the piston 20 performs rectilinear reciprocating motion inside the compression chamber, and the piston 20 forms a cylinder shape. A connection space 22 is formed inside the rear end of the piston 20 , and the connection space 22 is formed opening to the rear of the piston 20 . Inside the connection space 22 is formed a collision preventing portion 24 that prevents collision between the small end portion 44 of the connecting rod 40 and the piston 20 . The anti-collision portion 24 is recessed inwardly in the connection space 22 and is located at one end of the small end portion 44 .

[0021] The upper and lower parts of the anti-collision part 24 are formed with a bandage part 26 , and the bandage part 26 plays a role of fixing the pisto...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap